Hydraulic system of continuous string coiled tubing unit

A hydraulic system and operating machine technology, applied in the field of hydraulic systems, can solve problems such as circuit throttling power loss, overflow power loss, low efficiency, etc., and achieve the effects of effective oil temperature control, sufficient oil return heat dissipation, and high transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

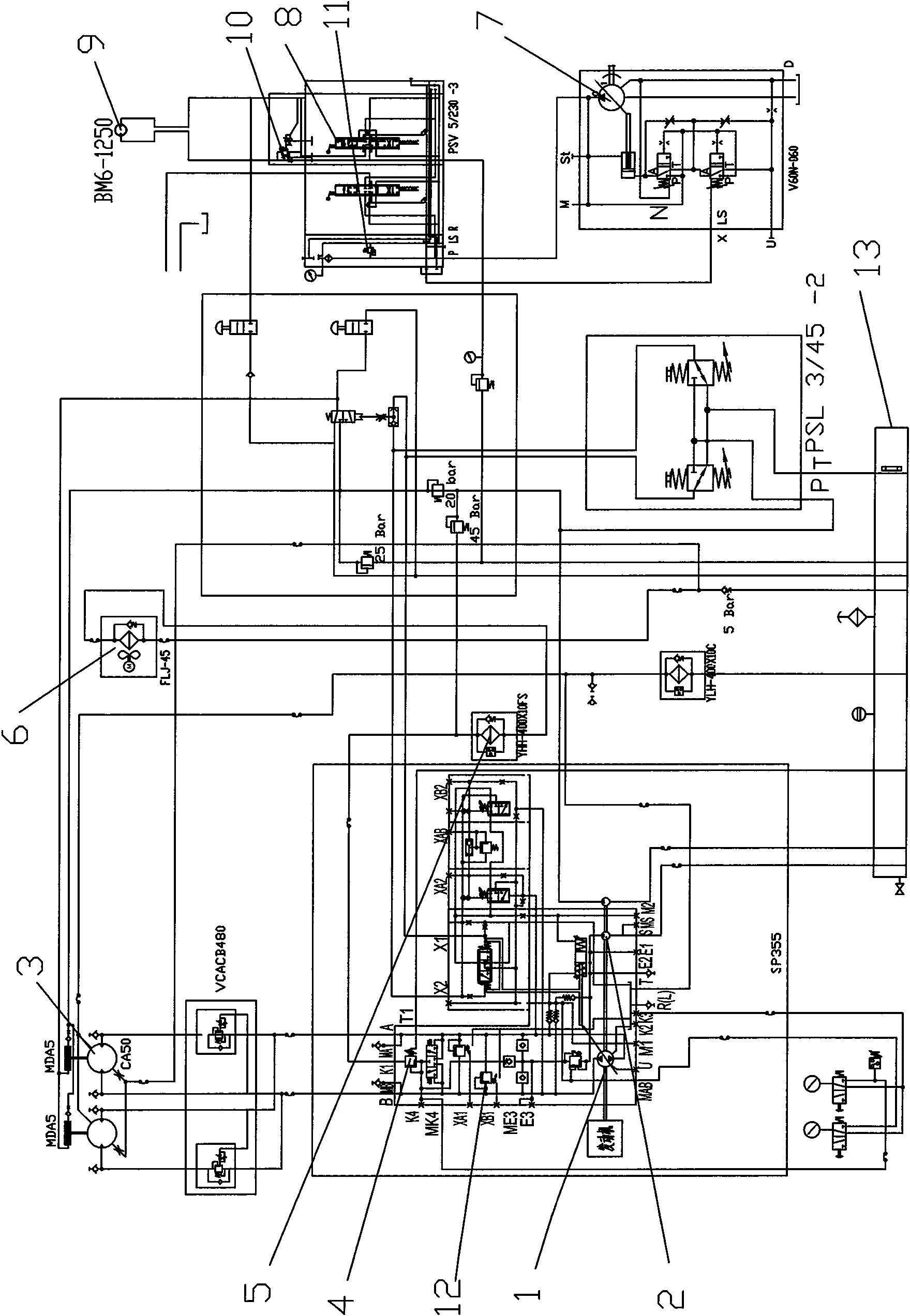

[0016] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the hydraulic system of a coiled tubing machine consists of an injection head hydraulic subsystem and a reel hydraulic subsystem. The injection head hydraulic subsystem is a closed volume speed regulation subsystem, including a two-way variable plunger pump 1 , quantitative radial piston motor 3, relief valve 4, oil filter 5, cooler 6, auxiliary charge pump 2 and safety valve A12, the outlet of the two-way variable piston pump 1 is connected to the quantitative radial piston motor The inlet of 3 is connected through the oil pipe, and the outlet of the quantitative radial piston motor 3 is divided into two paths, one path is connected with the inlet of the two-way variable plunger pump 1 through the oil pipe, and the other path is connected with the inlet of the relief valve 4 through the oil pipe, The overflow valve 4 is sequentially connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com