Elevating mechanism of lifting bar of computerized flat knitting machine

A lifting mechanism and needle lifter technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of many moving links of needle lifter lifting, complicated structure, impact of needle lifter, etc., to achieve convenience and Fast cleaning, less movement links, and the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

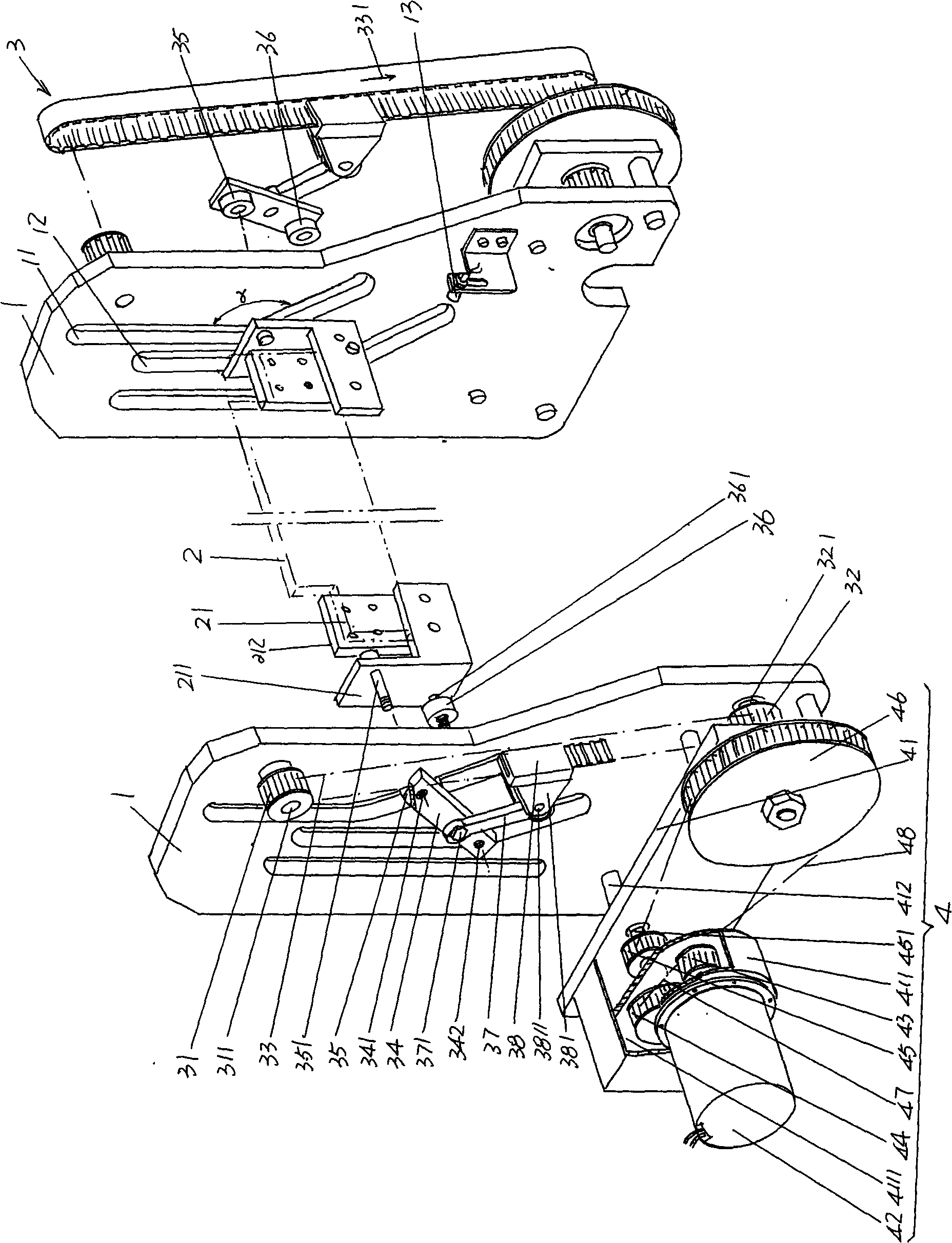

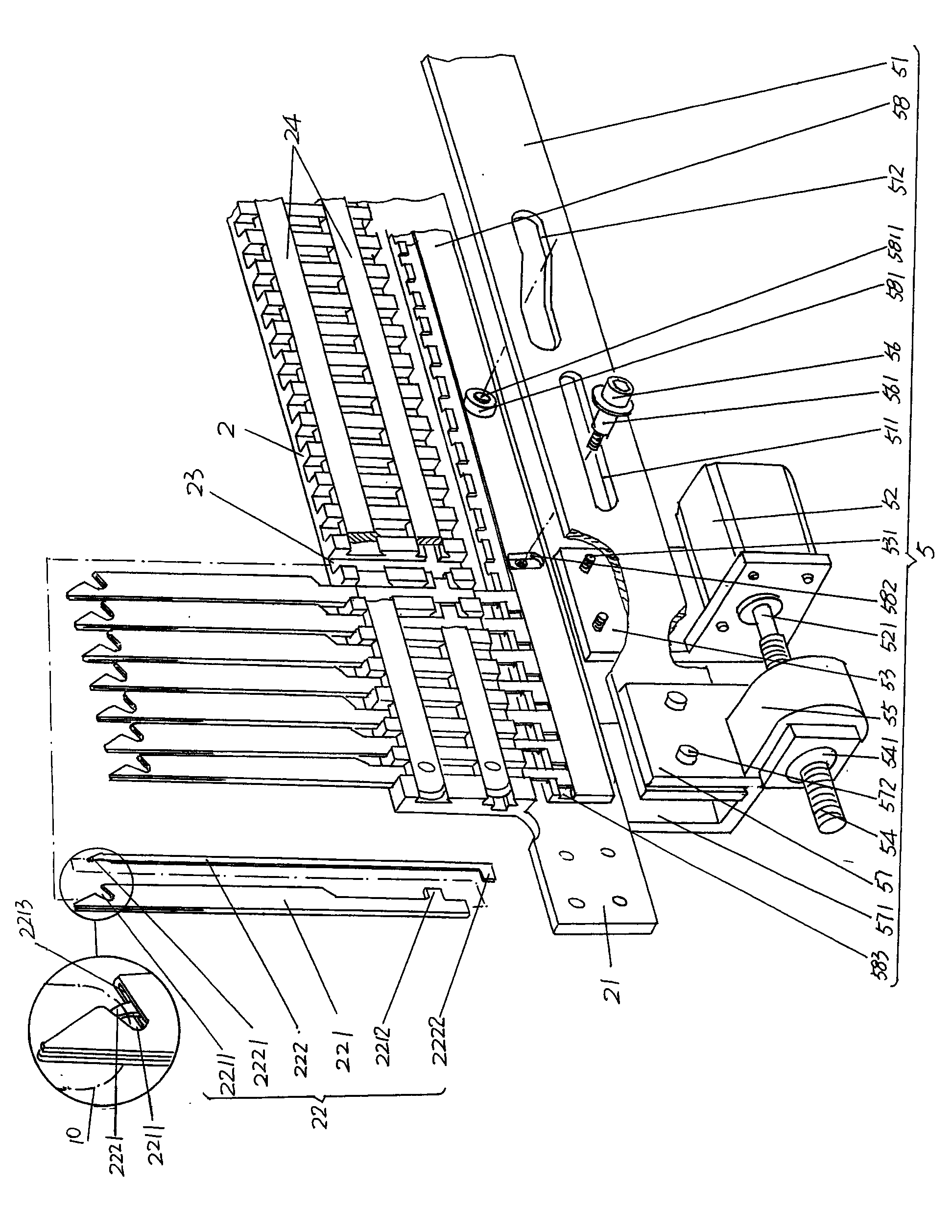

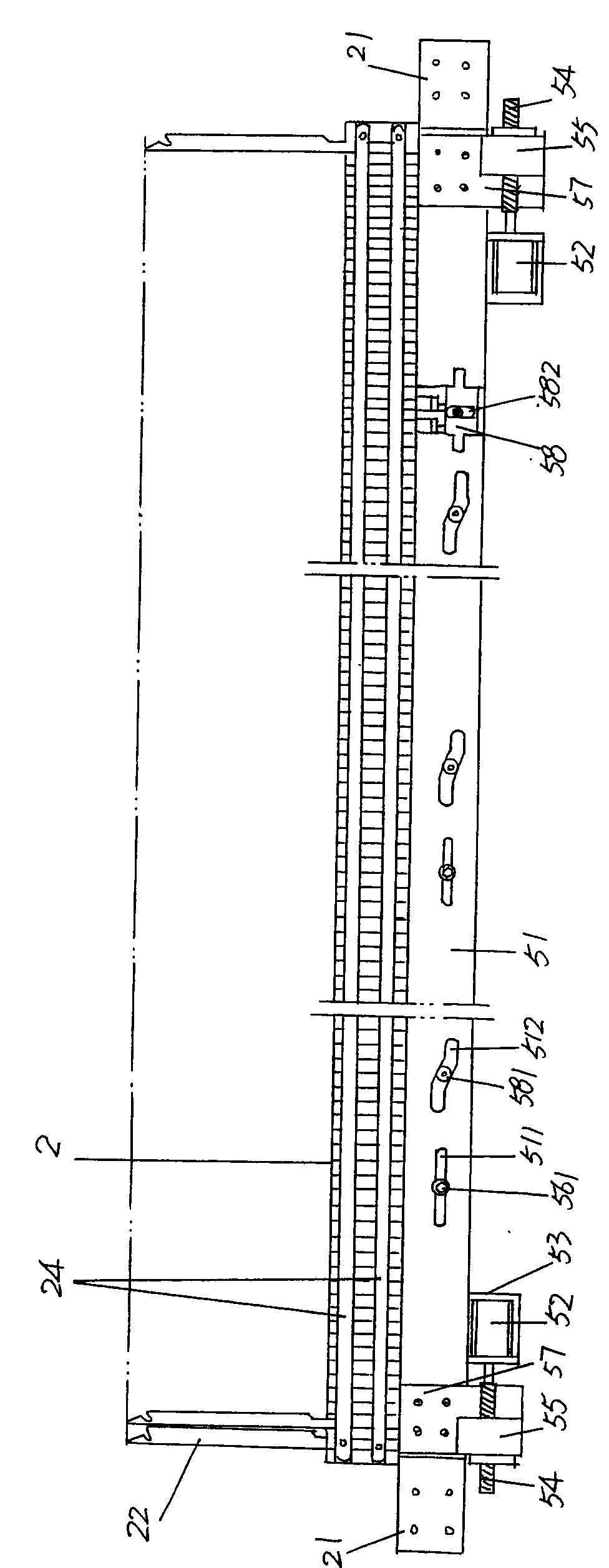

[0020] please see figure 1 , a pair of wallboards 1 is provided, and the pair of wallboards 1 is fixed to the computerized flat knitting machine below the cabinet 6 ( Figure 4 The corresponding two sides of the length direction of shown), the distance between a pair of wallboards 1 is suitable for the length of needle lifting board 2. Since the shape, structure, installation method and working principle of a pair of wallboards 1 are completely the same, the applicant will choose one to describe in detail below. Since the width of the upper end of the wallboard 1 is smaller than that of the lower end, there is a trend of gradually widening from top to bottom, so the shape of the wallboard 1 tends to be pipa-shaped. The upper end of the height direction of the wallboard 1 is provided with first and second moving grooves 11, 12, and the upper ends of the first and second moving grooves 11, 12 are straight grooves, while the lower ends are inclined grooves, and the straight groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com