Full-automatic production line for synchronous furnace multi-band bright quenching of bimetal band saw blades

A bimetallic belt and production line technology, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems of waste and low production efficiency of quenching process, and achieve the effect of reducing production cost, high degree of automation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

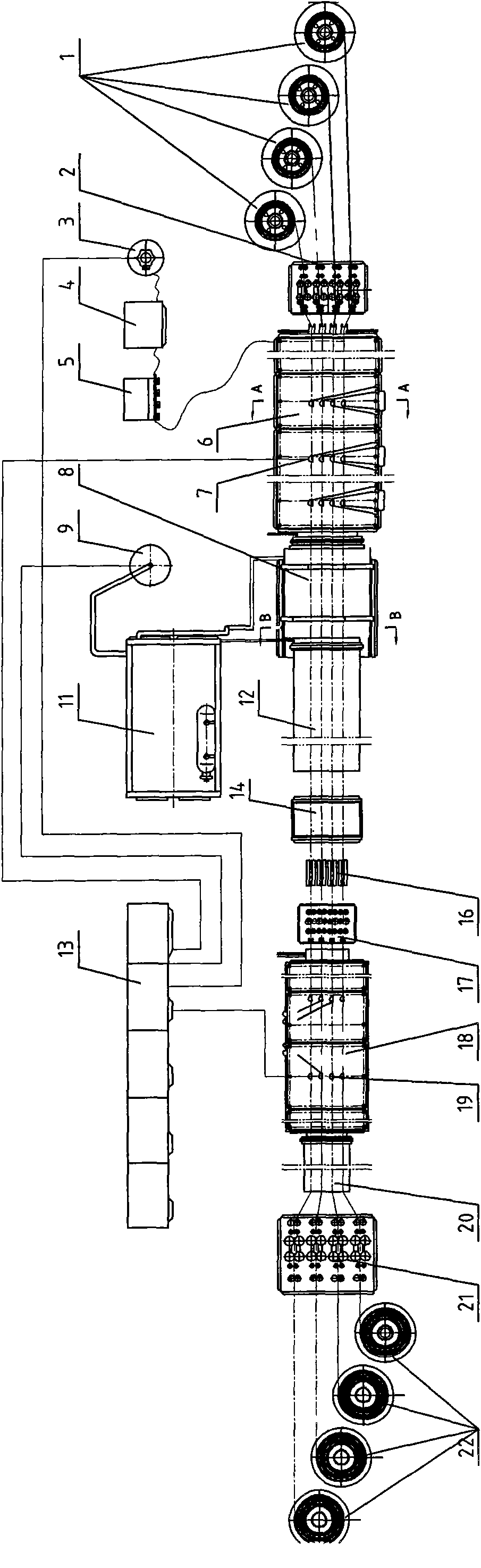

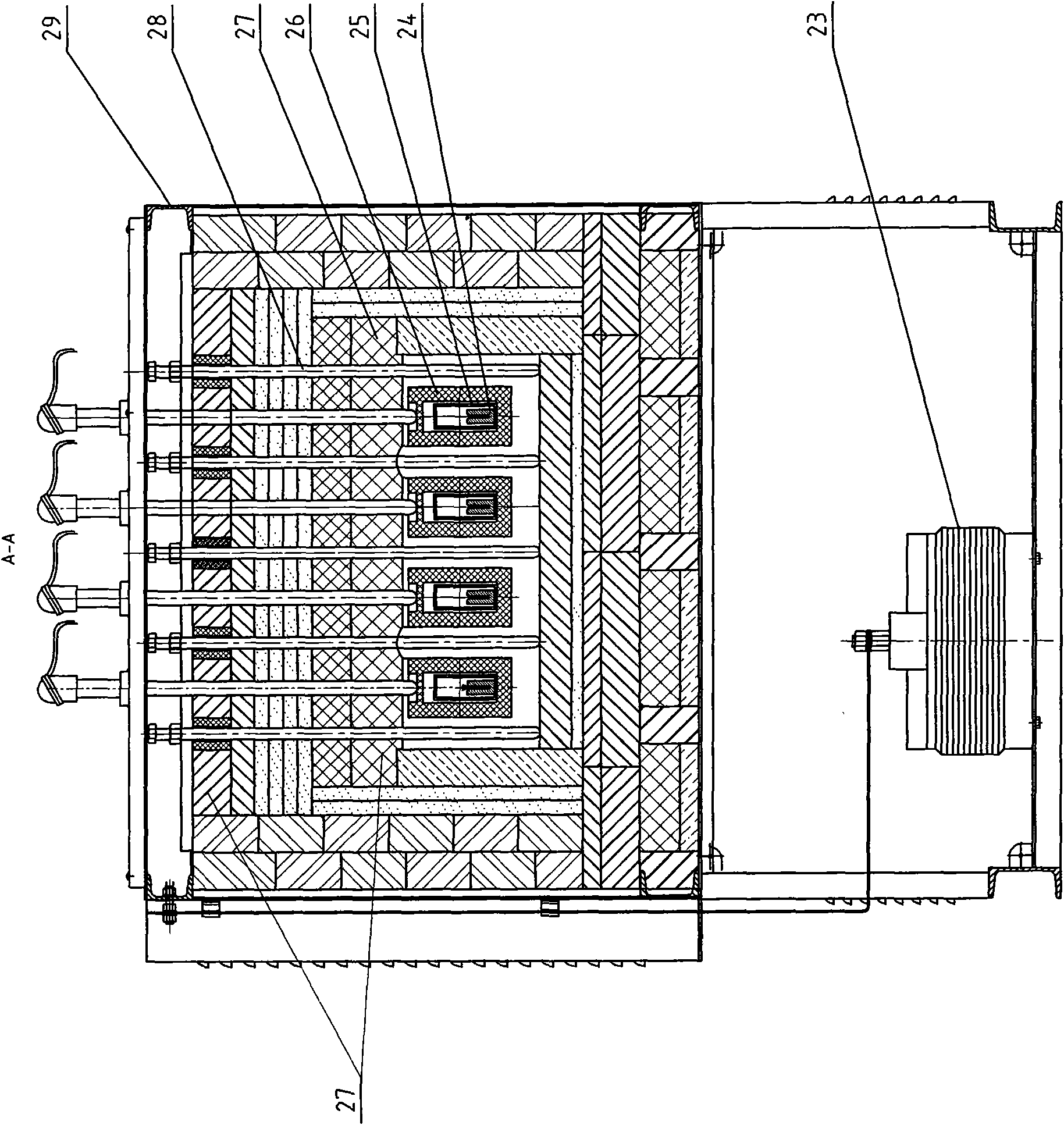

[0009] Specific implementation mode one: as figure 1 , image 3 and Figure 4 As shown, the multi-band bright quenching full-automatic production line for bimetallic band saw blades described in this embodiment includes a cooling tower 9, a cascade refrigeration unit 11, a nitrogen generating unit 3, an evaporator 4 and a nitrogen distribution unit. Nitrogen supply device, temperature control system 13 and haul-off machine 21 formed by sequential connection of device 5; said production line also includes N discharging trays 1, damper 2, box-type heating furnace 6, multiple high-temperature thermocouples 7, cryogenic Quenching device 8, first water cooling jacket 12, guider 14, box type tempering furnace 18, multiple low temperature thermocouples 19, second water cooling jacket 20 and N receiving pans 22; the box type heating furnace 6 consists of a shell 29. Insulation layer 27, a plurality of silicon molybdenum rod heating elements 28 and N heating units, each heating unit ...

specific Embodiment approach 2

[0012] Specific implementation mode two: as figure 1 , image 3 and Figure 4 As shown, the production line in this embodiment further includes a cooler 16 disposed between the guide 14 and the box-type tempering furnace 18 . The cooler 16 is provided in order to further achieve the cooling effect. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: as figure 1 , image 3 and Figure 4 As shown, the production line in this embodiment further includes a counter 17 , and the counter 17 is arranged between the cooler 16 and the box-type tempering furnace 18 . The counter 17 can measure the length of the band saw blade, display the line speed and measure the output, etc. Other components and connections are the same as those in the second embodiment.

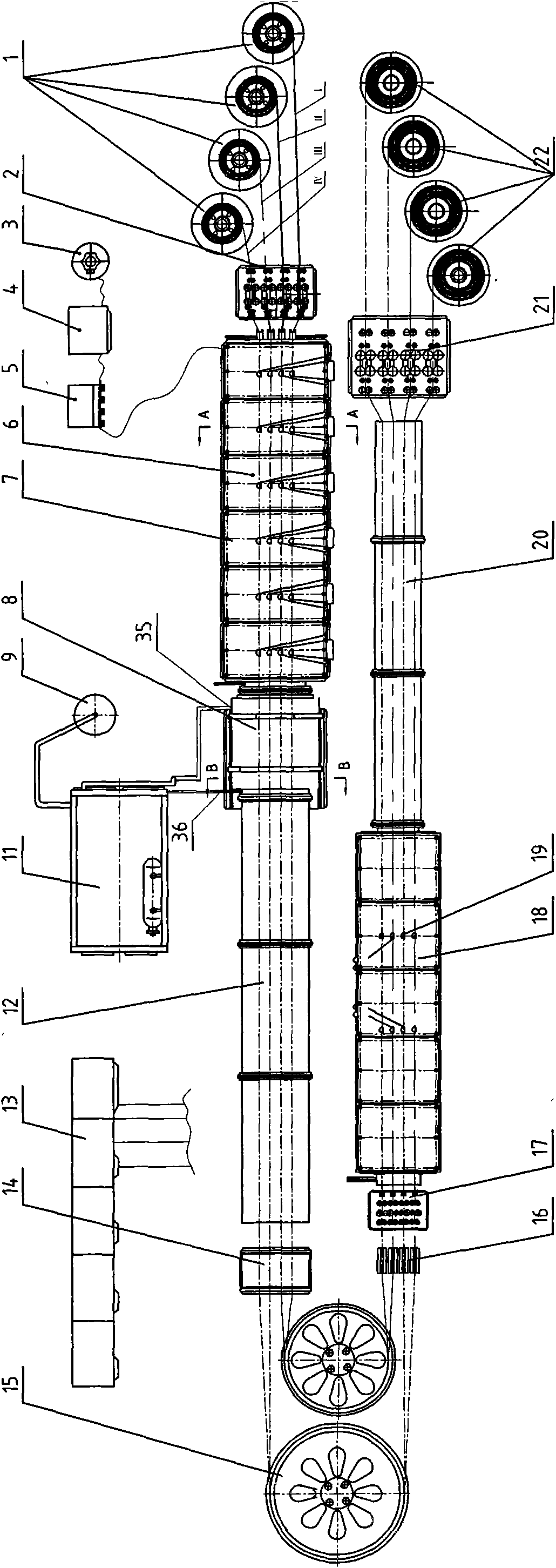

[0014] Specific implementation mode four: as figure 2 As shown, the production line in this embodiment also includes a set of steering wheels 15, and the set of steering wheels 15 is arranged between the guide 14 and the cooler 16 in a straight line, and each steering wheel in the set of steering wheels 15 The diameter of the steering wheel gradually decreases from the outer end to the inner end, and the number of the set of steering wheels 15 is at least two. The effect of one group of steering wheels 15 is that the production l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com