Rapid co-detection device of sample

A sample and joint inspection technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems that the sample joint inspection process cannot be really fast, increase production costs, etc., and achieve the goal of avoiding the spread of pathogens in inspection products, easy to carry, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

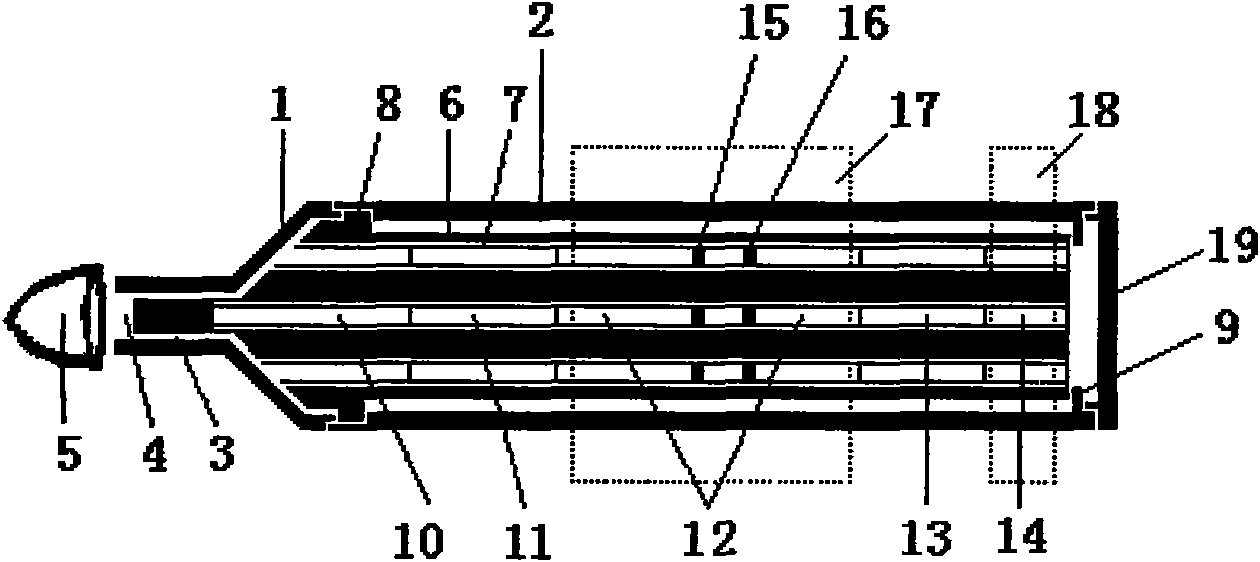

[0035] Example 1 The structure of the sample rapid joint inspection device (illustrated in conjunction with the accompanying drawings)

[0036] figure 1 It is a structural view of the preferred scheme 1 of the sample rapid joint detection device of the present invention. The device includes a sample suction head 1 and a detection tube 2 sleeved on the rear end of the sample suction head 1 . The front end of the suction head 1 has a thin tube suction nozzle 3 . The suction nozzle 3 is provided with a sample suction port 4 for sample suction. The front end of the suction nozzle 3 can be covered with a rubber protective cap 5. During the test, the rubber protective cap 5 is removed to expose the sample suction port 4, and the sample joint inspection can be carried out by dipping the suction nozzle 3 in the test product. A test strip attachment column 6 is built in the device, and the surface of the test strip attachment column 6 has one or more longitudinal shallow grooves, a...

Embodiment 2

[0047] Example 2 Operation method of sample rapid joint inspection device

[0048] The joint inspection device (including figure 1 , figure 2 , image 3 , Figure 4 The operation and use method of joint inspection device described in the scheme) is:

[0049] (1) Take out the sample rapid joint inspection device;

[0050] (2) Remove the device head cover 20 of the device and the rubber cap 5 at the front end of the suction head to expose the sample suction port 4, and dip the suction nozzle 3 into the inspection product;

[0051] (3) Within a few minutes, observe the appearance of the built-in test strip strips in the sample color development area of the transparent plastic shell of the detection tube of the device, and judge the negative and positive test results of each index of the test product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com