High pass tissue grinder and grinding method

A grinding method and a grinding machine technology, which are applied in the grinding field, can solve the problems of poor grinding effect and complex structure of raw material samples, and achieve the effects of less cross infection, simple structure and improved grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

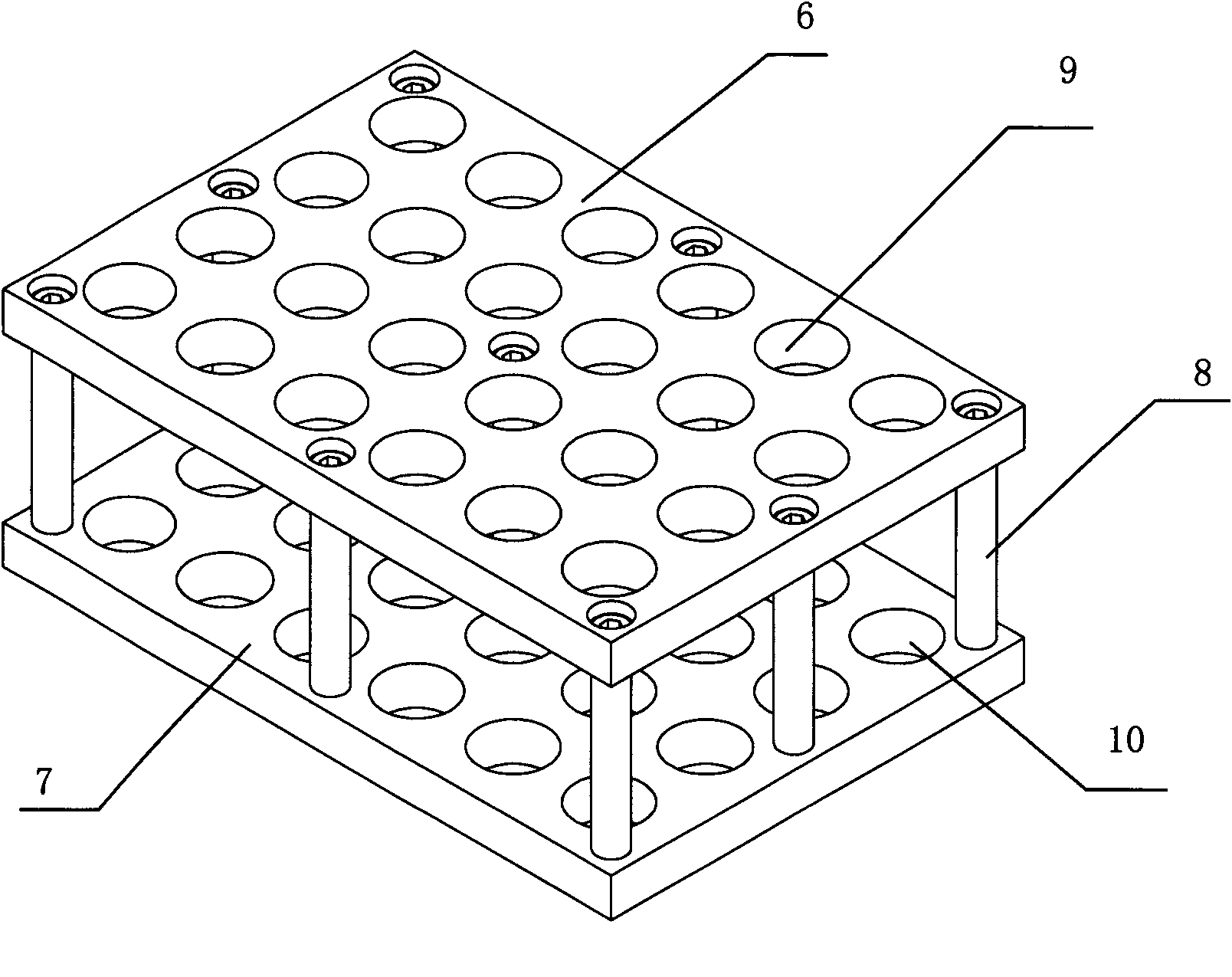

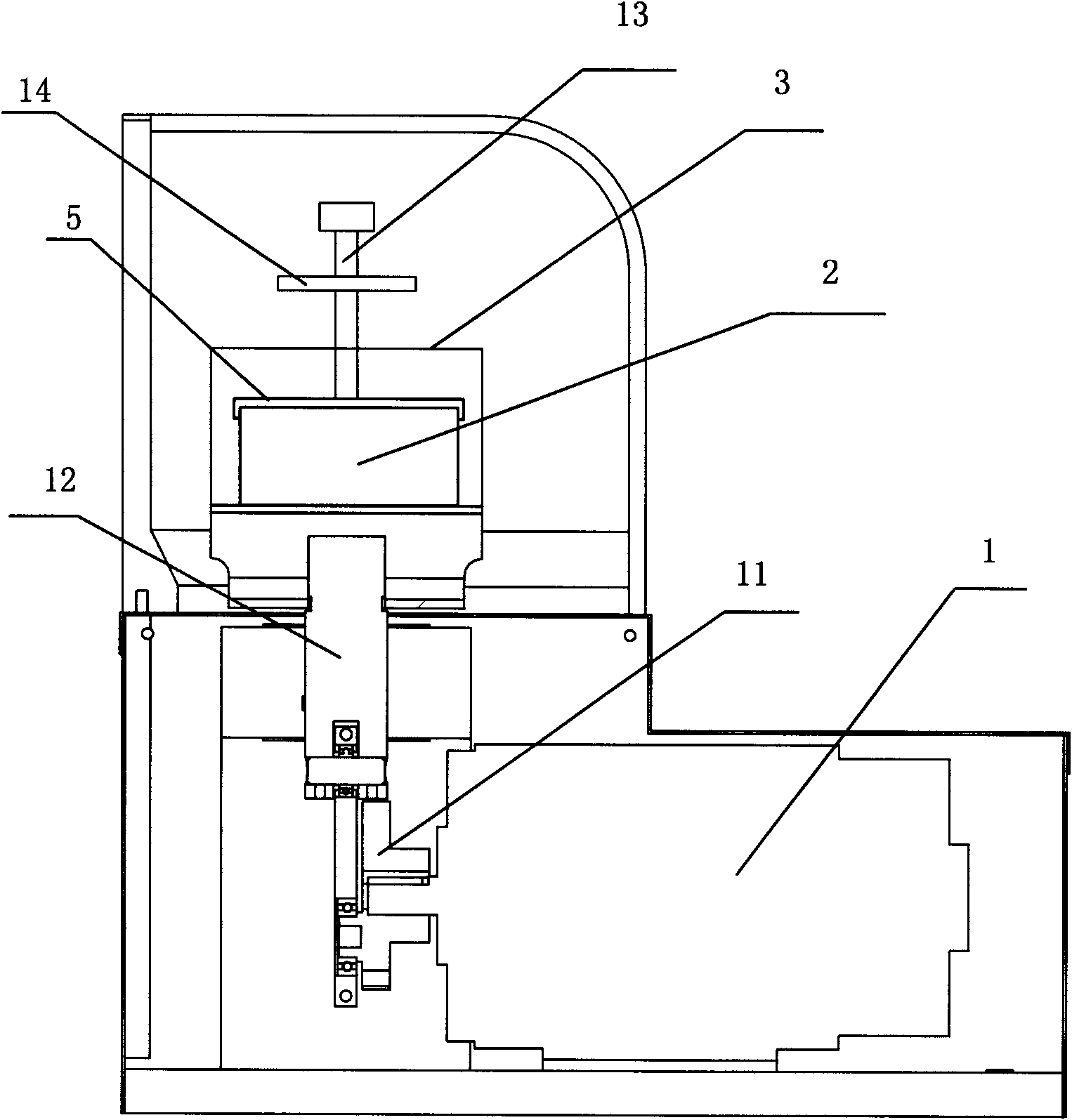

[0019] Embodiment 1: A high-throughput tissue grinder, which includes a motor 1, a bracket 3 for placing the sample box 2, and a swing mechanism. The motor 1 is connected to the bracket 3 through the swing mechanism, and the bracket 3 is provided with a device that can hold the sample box 2. A fixed fixing device, the sample box 2 is provided with a cover plate 5 that can fix the sample tube 4 . The sample box 2 comprises an upper fixed plate 6 and a lower fixed plate 7, a support column 8 is arranged between the upper fixed plate 6 and the lower fixed plate 7, a plurality of first tube holes 9 are arranged on the upper fixed plate 6, and a plurality of first pipe holes 9 are arranged on the lower fixed plate. 7 is provided with a second tube hole 10 corresponding to the first tube hole 9 . The swing mechanism includes an eccentric wheel 11 and a drive shaft 12 , the eccentric wheel 11 is arranged on the output shaft of the motor 1 , and the eccentric wheel 11 is connected wit...

Embodiment 2

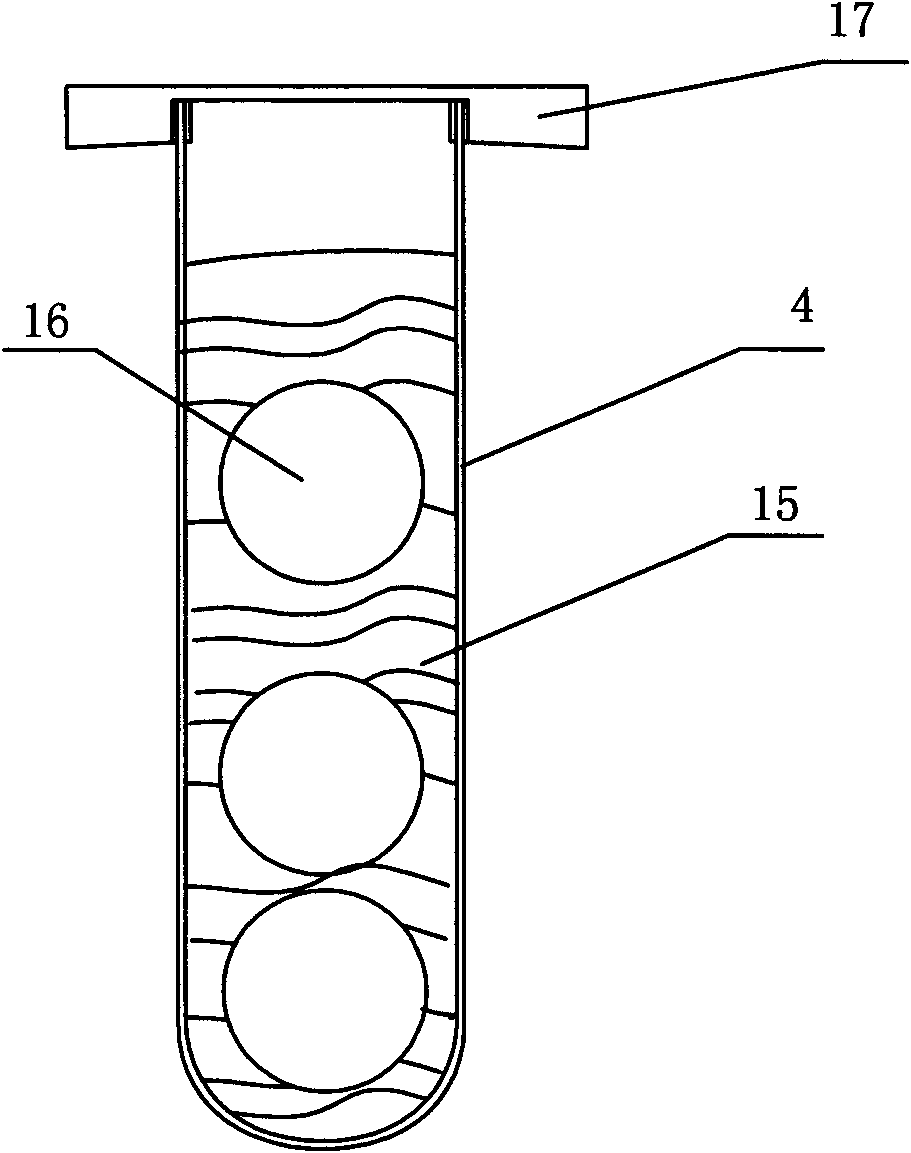

[0023] Embodiment 2: a grinding method of a high-throughput tissue grinder, which is characterized in that it comprises the following steps: (1), pouring the raw material sample 15 into the sample tube 4; (2), putting the sample tube 4 into 3 ceramic grinding balls 16, the diameter of the ceramic grinding balls 16 is between 10 mm, the diameter of the sample tube 4 is greater than the diameter of the ceramic grinding balls 16 by 1 mm, and the sample tube 4 is sealed with a cover 17; (3), pour all the raw materials The sample tube 4 of the sample 15 is inserted into the first tube hole 9 and the second tube hole 10 of the sample box 2 respectively, and then the sample tube 4 is fixed in the sample box 2 with the cover plate 5; (4), the sample box 2 Immerse in liquid nitrogen and cool for 3 minutes; (5), put the sample box 2 with a plurality of sample tubes 4 into the support 3 of the grinder, and fix the sample box 2 in the support 3 with a fixing device; (6) , Start the grinde...

Embodiment 3

[0024] Embodiment three: a grinding method of a high-throughput tissue grinder, characterized in that it comprises the following steps: (1), pouring the raw material sample 15 into the sample tube 4; (2), putting the sample tube 4 into 5 ceramic grinding balls 16, the diameter of the ceramic grinding ball 16 is between 2-10mm, the diameter of the sample tube 4 is greater than the diameter of the ceramic grinding ball 16 2.5mm, then the sample tube 4 is sealed with a cover 17; (3), all The sample tube 4 poured into the raw material sample 15 is inserted into the first tube hole 9 and the second tube hole 10 of the sample box 2 respectively, and then the sample tube 4 is fixed in the sample box 2 with the cover plate 5; (4), the The sample box 2 is immersed in liquid nitrogen and cooled for 4 minutes; (5), the sample box 2 with a plurality of sample tubes 4 is placed in the support 3 of the grinder, and the sample box 2 is fixed in the support 3 with a fixing device; (6), start ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com