Double-cylinder articulated gate mechanism

A hinged mechanism and hinged technology, used in mechanical equipment, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the problems of non-adhering flange end faces and asymmetrical force on doors, and improve rigidity. and strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Further illustrate the present invention below in conjunction with accompanying drawing.

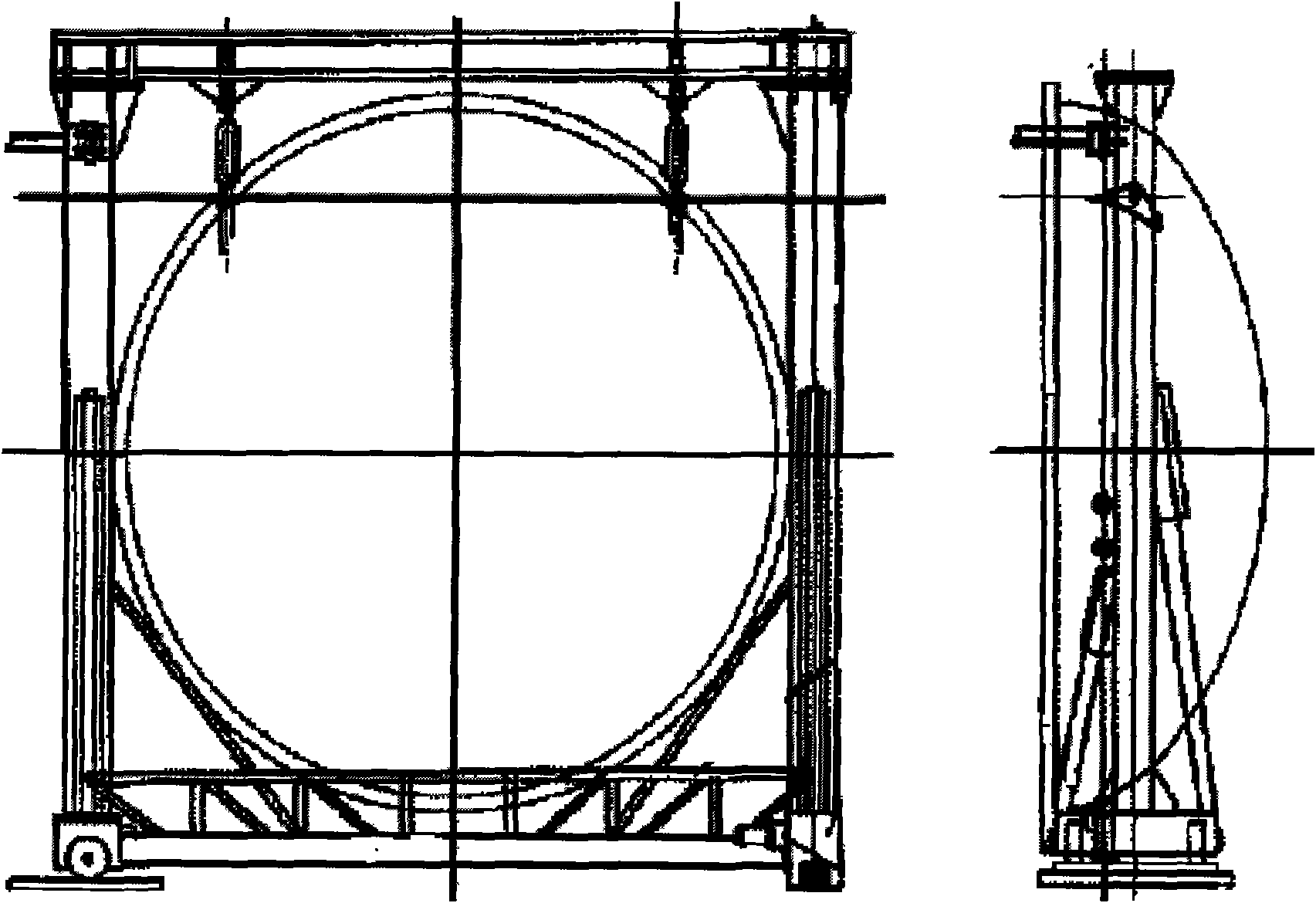

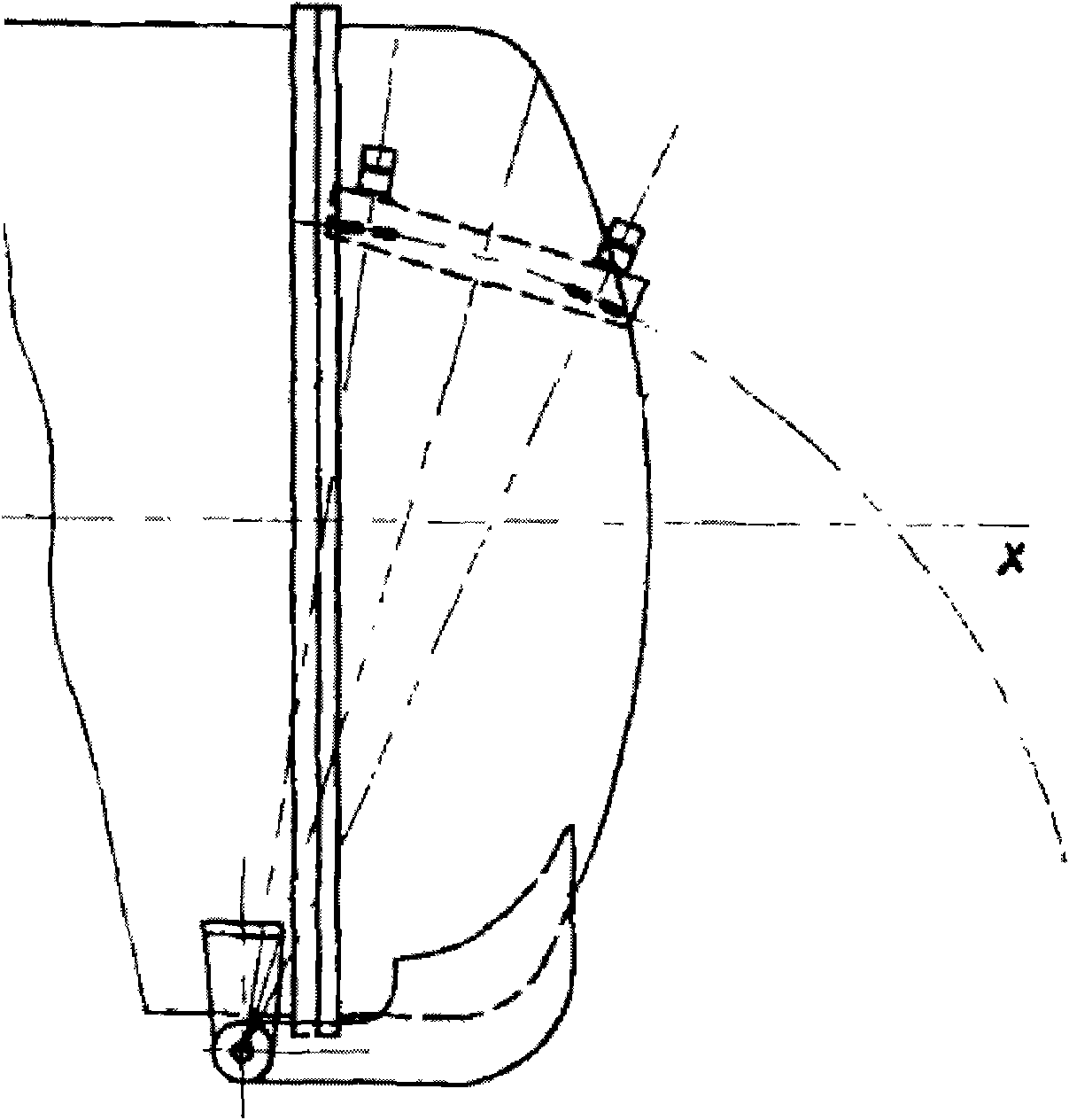

[0034] The double-cylinder hinged gate mechanism is suitable for the gates of large and medium-sized horizontal containers or cabins with a diameter > Φ4m, such as image 3 As shown, the mechanism mainly includes a hinge mechanism installed on one side of the container or cabin, a remote load-bearing unit installed at the bottom of the door on the other side, and a door tightener.

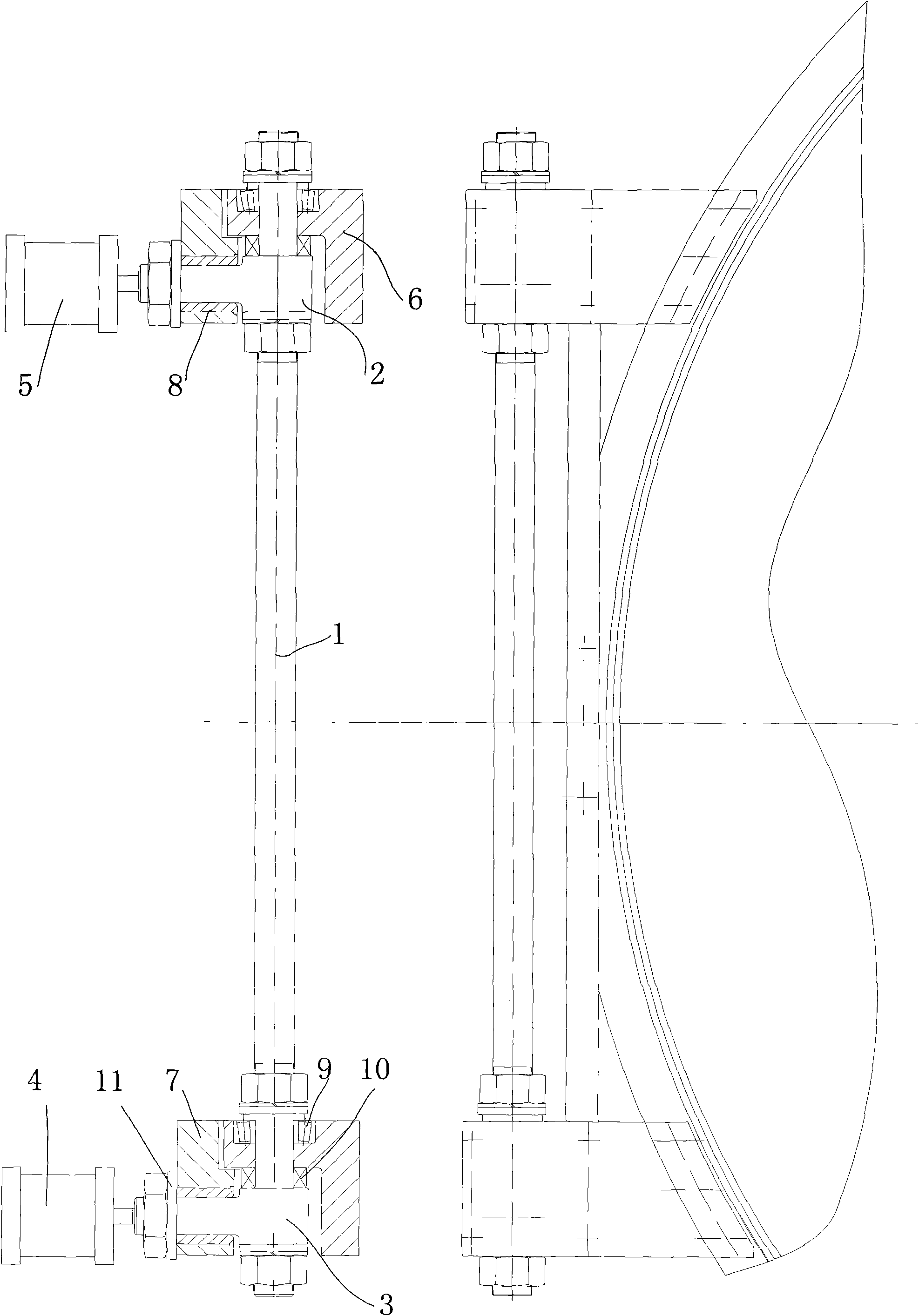

[0035] The gate can rotate around the hinge shaft (1) of the hinge mechanism. Due to the heavy weight of the gate, the hinge of the gate is far away from the center of gravity of the gate, which results in more complicated forces on the hinge mechanism. Bearing (9) and thrust bearing (10) form, and radial bearing bears radial force, and thrust bearing bears axial force. The upper hinge connecting rod (2) is connected with a tension cylinder (5), and the lower hinge connecting rod (3) is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com