Bearing with eccentric combination of rolling needles and deep groove balls

A deep-groove ball and needle roller technology, which is applied to shafts and bearings, rolling contact bearings, and rotational motion bearings, can solve the problems of difficult to achieve high-precision eccentric range and high processing difficulty, and achieve a wide range of applications and low manufacturing costs. Inexpensive, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

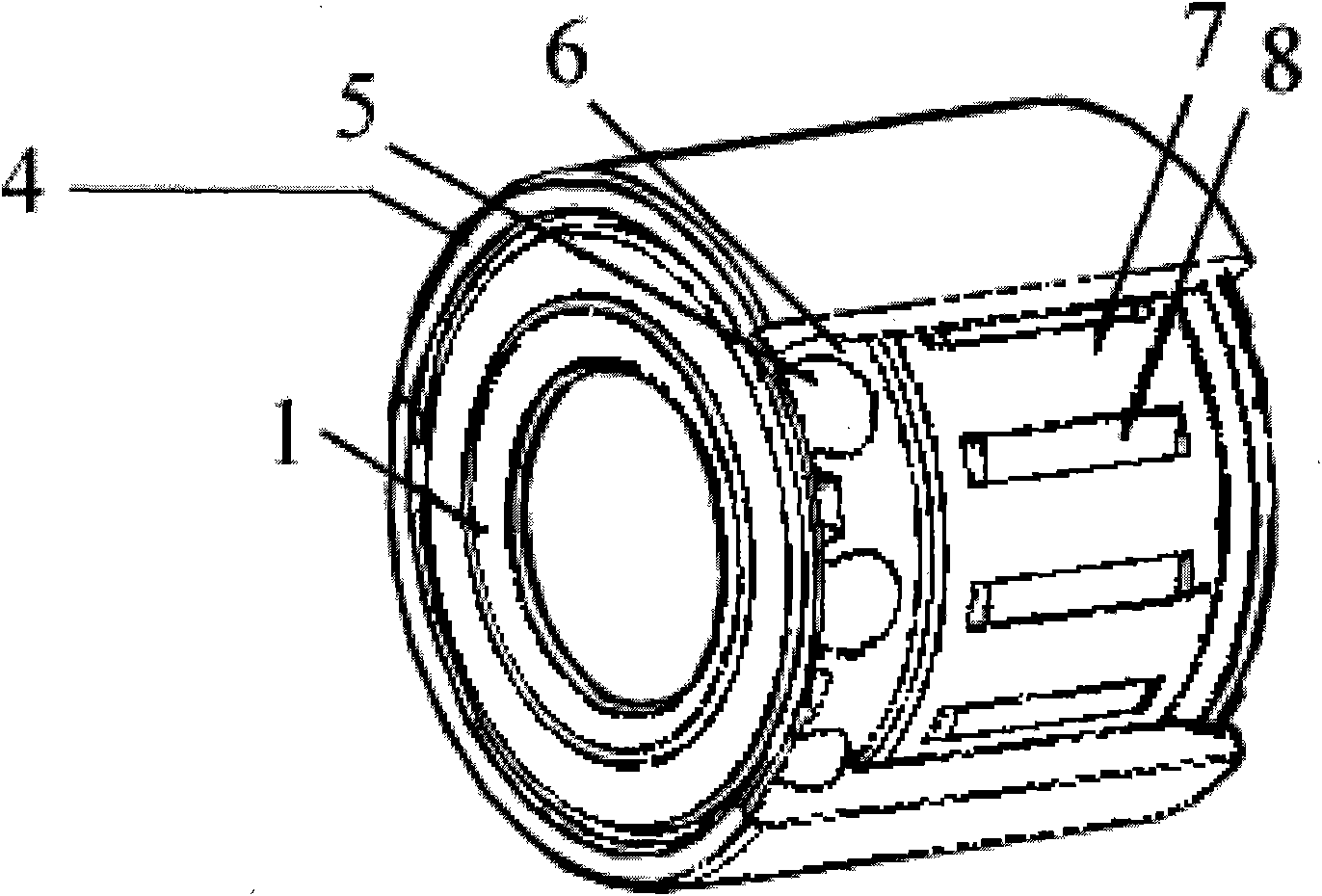

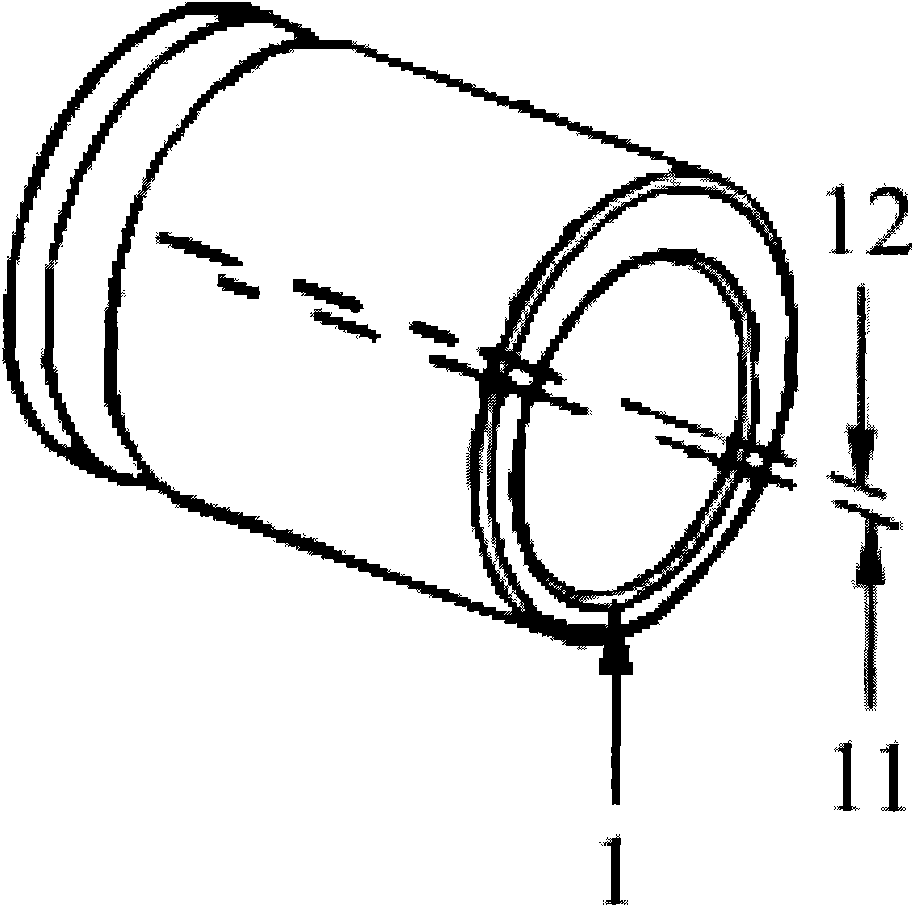

[0016] Such as figure 1 As shown, an eccentric combination bearing of needle roller and deep groove ball includes an inner ring 1, an outer ring 4, balls 5, a solid cage 6, a needle cage 7, and a needle 8. The specific structure is: the balls 5 are uniform Embedded on the outer circumference of the solid cage 6, the needle roller 8 is evenly embedded on the outer circumference of the needle roller cage 7, the solid cage 6 and the needle roller cage 7 are connected in series front and back, the solid cage 6 and the needle roller cage The inner circle hole of 7 is inserted with the inner ring 1, and the outer circumference of the solid cage 6 and the needle roller cage 7 is covered with the outer ring 4; the eccentric structure of the inner ring 1 is as follows: figure 2 As shown, the central axis 12 of the outer circle of the inner ring 1 and the central axis 11 of the inner hole are parallel to each other but not on the same straight line, and the central axis of the outer ci...

Embodiment 2

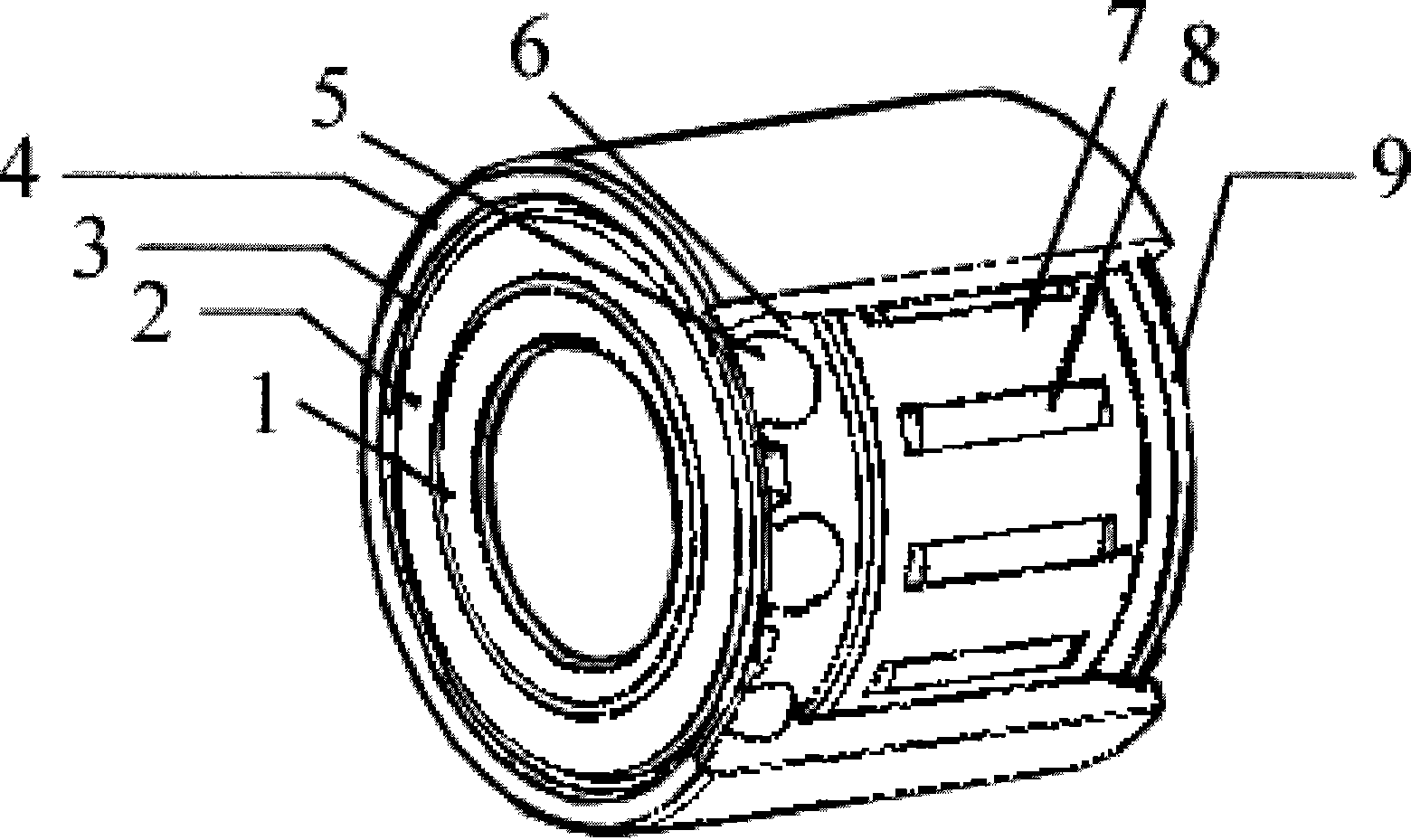

[0018] In order to make the structure of the present invention more stable and reliable, as image 3 As shown, the end face of the solid cage 6 that is not connected in series with the needle cage 7 is covered with a dust cover 2 and a tight ring 3, and the end face of the needle cage 7 that is not connected in series with the solid cage 6 is covered with a stopper Cover 9 and tight ring 3, other structures are all the same with embodiment 1. Such as Figure 4 As shown, the assembly of this embodiment is completed.

[0019] When in use, the solid cage 6 embedded with the ball 5 and inserted into the inner ring 4, that is, the ball bearing part, is used for axial positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com