Zero-backpressure electronically-controlled diesel injector driven by magnetostrictive component

A diesel fuel injector and magnetostrictive technology, applied in engine components, machines/engines, fuel injection devices, etc., can solve problems such as difficulty in responding to injection frequency, and achieve the effects of improved technical indicators, scientific structure, and convenient processing and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

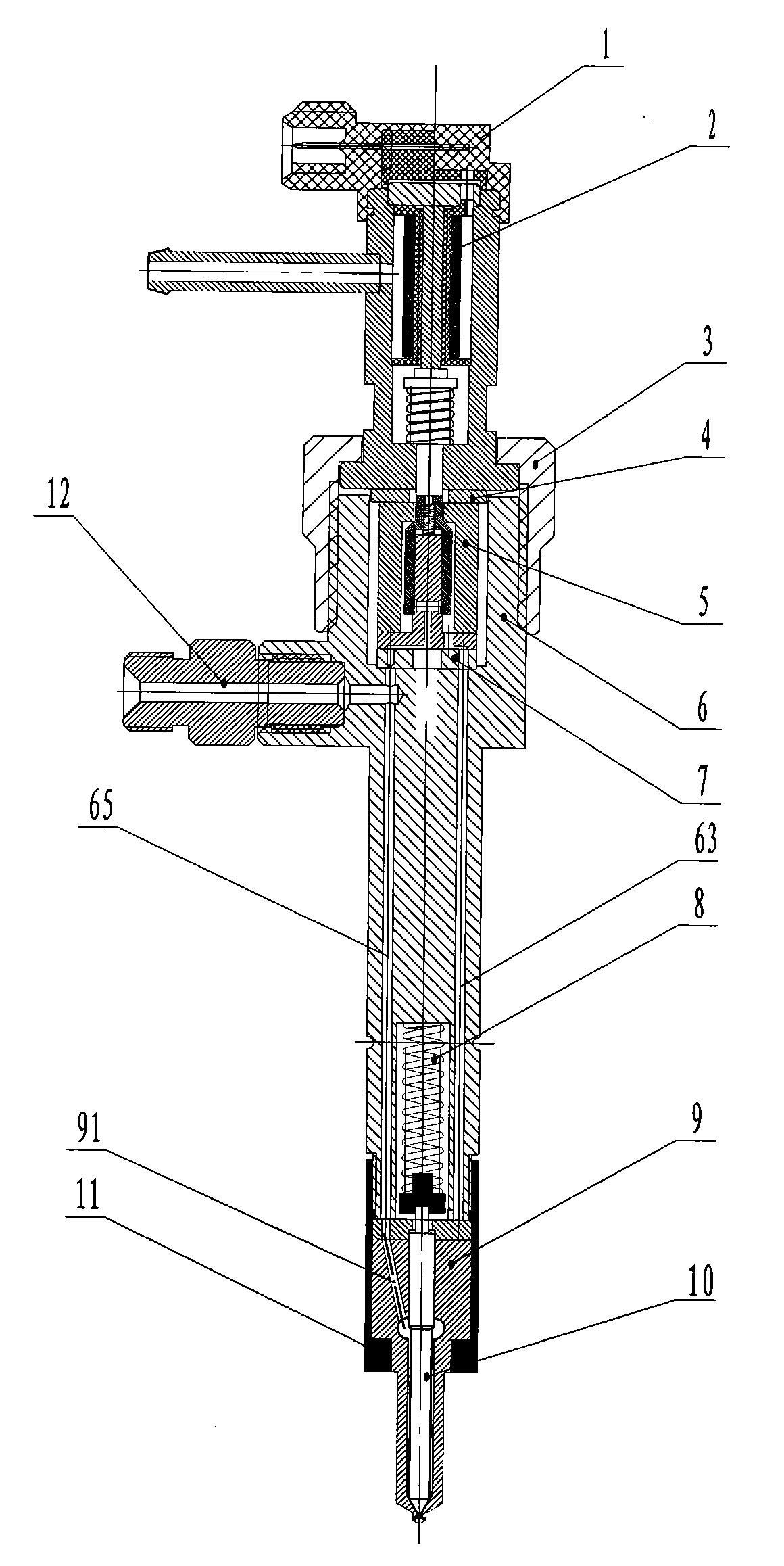

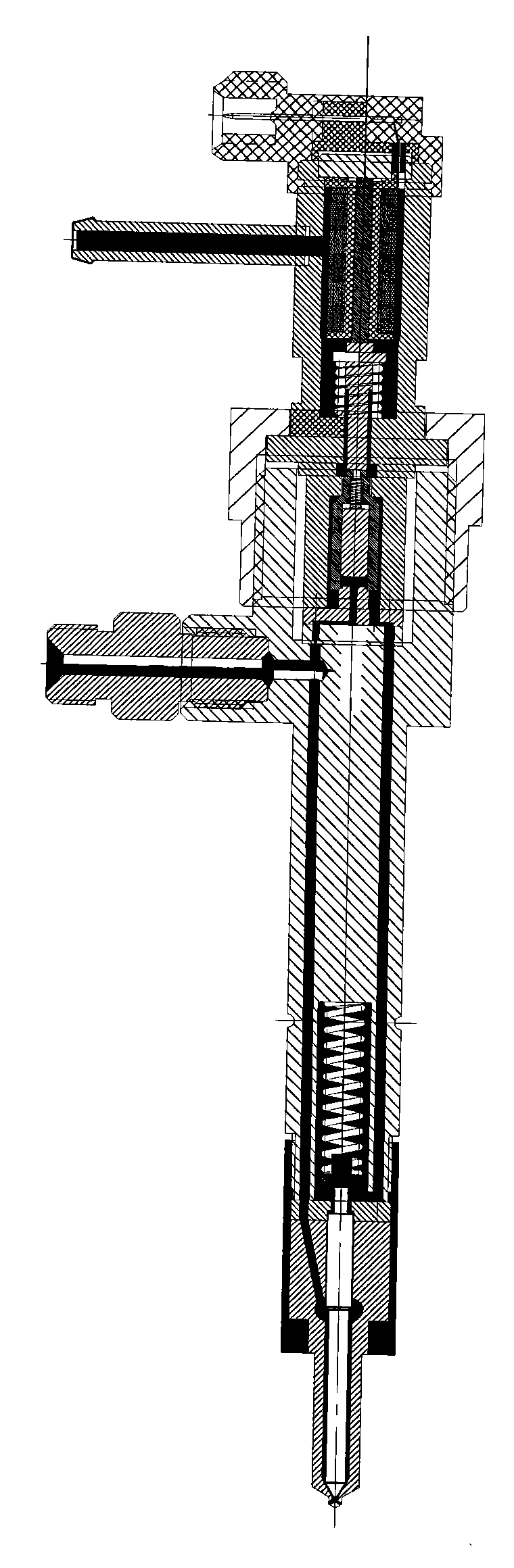

[0038] A non-backpressure electronically controlled diesel fuel injector driven by a magnetostrictive element, comprising a fuel injector housing 6 with an oil inlet channel and an oil return channel, a nut sleeve 11, a magnetostrictive driver 2, a lock nut 3, Adjust gasket 4, non-back pressure two-position three-way valve 5, transition block 7, pressure spring 8, fuel injector assembly 9 and valve needle 10, and install transition blocks in sequence along the axial direction in the fuel injector housing 6 7. Two-position three-way valve without back pressure 5. Adjusting gasket 4. Lock nut 3. Magnetostrictive driver 2. Install pressure spring 8, fuel injector assembly 10, and fuel injector in sequence in nut sleeve 11. The upper and lower end surfaces of the housing 6, the transition block 7, the two-position three-way valve 5 without back pressure, the two end surfaces of the adjusting gasket 4, and the lower end surface of the magnetostrictive driver 2 are all high flatness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com