Method for negative-pressure unloading of sulfuric acid tank cars of train

A technology of negative pressure acid unloading station and tanker, which is applied in the direction of special distribution devices, etc. It can solve the problems of difficult operation, low efficiency, and high safety risk, and achieve the effects of small safety and environmental risks, easy operation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Taking the train sulfuric acid tank car acid unloading station of Wengfu (Group) Co., Ltd. as an example, with the method of the present invention, the negative pressure acid unloading station of train sulfuric acid tank car has been designed and built, and this acid unloading station can unload the imported acid on average every year. The concentrated sulfuric acid is about 600,000 tons.

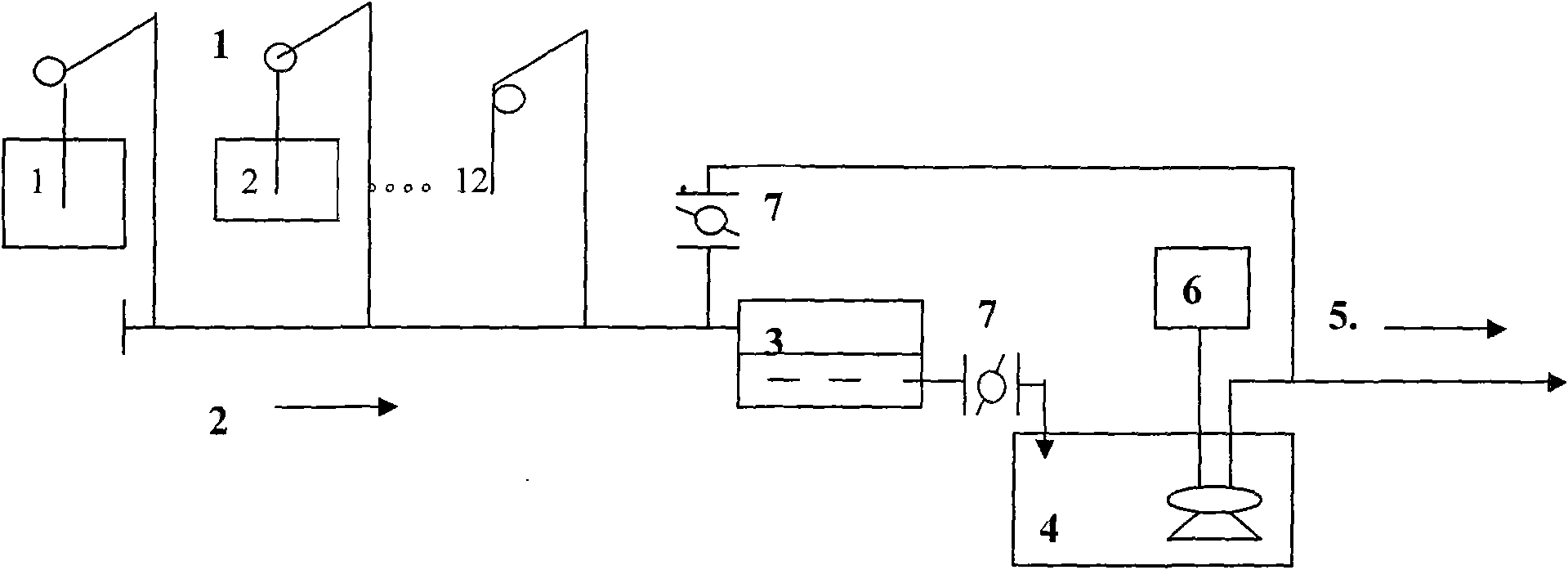

[0013] 1. Process flow

[0014] This set of negative pressure unloading device for train sulfuric acid tanker on the negative pressure acid unloading station is composed of unloading crane pipe, unloaded acid to pump tank pipeline, vacuum tank, pump tank, and pipeline to user storage tank;

[0015] 2. Operating procedure

[0016] 1) Drag the 1-12 section sulfuric acid train tank car to the negative pressure acid unloading station, place it at the position corresponding to the unloading crane tube and fix it.

[0017] 2) Close the outlet valve of the vacuum tank, start the pump, ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com