Direct backlight module

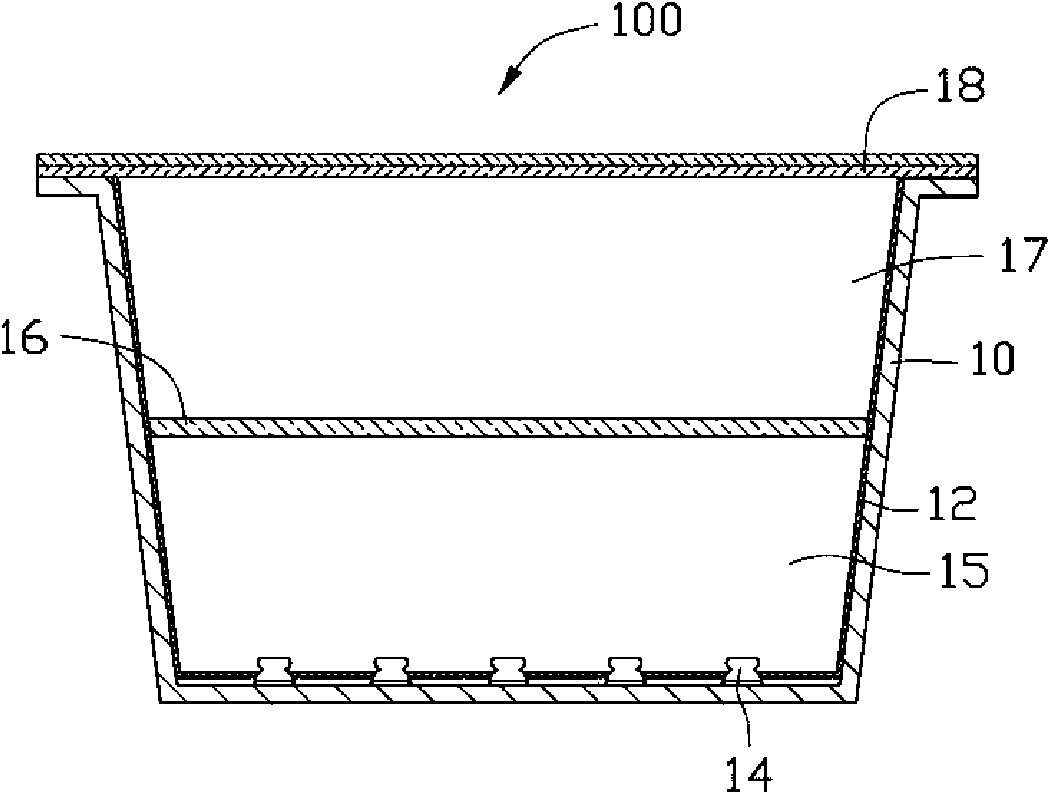

A backlight module, direct type technology, applied in the field of direct type backlight modules, can solve the problems of increasing power consumption, the thickness of the direct type backlight module 100 is large, and it is difficult to meet the thin design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The direct-lit backlight module of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

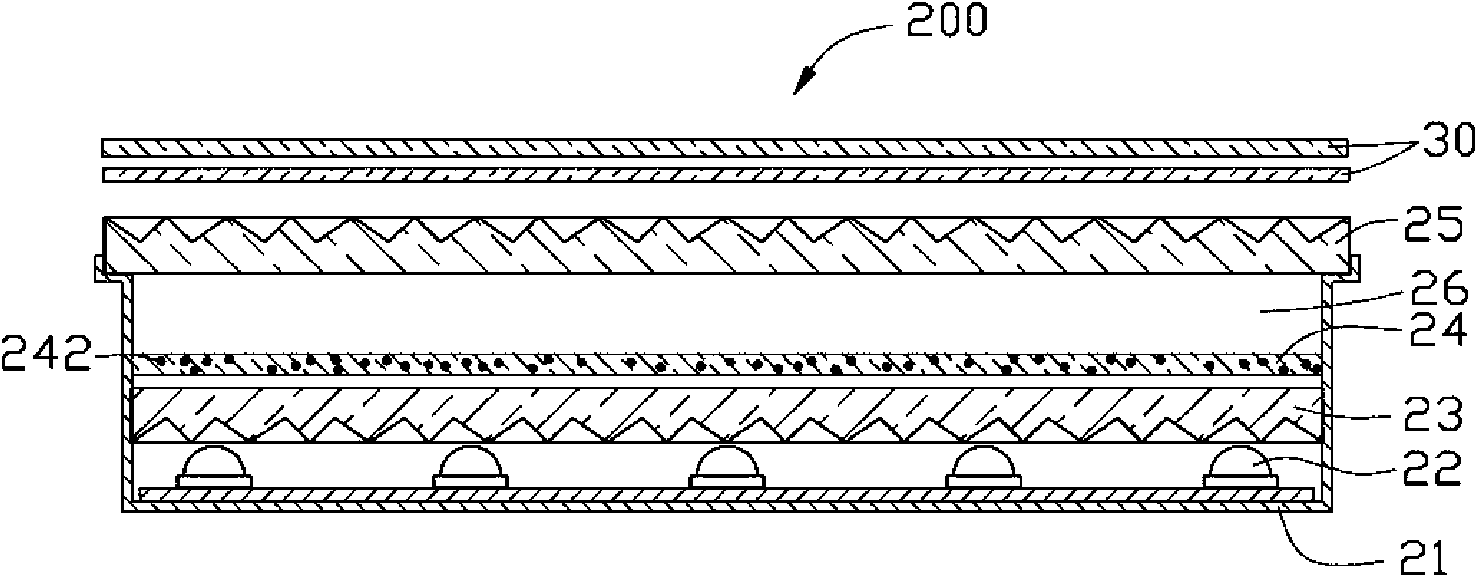

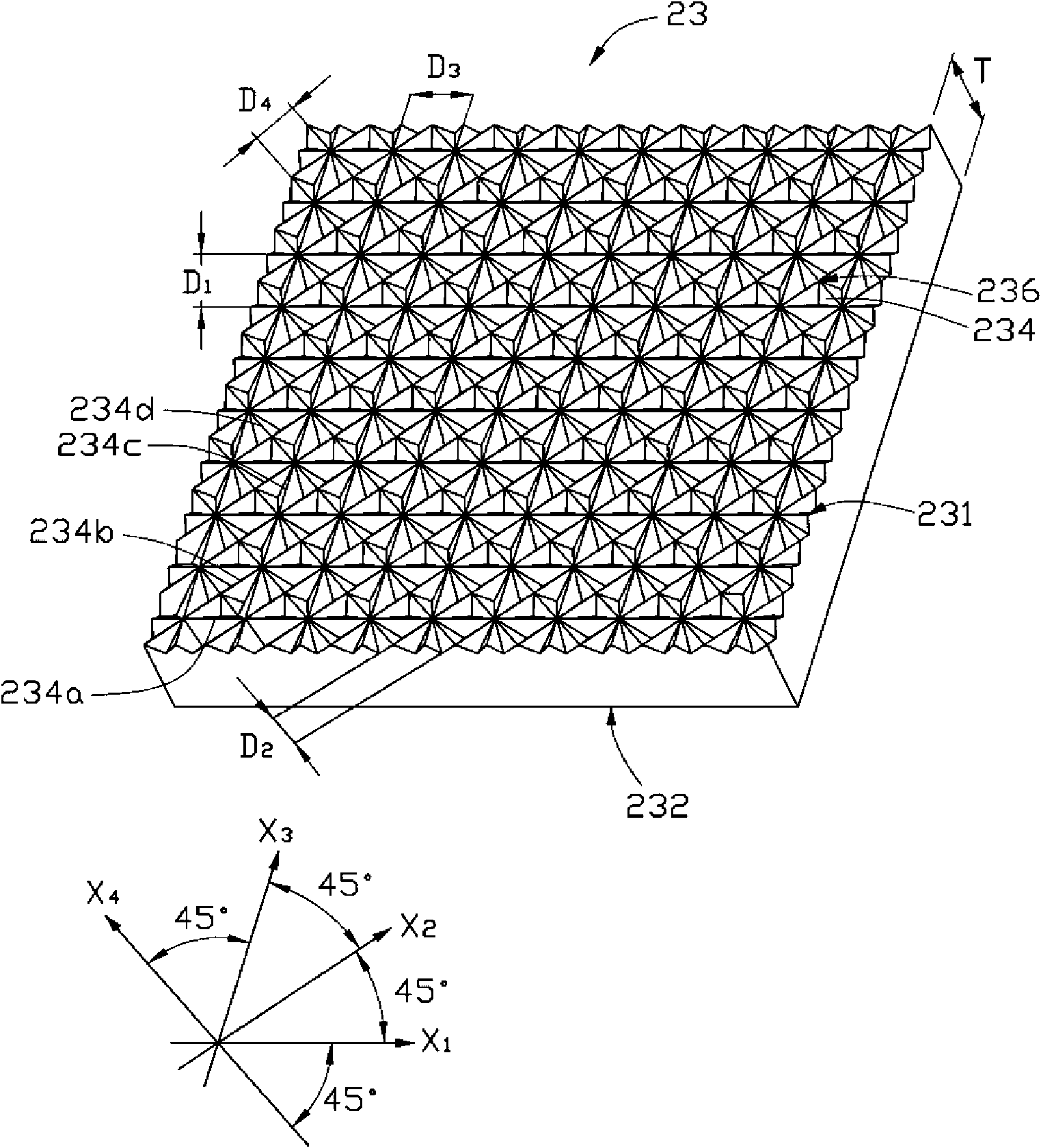

[0017] See figure 2 The direct type backlight module 200 according to Embodiment 1 of the present invention includes a frame 21 , a plurality of LEDs 22 disposed on the bottom plate of the frame 21 , a diffusion plate 24 , a first optical plate 25 and a second optical plate 23 . The first optical plate 25 covers the open end of the frame 21 . The diffusion plate 24 is disposed above the LEDs 22 . The second optical plate 23 is disposed between the LEDs 22 and the diffusion plate 24 . The first optical plate 25 and the diffusion plate 24 are separated by a certain distance, thereby forming a diffusion space 26 .

[0018] The frame 21 can be made of metal or plastic with high reflectivity on the surface, or a coating with high reflectivity can be coated on the inner wall of the frame 21 so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com