an engine cooling system

A technology for engine cooling and engine block, which is applied in the direction of engine cooling, engine components, machines/engines, etc., can solve engine cooling and other problems, and achieve the effects of emission optimization, fuel economy improvement, and cooling effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

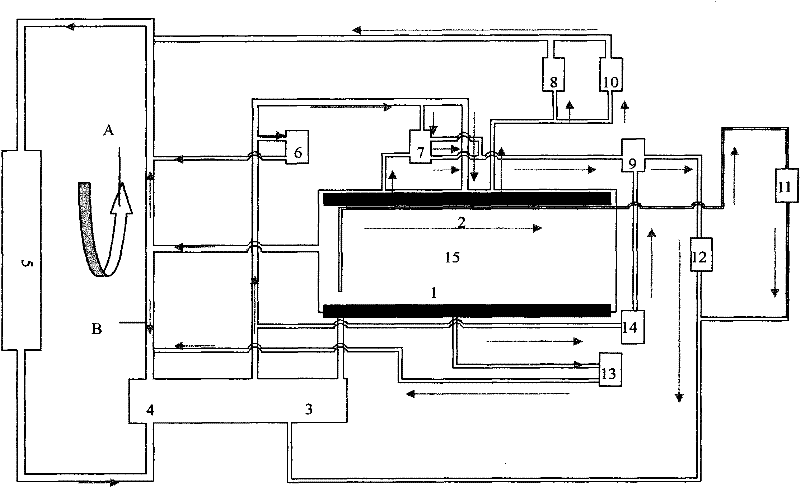

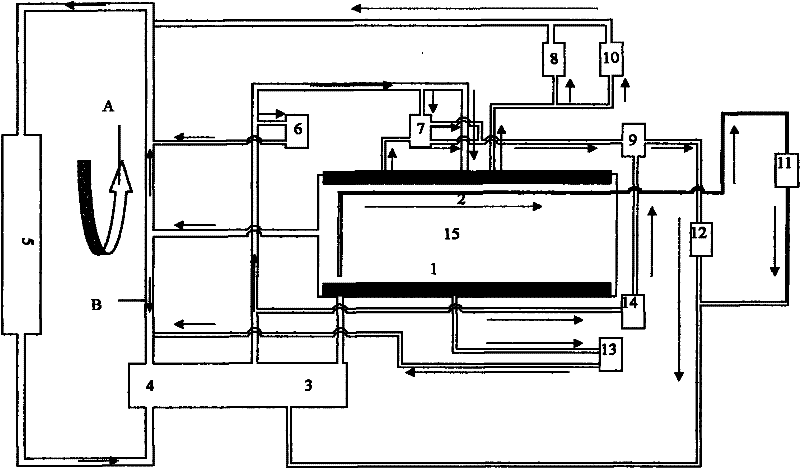

[0019] The present invention will be specifically described below in conjunction with the accompanying drawings.

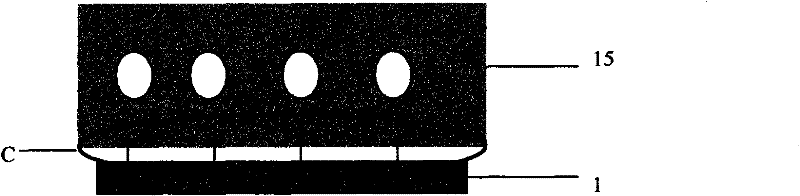

[0020] Such as figure 1 As shown, the thermostat 4 of this cooling system is installed in the inlet type, and the cooling water passes through the water pump 3. Using the centrifugal force, the water pump 3 pumps the water into the two distribution pipes 1 and 2 installed at the lower part of the cylinder, as shown in figure 1 As shown, the distribution pipes 1 and 2 have multiple passages, and each passage corresponds to a cylinder. Cooling water enters the cylinder body through each passage to cool the engine, and then the coolant enters the cylinder head through the cylinder body to cool the engine cylinder head. Then the coolant returns to the water collector through the cylinder head, finally returns to the thermostat 4, and finally returns to the water pump 3, thereby realizing the circulation of the cooling system.

[0021] The water that the water pump 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com