Oil purifying system

An oil purification and oil liquid technology, applied in the field of oil purification system, can solve the problems of difficult to keep the oil system clean continuously for a long time, unable to remove moisture and impurities at the same time, troublesome operation and maintenance, etc., to achieve long life, convenient replacement and obvious effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

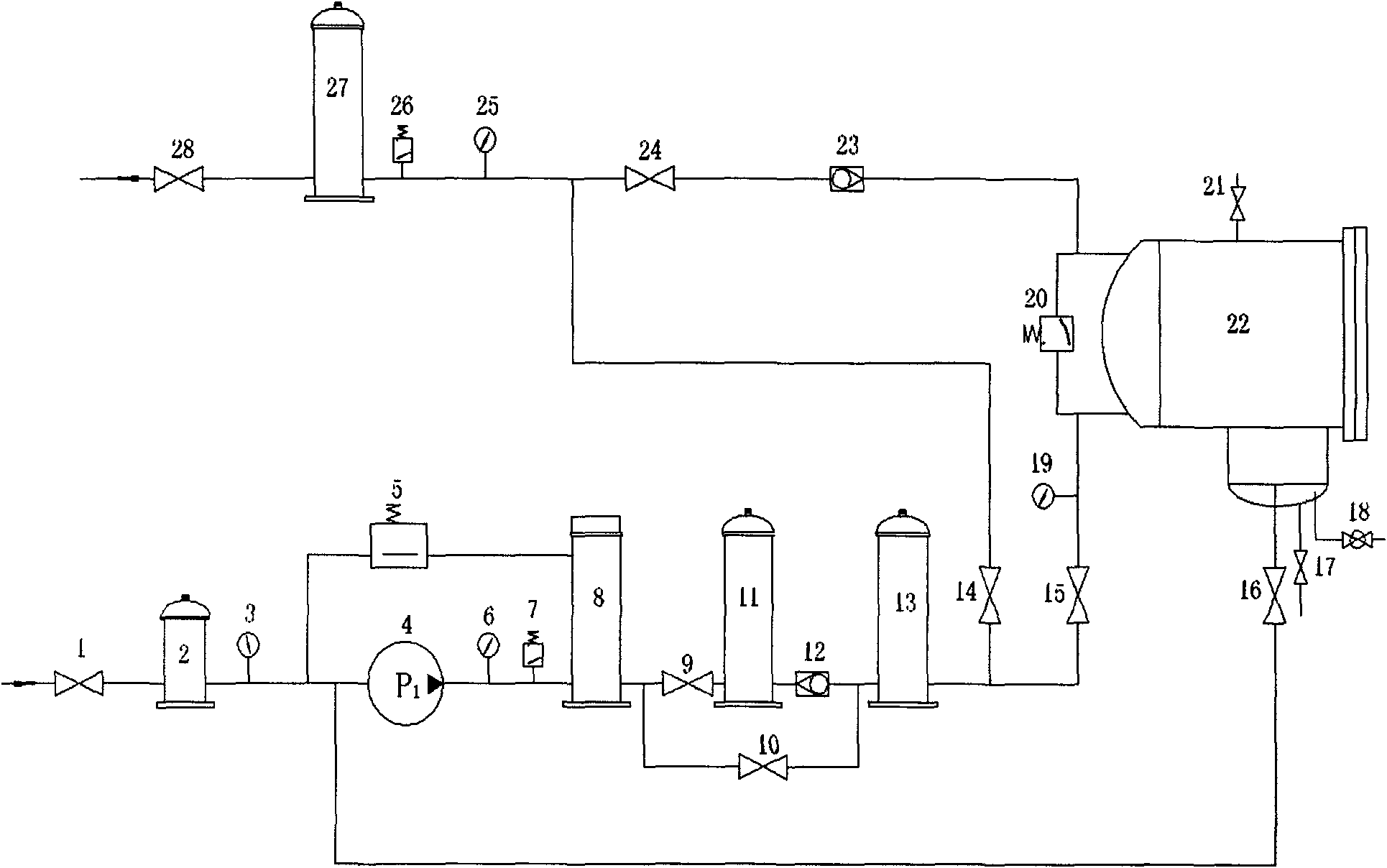

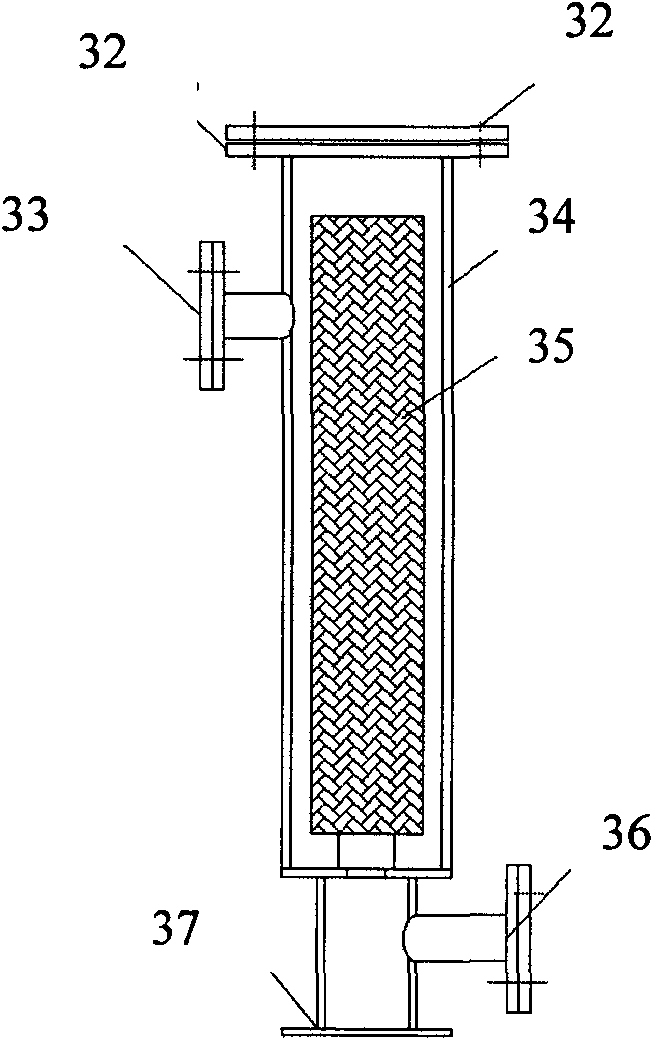

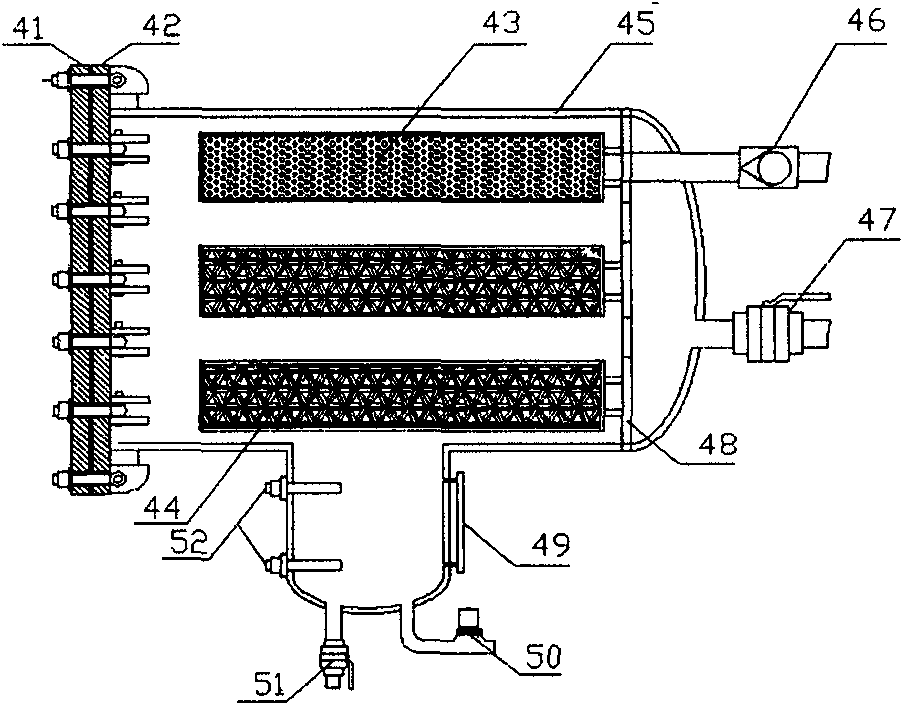

[0032] Such as figure 1 , the oil purification system includes inlet valve 1 (to control oil inlet), inlet filter 2 (to filter out large particles of mechanical impurities), vacuum pressure gauge 3 (to test the vacuum degree at the inlet of the oil pump), oil delivery pump 4 (to input oil), super Pressure protection 5 (when the set pressure value is exceeded, an alarm will be automatically issued for bypass work), the first pressure gauge 6 (to test the outlet pressure value of the oil pump), pressure controller 7 (when the set pressure value is exceeded, the protection equipment ), heater 8 (to heat the oil), the first switch valve 9 (to control the oil circuit of the demulsification device), the second switch valve 10 (to enter the fine filter directly), and the filter element type demulsification device 11 (to control the emulsifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com