Discharge lamp and method for producing a discharge lamp

A technology for discharge lamps and high-pressure discharge lamps is applied in the field of manufacturing such discharge lamps and high-pressure discharge lamps, which can solve the problems of time-consuming and second-best, and achieve the effect of reducing defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

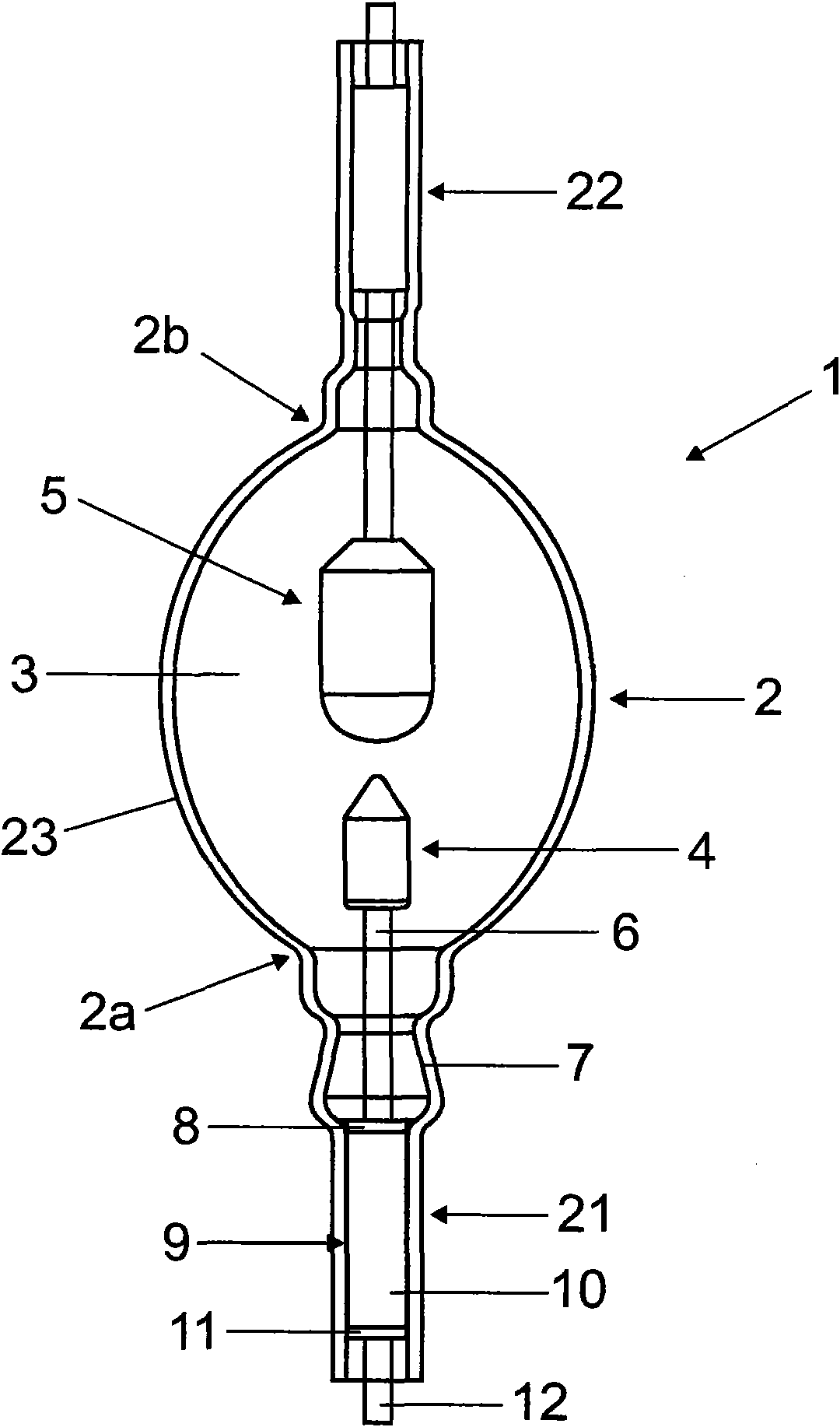

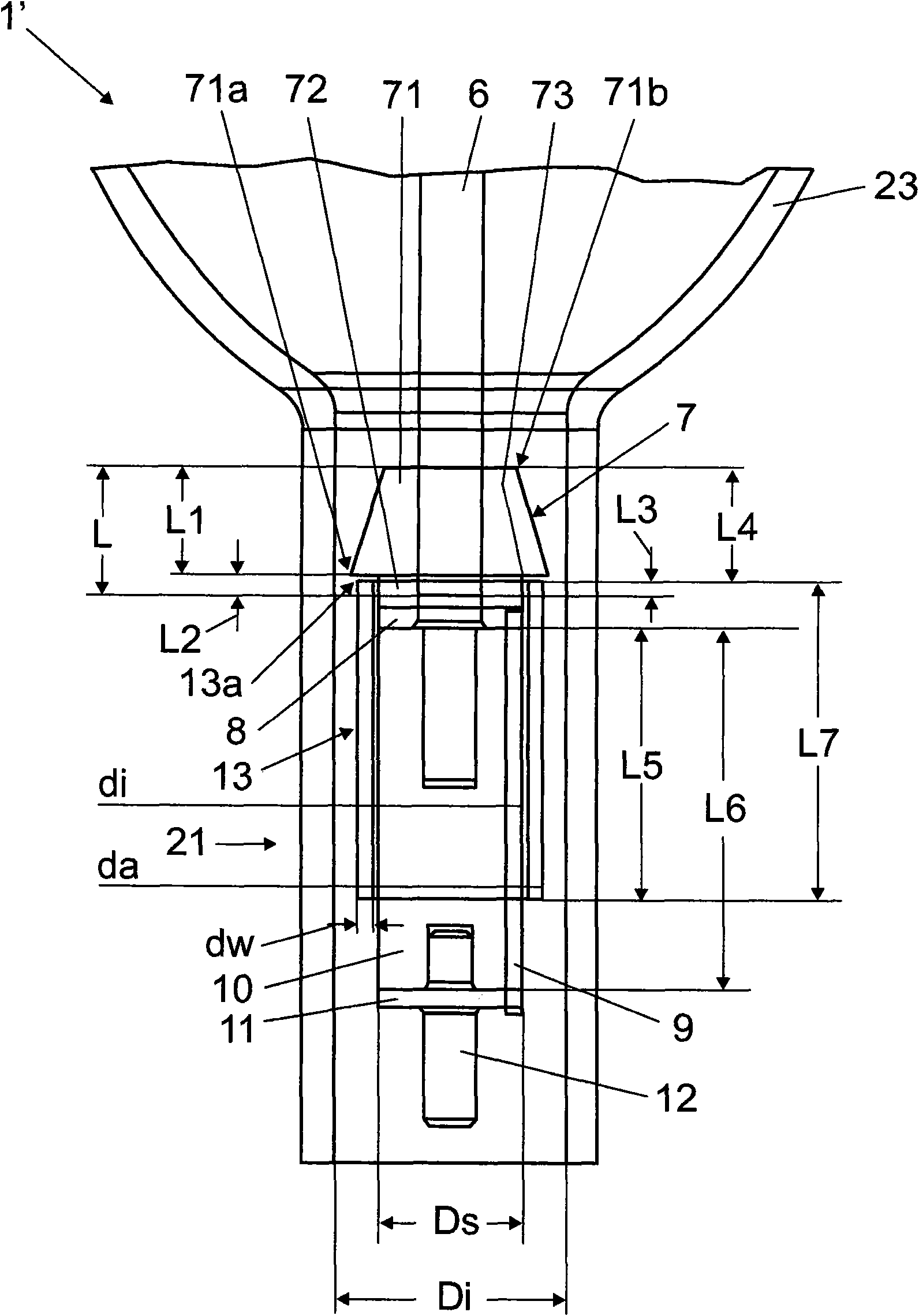

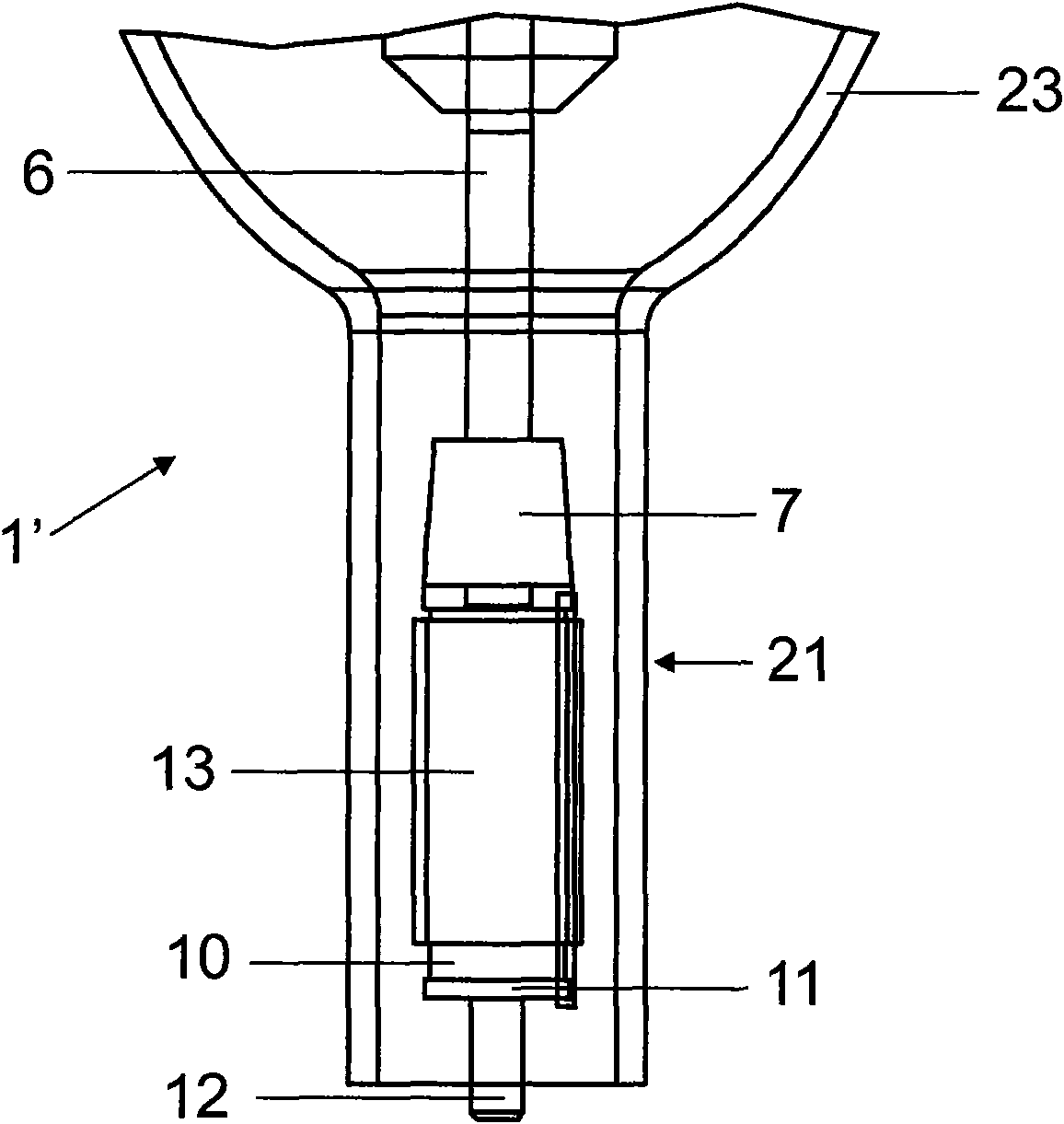

[0039] exist figure 2 A schematic cross-sectional view of a partial region of a discharge lamp 1' constructed as a high-pressure discharge lamp according to the invention is shown in . In principle, this discharge lamp 1' is realized according to the configuration in Fig. 1 . However, the important difference is that the discharge lamp has a base in the region of the bulb neck 21 figure 2 configuration. Similarly, in figure 2 The configuration shown in the region of the bulb neck 21 is also realized in the region of the bulb neck 22 . The configuration on bulb neck 21 is illustrated in detail by way of example.

[0040] In the stem tube of the bulb neck 21 (which transitions into the middle part of the discharge device 2 in the region 2a or in the ellipsoidally shaped partial region 23), a holding rod 6, made of quartz glass as a support, is partially arranged. The supporting part of the small tube 7 , the disc 8 following it and the carrying part following the disc 8 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com