Flow sensor

A flow sensor and sensor chip technology, which is applied in the field of flow sensors, can solve problems such as difficult airtight connections, and achieve the effect of easy sealing and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Next, in order to describe the present invention in more detail, the best mode for carrying out the present invention will be described with reference to the accompanying drawings.

[0059] Embodiment 1

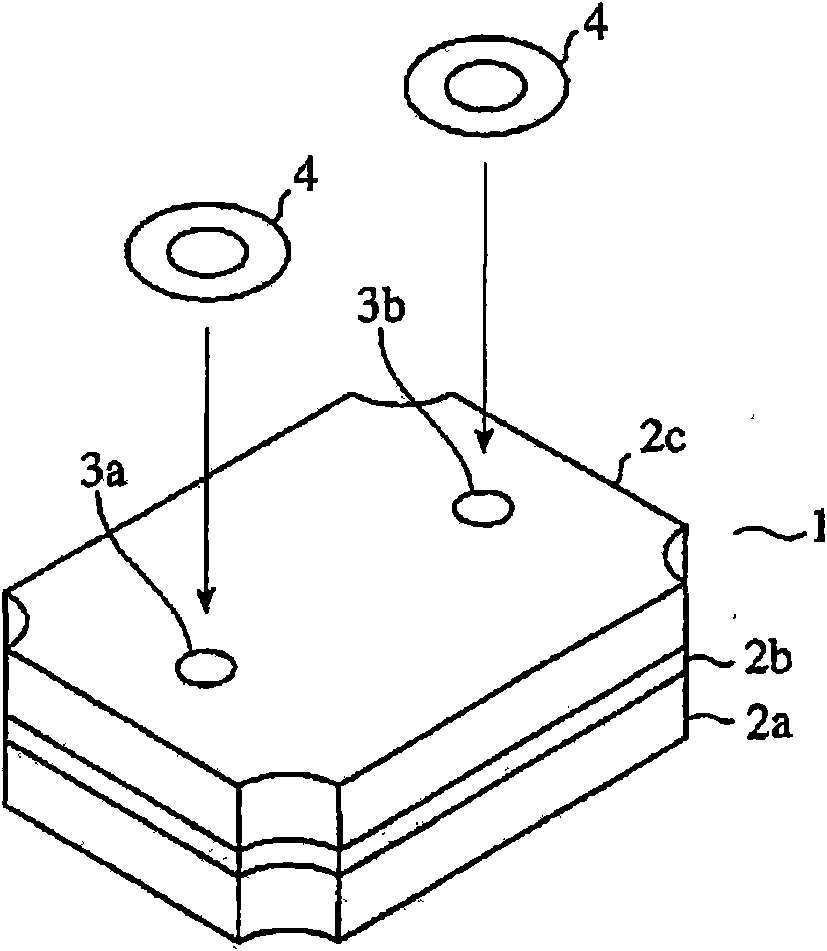

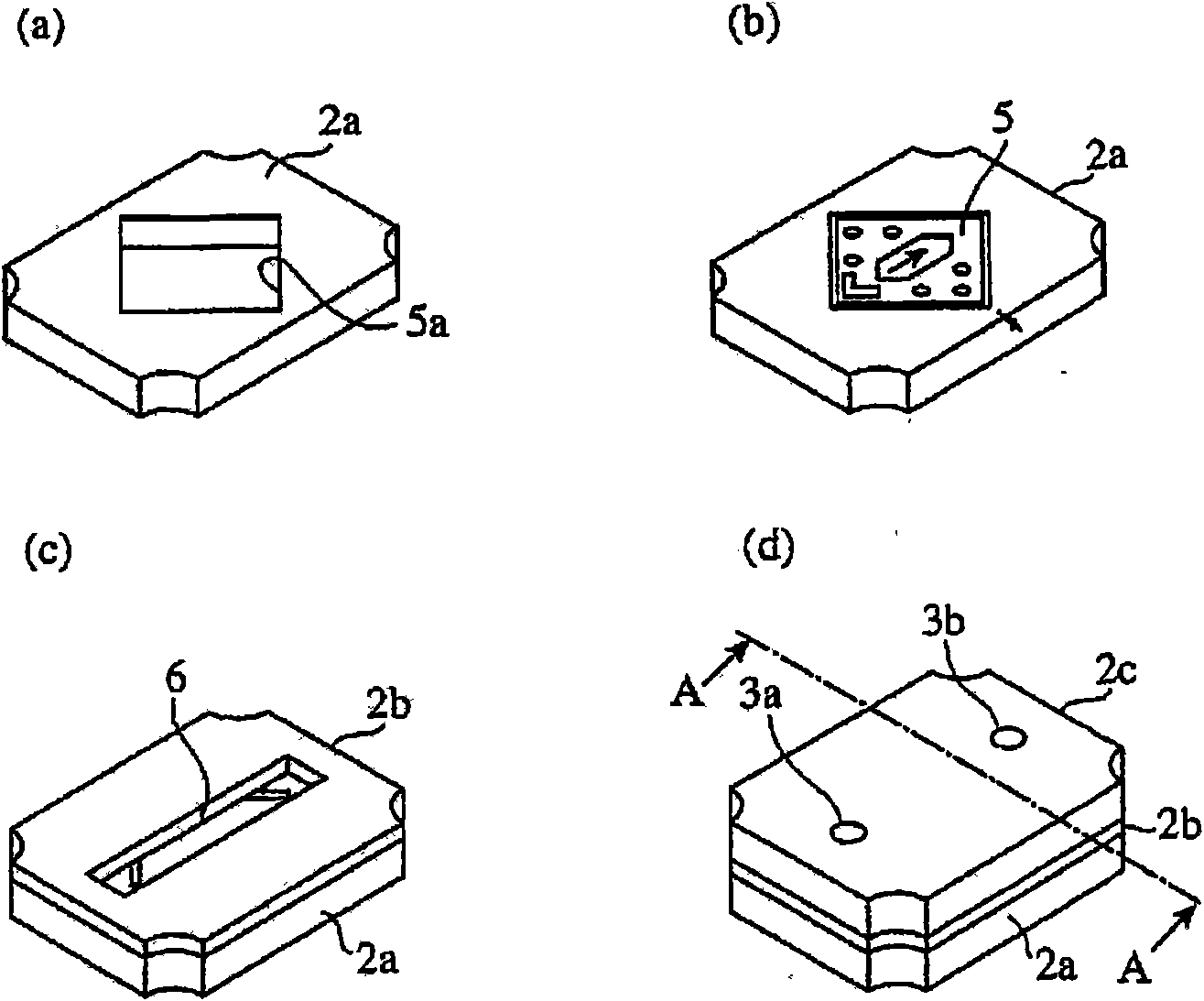

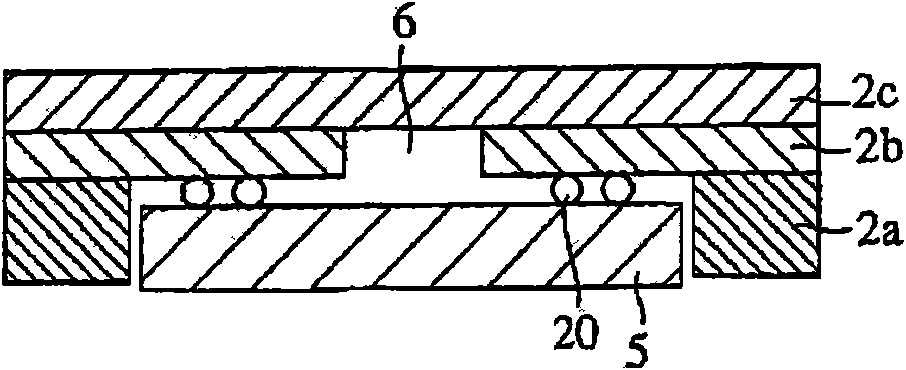

[0060] figure 1 It is a perspective view showing the sensor according to Embodiment 1 of the present invention, and shows a flow sensor configured by accommodating a sensor chip in a package formed by bonding three substrates. Such as figure 1 As shown, in the flow sensor 1 of Embodiment 1, the sensor chip is mounted inside a rectangular package formed by firing and joining ceramic substrates 2a, 2b, and 2c, and the same flat end surface (substrate 2c surface) of the package On the upper side, both the inlet 3a and the outlet 3b of the flow path in the module through which the gas to be measured flows are provided.

[0061] In addition, the substrates 2a to 2c constituting the components of the flow sensor 1 are flat substrates that do not have concavo-convex port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com