Anti-rotating insulating support and anti-rotating method thereof

A technology of insulating support and anti-rotation, applied in the direction of fixed/insulated contact components, etc., to achieve the effects of good electrical transmission performance, enhanced fastness, and good fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

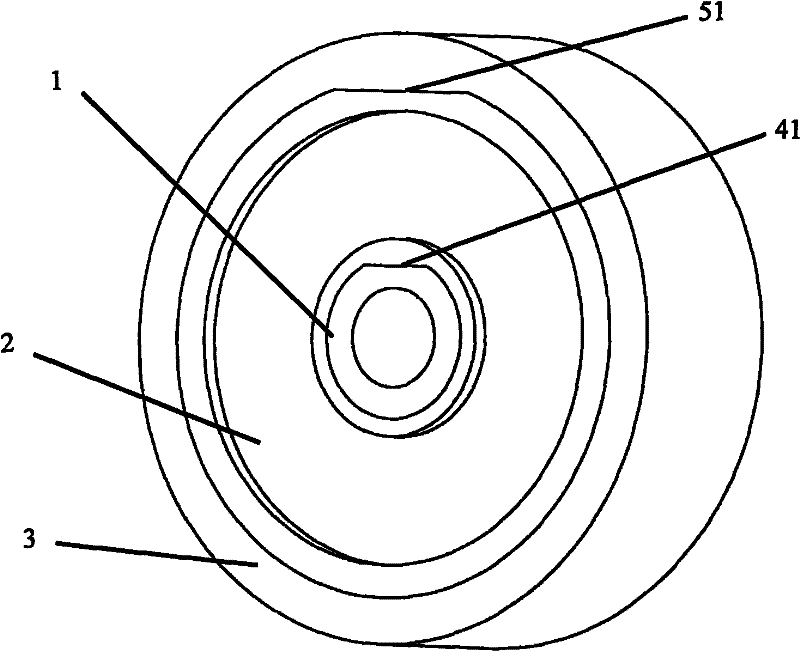

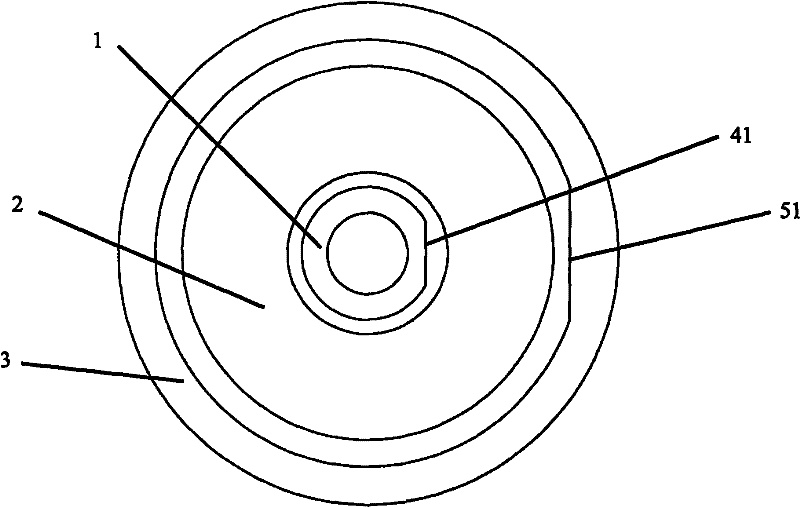

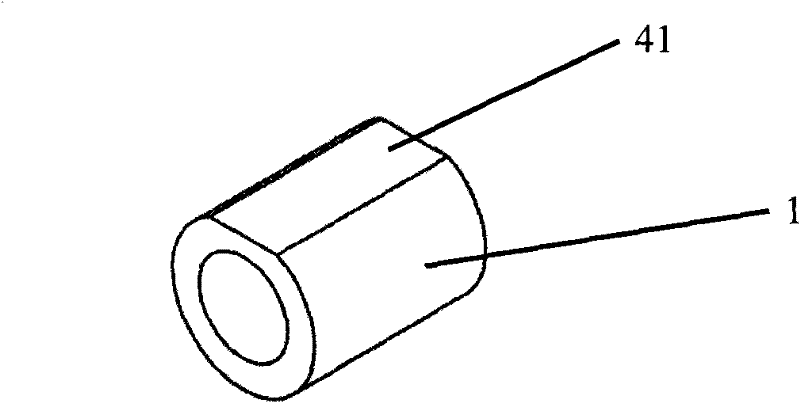

[0028] figure 1 It is a structural schematic diagram of a preferred embodiment of the anti-rotation insulating support of the present invention, figure 2 It is a schematic diagram of its front structure. The anti-rotation insulating support includes a metal inner sleeve 1, an intermediate medium 2, and a metal outer ring 3 connected from the inside to the outside. The inner ring of the cross section of the metal inner sleeve 1 is circular and cooperates with the central conductor , the outer surface of the metal inner sleeve 1 has a cut inner sleeve first platform 41 along the tube length direction, the inner sleeve first platform 41 is parallel to the central axis of the metal inner sleeve 1 and penetrates both horizontally and vertically, and the metal inner sleeve 1 The outer ring of the cross-section is circular, and its circular angle is between 50° and 60°, which can also be seen in detail Figure 3a The schematic diagram of the three-dimensional structure of the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com