Lithium ion battery packaging film and manufacturing method thereof

A technology of lithium-ion batteries and manufacturing methods, which is applied to battery pack parts, chemical instruments and methods, circuits, etc., can solve the problems of high cost, poor compactness, and short life of lithium-ion battery packaging films, and achieve less pores and higher density Good sex and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

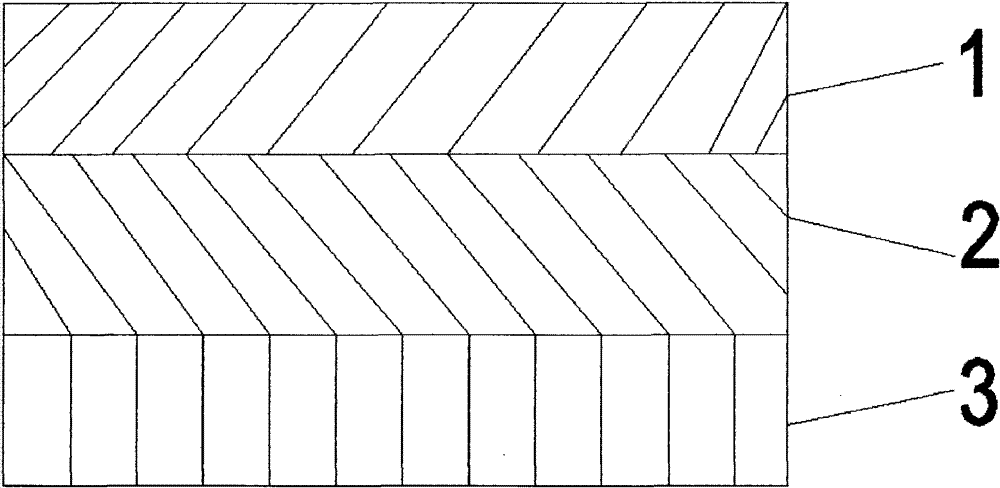

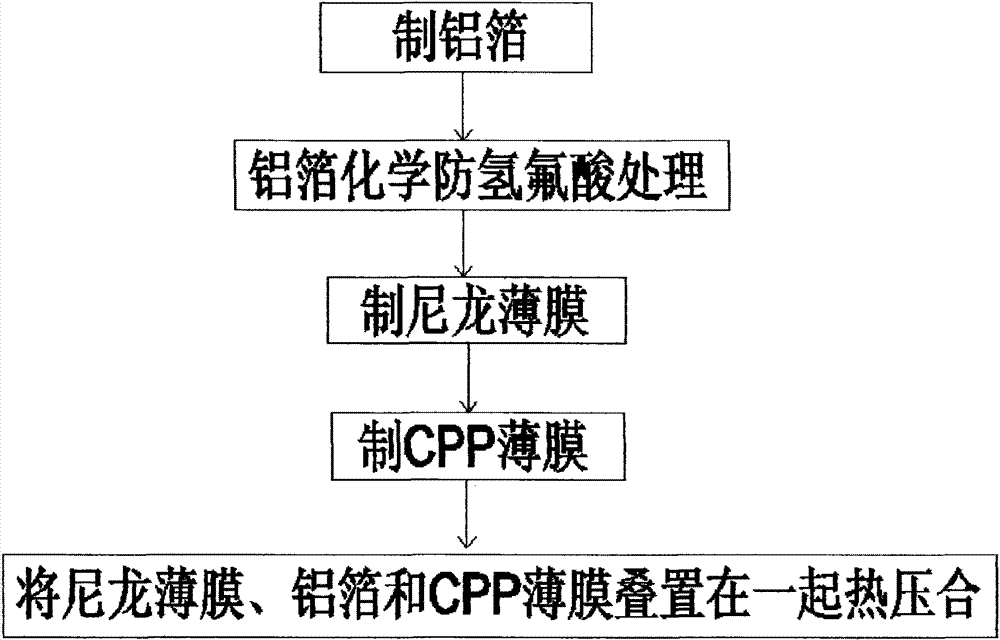

[0022] Such as figure 1 As shown, the lithium-ion battery packaging film of the first invention of the present application has a laminated laminated structure. The surface layer 1 is various types of nylon with a thickness of 0.01-0.1mm. The various types of nylon refer to nylon 6 engineering plastics, nylon 66 engineering plastics, nylon 610 engineering plastics, nylon 1010 engineering plastics, alcohol-soluble nylon, three Copolycondensation nylon (insoluble), reinforced nylon 66 engineering plastics, etc. The inner layer 2 is various types of aluminum foils with a thickness of 0.01-0.1 mm. The surface layer 3 is various types of CPP (polypropylene), the thickness of which is 0.01-0.1mm. The various types of CPP are PP, CPP or fluorinated polypropylene and other types of PP or modified PP. The lithium-ion battery packaging film does not have an adhesive layer, that is, it does not contain various hot-melt adhesives, that is to say, there is no substance corroded by the lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com