Two-stage speed-down pulverized coal burner

A pulverized coal burner and the technology of the burner are applied in the burner, the burner for burning powder fuel, the burning method, etc., and can solve the problems of low volatile content and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

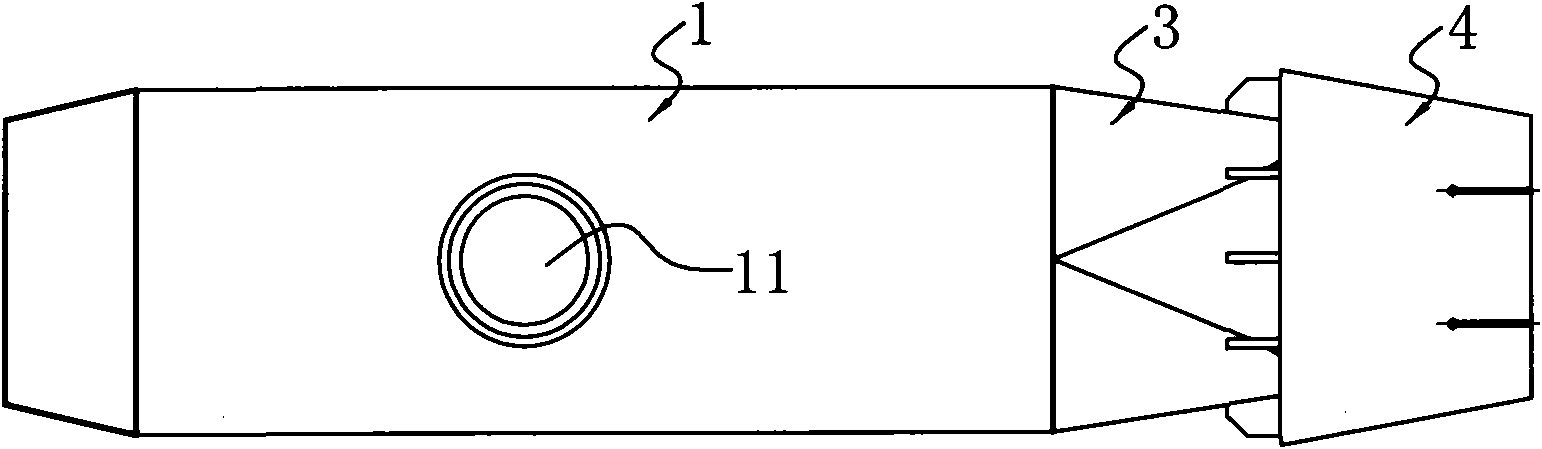

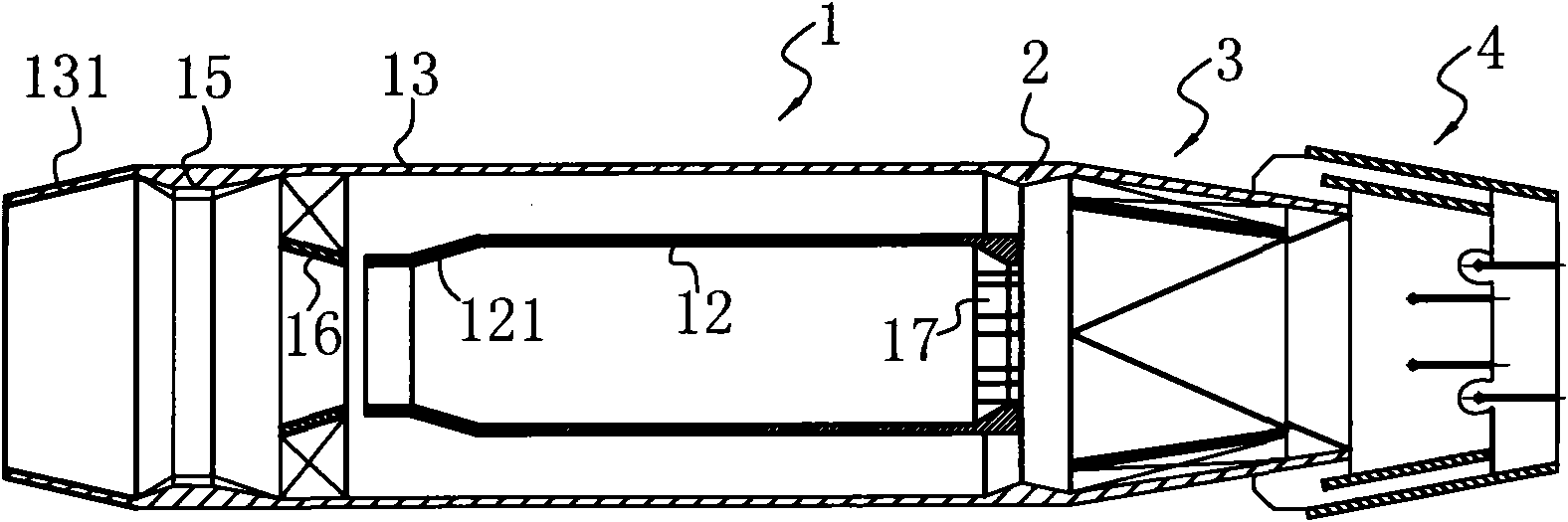

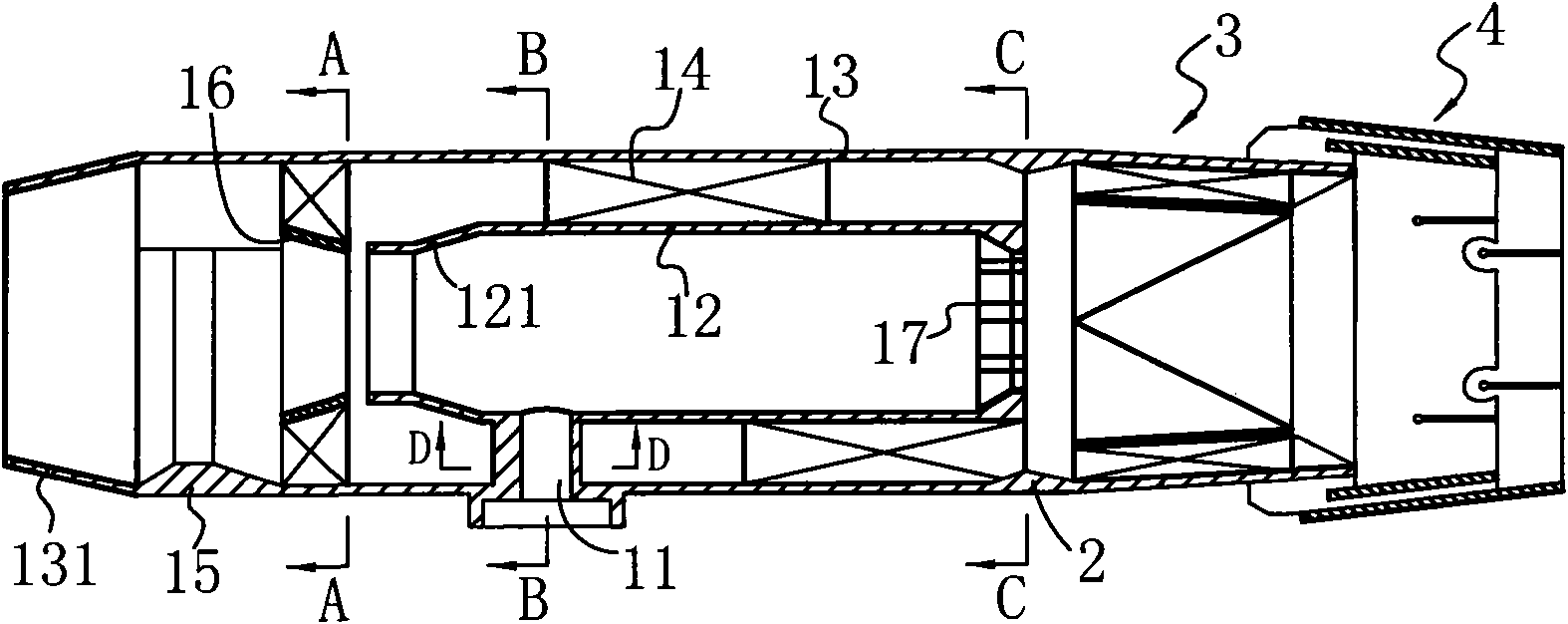

[0038] Such as Figure 1-3 As shown, the present invention provides a pulverized coal burner, which includes a reduced-speed ignition combustion chamber 1, and at least one socket 11 is provided on the axial side wall of the reduced-speed ignition combustion chamber 1. In this embodiment, it is provided There is a socket 11, and an ignition device is inserted in the socket 11 for igniting the pulverized coal passing through the reduced-speed ignition combustion chamber 1 . Wherein, the ignition device may be a micro-oil gun or a plasma gun or the like.

[0039] Since the heating energy of pulverized coal is directly proportional to the heating time under the premise that other conditions remain unchanged, the heating energy of the pulverized coal by the flame will be doubled every time the air velocity is doubled. In the present invention, its ignition combustion chamber is set as a speed-reducing ignition combustion chamber 1, that is, the speed at which pulverized coal pass...

Embodiment approach 2

[0049] In this embodiment, combined with Figure 8-10 As shown, the burner also includes a mixed combustion chamber 3 in addition to the above-mentioned reduced-speed ignition combustion chamber 1, and the mixed combustion chamber 3 is connected to the pulverized coal outlet end (rear end) of the reduced-speed ignition combustion chamber 1. The mixed combustion chamber 3 is provided with a thick-lean separation pipe 31 axially in the center, the diameter of the rear end of the thick-lean separation pipe 31 is larger than the diameter of the deceleration pipe 12, and the thick-lean separation pipe 31 and the outer wall of the mixed combustion chamber 3 pass through at least one rib 32 connections. The pulverized coal that comes out from the deceleration pipe 12 is sprayed into the thick-lean separation pipe 31 of the mixed combustion chamber 3, and the pulverized coal in the thick-lean separation pipe 31 is ignited. A part also enters the thick-thin separation pipe 31, and the...

Embodiment approach 3

[0053] combine Figure 8-10 As shown, the burner can also include an oxygen supply enhanced combustion chamber 4, which is connected to the tail end of the mixing combustion chamber 3, so that all the pulverized coal in the mixing combustion chamber 3 enters the oxygen supply enhanced combustion chamber 4. The high-temperature flame in the oxygen supply enhanced combustion chamber 4 mixes with the dilute-phase pulverized coal and ignites the dilute-phase pulverized coal to realize the complete combustion of the pulverized coal. The volatile matter in the first two combustion chambers 1 and 3 is basically burnt out. In order to improve the burnout rate of loose charcoal, the measure of enhanced combustion with oxygen supplementation in advance is adopted. The oxygen supplementation in advance meets the oxygen amount required for pulverized coal combustion in time. The enthalpy of the oxygen supply enhanced combustion chamber 4 is increased, and then the muzzle velocity of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com