Waste-heat boiler

A waste heat boiler and superheater technology, applied in the boiler field, can solve the problems of low-temperature corrosion of metal, difficult cleaning of metal surface, and influence on the operation of boiler equipment, etc., and achieve the effect of avoiding low-temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

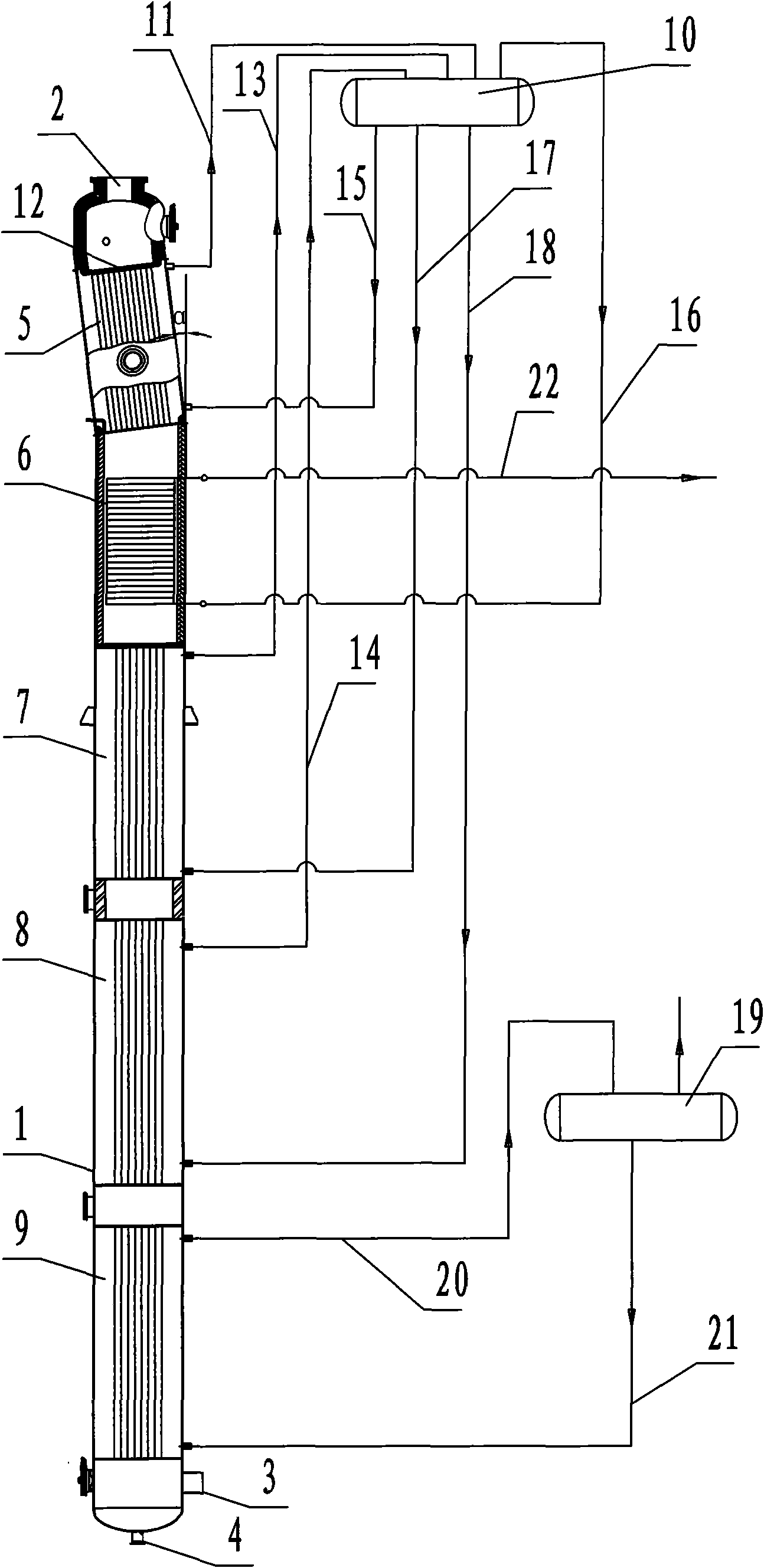

[0011] The structure and working principle of the waste heat boiler of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, a waste heat boiler includes a vertical cylindrical shell 1, a flue gas inlet 2 is provided at the upper end of the shell 1, a flue gas outlet 3 and an ash outlet 4 are provided at the lower end, and the inside of the shell 1 rises from above. The first intermediate pressure evaporator 5, the superheater 6, the second intermediate pressure evaporator 7, the third intermediate pressure evaporator 8 and the low pressure evaporator 9 are arranged in sequence below, and the first intermediate pressure evaporator 5, the second intermediate pressure The evaporator 7, the third intermediate pressure evaporator 8 and the low pressure evaporator 9 are all fire tube type (the flue gas flowing in the heat exchange tube is a fire tube type, and the flue gas flowing outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com