Method for extracting and refining docosahexaenoic acid from schizochytrium

A technology of docosahexaenoic acid and Schizochytrium, applied in the biological field, can solve the problem that fish oil resources are difficult to meet the increasing demand of DHA, and achieve the effects of reducing extraction cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

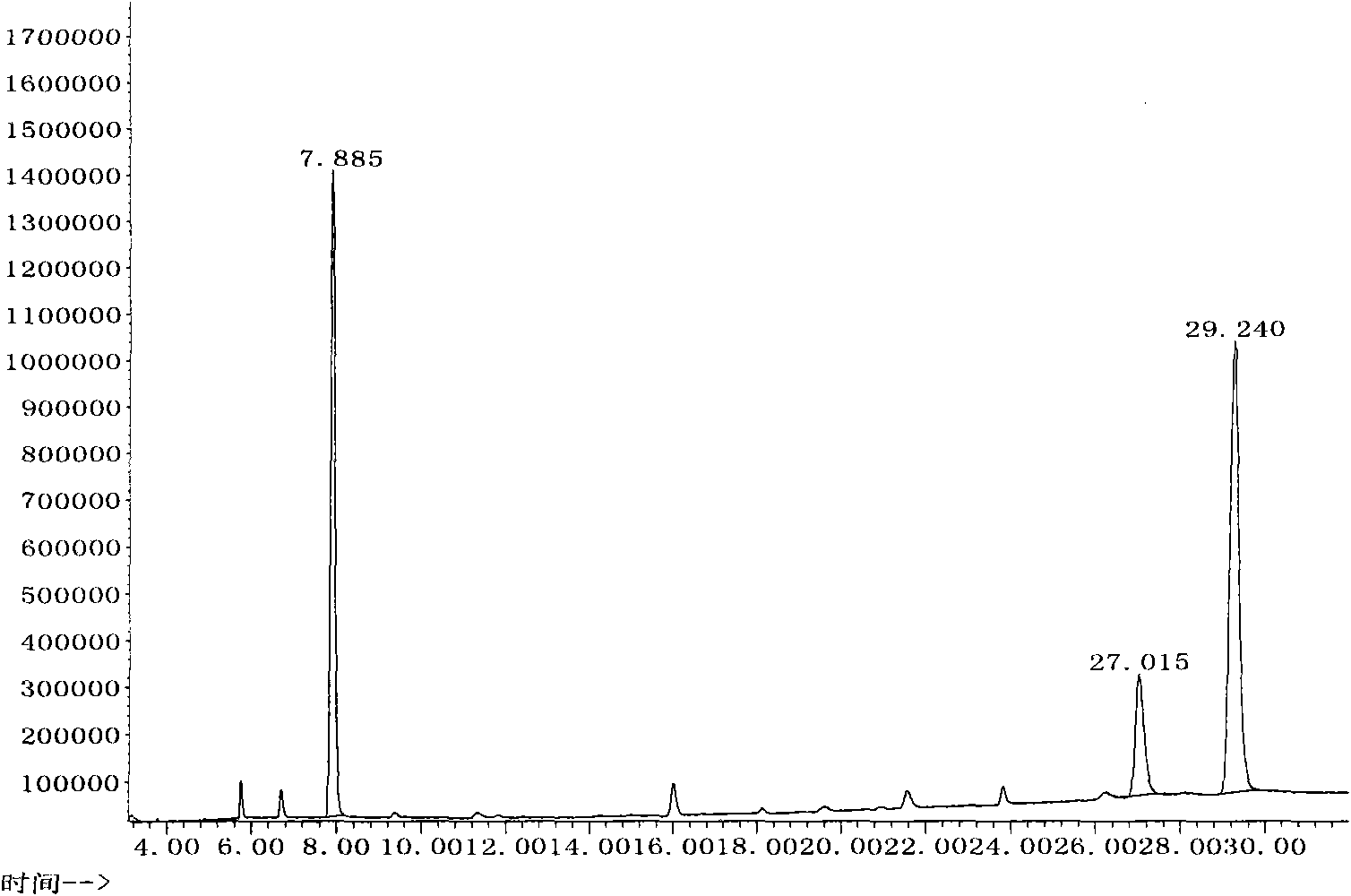

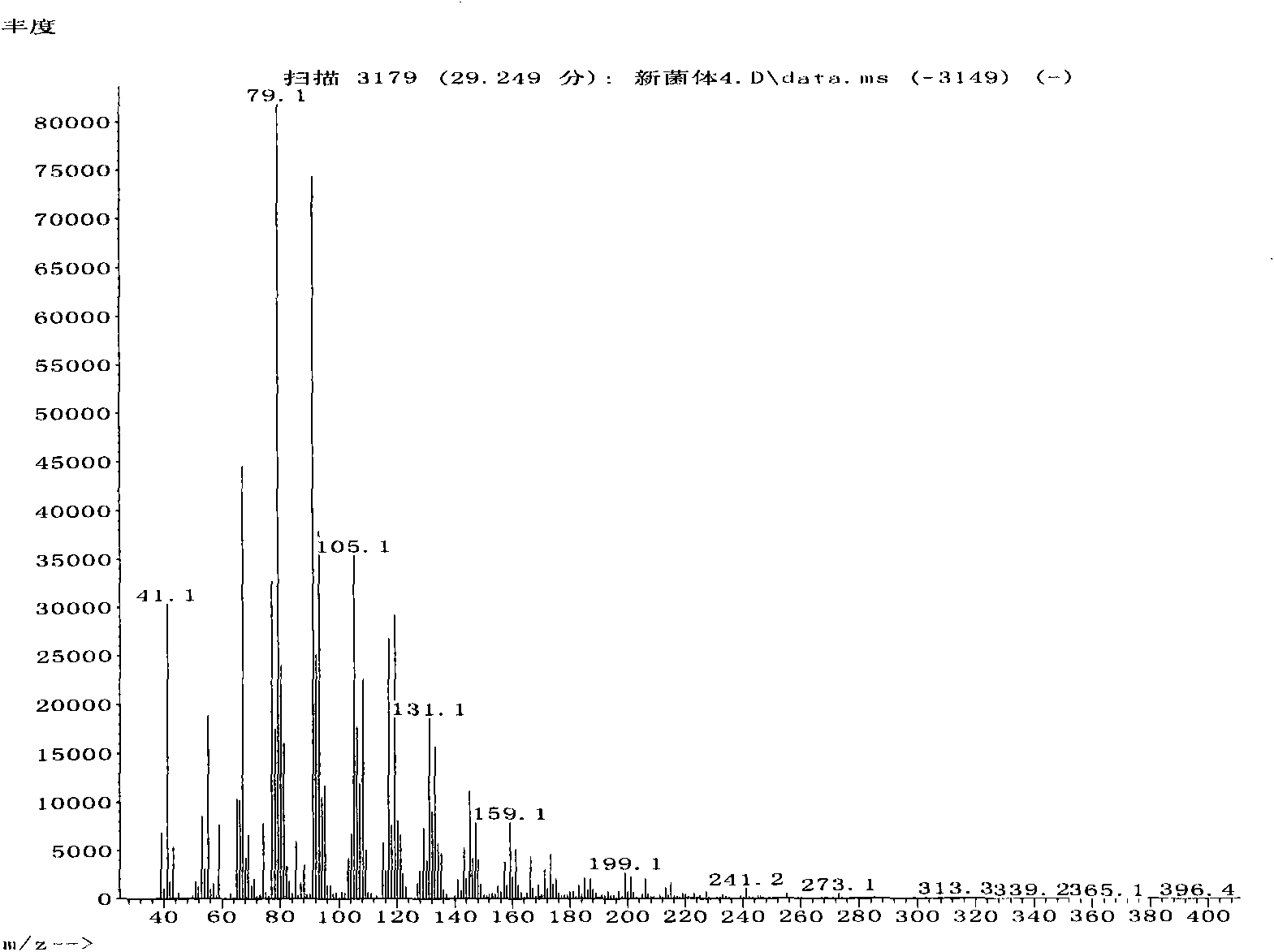

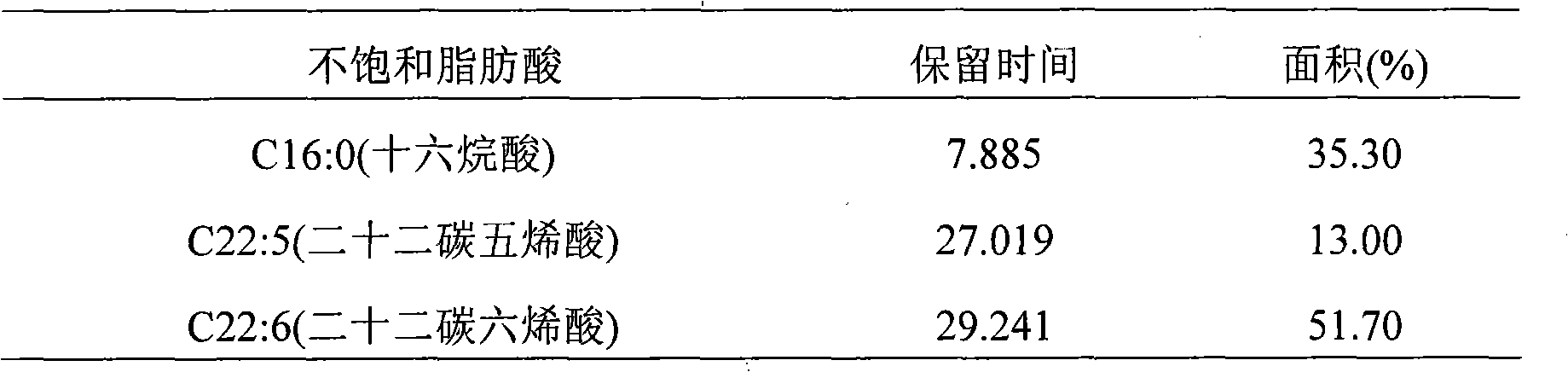

[0024] Fatty acid extraction and refining of algae harvested by fermentation in 5L fermenter

[0025] Take a tube of preserved bacteria, inoculate it into a 250mL shake flask containing 50mL of culture medium, and culture it in a shaker at 26°C at a speed of 150rpm for 36h, then take 2mL of the bacteria liquid and inoculate it into the above-mentioned fresh culture medium. The same method is continuously cultivated for three generations to obtain a seed liquid with higher vigor (in the logarithmic growth phase); then inoculate the fermenter of this seed liquid to 5L with a 10% inoculum size (the fermentation medium loading liquid is generally 100% of the fermenter) 60%, i.e. 3L, the same below), carry out stirring culture, the stirring speed is between 100-200, the air volume is at 0.2-2vvm, and the dissolved oxygen in the fermenter is controlled between 24-100% by controlling the rotating speed (fermentation The dissolved oxygen in the tank was set at 1 (ie 100%) at the begin...

Embodiment 2

[0034] Fatty acid extraction and refining of algae harvested by fermentation in 5L fermenter

[0035] Take a tube of preserved bacteria, inoculate it into a 250mL shake flask containing 50mL of culture medium, and culture it in a shaker at 26°C at a speed of 150rpm for 36h, then take 2mL of the bacteria liquid and inoculate it into the above-mentioned fresh culture medium. Continuously cultivate three generations in the same way to obtain a seed solution with higher vigor (in the logarithmic growth phase); then inoculate the seed solution with 10% inoculum in a 5L fermenter for stirring and culturing, and the stirring speed is between 100-200 During the period, the air volume is 0.2-2vvm, and the dissolved oxygen in the fermenter is controlled between 24-100% by controlling the rotating speed (the dissolved oxygen when the fermenter starts to cultivate is set at 1, which is 100%), and the pH is maintained by automatically adding ammonia water Between 6-7. The sugar concentrat...

Embodiment 3

[0044] Fatty acid extraction and refining of algae harvested by fermentation in 30L fermenter

[0045] Take a tube of preserved bacteria, inoculate it into a 250mL shake flask containing 50mL of culture medium, and culture it in a shaker at 26°C at a speed of 150rpm for 36h, then take 2mL of the bacteria liquid and inoculate it into the above-mentioned fresh culture medium. Continuously cultivate three generations in the same way to obtain a seed solution with higher vigor (in the logarithmic growth phase); then inoculate the seed solution with 10% inoculum in a 30L fermenter for stirring and culturing, and the stirring speed is between 100-200 During the period, the air volume is 0.3-3vvm, and the dissolved oxygen in the fermenter is controlled between 20-100% by controlling the rotating speed (the dissolved oxygen when the fermenter starts to cultivate is set at 1, which is 100%), and the pH is maintained by automatically adding ammonia water Between 6-7. The sugar concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com