Method and device for treating dye wastewater employing periodic reverse electrocoagulation

A technology of dye wastewater and electrocoagulation, applied in water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc., to achieve the effects of simple operation management, simple system maintenance, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

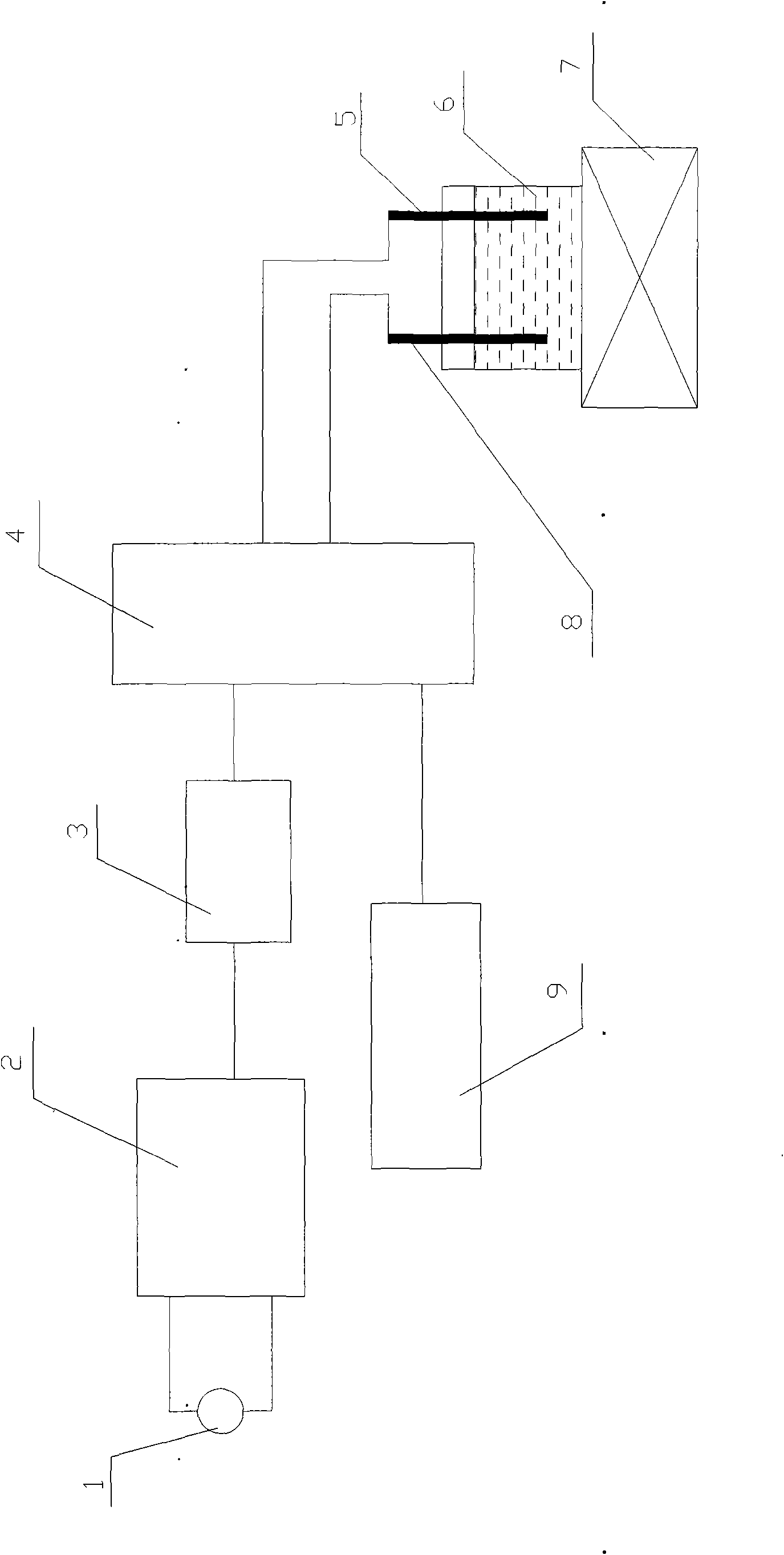

Image

Examples

Embodiment 1

[0027] Introduce the dye wastewater into the electrolytic cell, and add electrolyte to the wastewater in the electrolytic cell to make the electrolyte concentration 0.01mol / L, turn on the stirrer, control the stirring rate to 1000 rpm, control the electrode voltage to 8V, and control the current commutation cycle: 10 Seconds, adjust the pH value of the wastewater to 5, electrolytically treat it for 30 minutes, and then discharge the treated water. The electrolyte is Na 2 SO 4 .

[0028] After analysis, the chroma of the effluent is 0.028 (10 times), the COD is 45mg / L, and the removal rates of the two are 99.6% and 71.5% respectively.

[0029] The power consumption is 0.024KWh / Kg dye.

Embodiment 2

[0031] Introduce the dye wastewater into the electrolytic cell, and add electrolyte to the wastewater in the electrolytic cell to make the electrolyte concentration 0.015mol / L, turn on the stirrer, control the stirring rate to 750 rpm, control the electrode voltage to 13V, and control the current commutation cycle: 20 seconds, adjust the pH value of the wastewater to 7, electrolytically treat it for 30 minutes, and then discharge the treated water. The electrolyte is Na 2 SO 4 .

[0032] After analysis, the chroma of the effluent is 0.067 (24 times), the COD is 55mg / L, and the removal rates of the two are 99.04% and 65.2% respectively.

[0033] The power consumption is 0.046KWh / Kg dye.

Embodiment 3

[0035] Introduce the dye wastewater into the electrolytic cell, and add electrolyte to the wastewater in the electrolytic cell to make the electrolyte concentration 0.008mol / L, turn on the stirrer, control the stirring rate to 1250 rpm, control the electrode voltage to 11V, and control the current commutation cycle: 6 Seconds, adjust the pH value of the wastewater to 6, electrolytically treat it for 40 minutes, and then discharge the treated water. The electrolyte is Na 2 SO 4 .

[0036] After analysis, the chroma of the effluent is 0.110, the COD is 20mg / L, and the removal rates of the two are 96.34% and 80% respectively.

[0037] The power consumption is 0.040KWh / Kg dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com