Upper and lower combined scraping plate transmission mechanism for track type ballast scarifiers

A conveying mechanism and crawler-type technology, which is applied in the field of crawler-type mucking machine conveying mechanism, can solve the problems of easily damaged conveying mechanism, falling in the roadway, safety accidents, etc., and achieves compact structure, high conveying efficiency and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

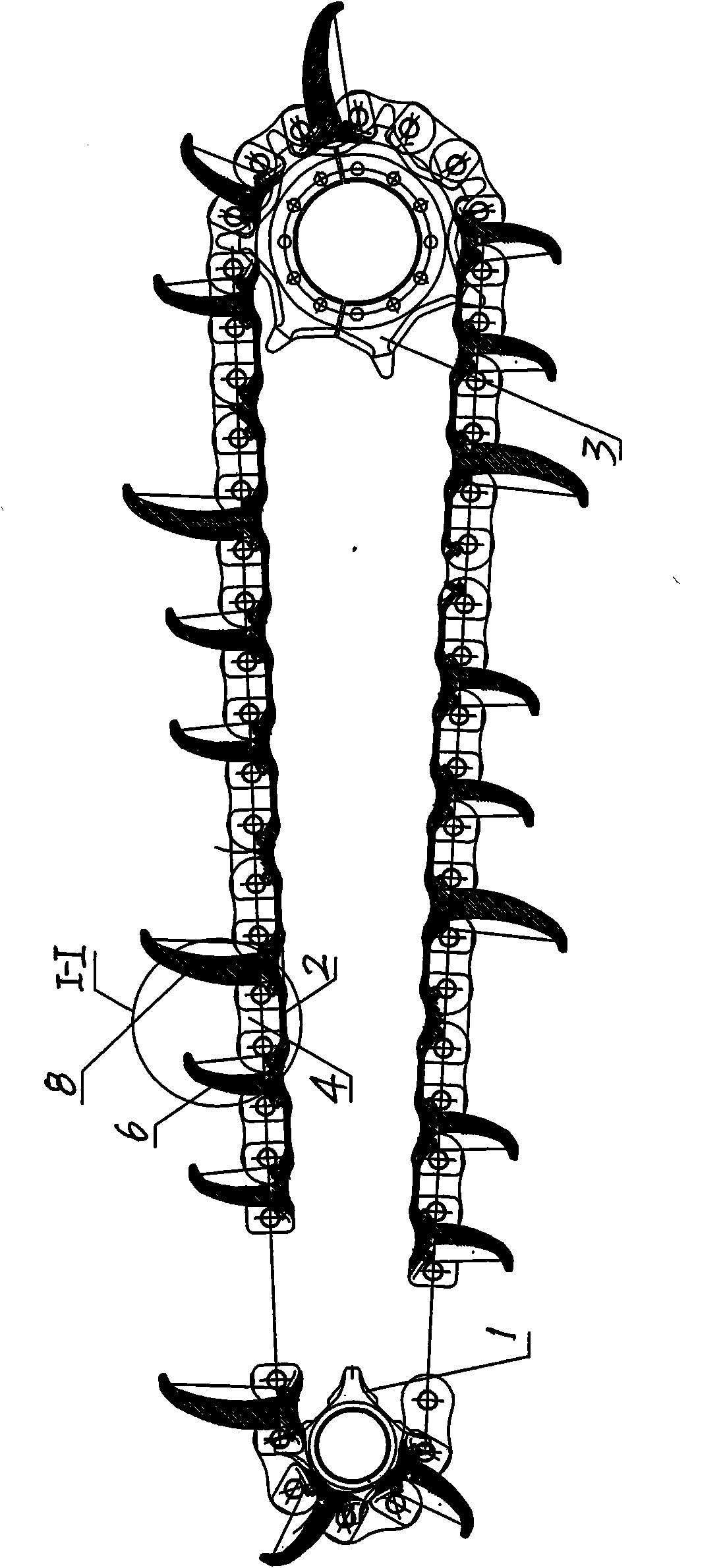

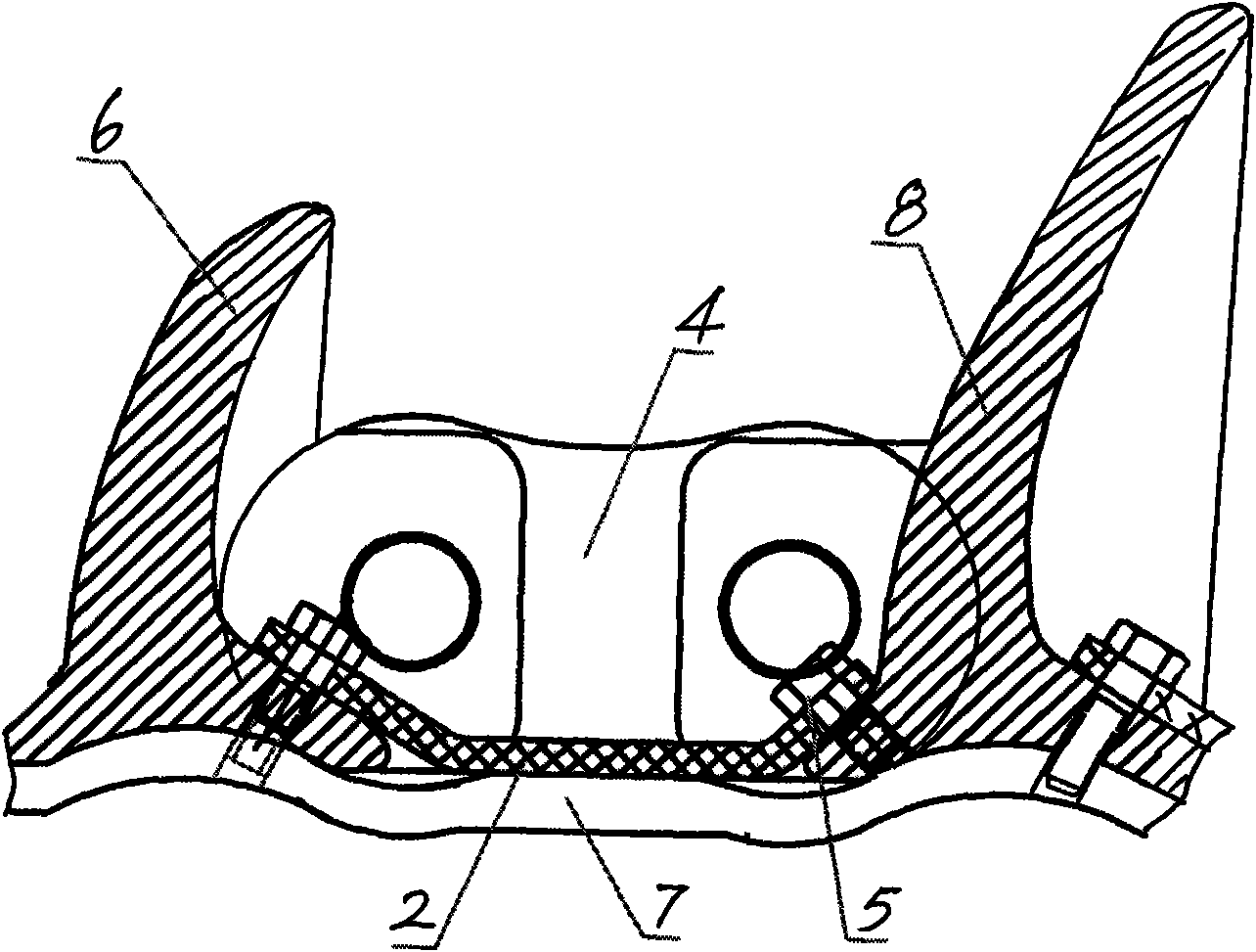

[0013] exist figure 1 and figure 2 Among them, the high and low combination scraper conveying mechanism of the crawler-type mucking machine includes two driving sprockets 3 and two driven sprockets 1 mounted on the transmission shaft, and each pair of driving sprockets and driven sprockets is provided with The roller chain is provided with an inner chain plate 7 between the two roller chains. The roller chain is formed by connecting several rollers 4 to each other. The inner chain plate is fixedly connected with a scraper I 6 and Scraper II 8, at figure 1 and figure 2 In the shown embodiment, the scraper I and the scraper II are both arc-shaped in cross-section, and the arrangement of the scraper I and the scraper II on the inner chain plate is as follows: every two rollers form a group, There are two rollers between the groups to form an interval distribution. A scraper I 6 is arranged on the inner chain plate between the rollers of the group and the position of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com