Vapor deposition material and optical thin film obtained from the same

A technology for evaporation materials and optical thin films, which is applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc. Public knowledge and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

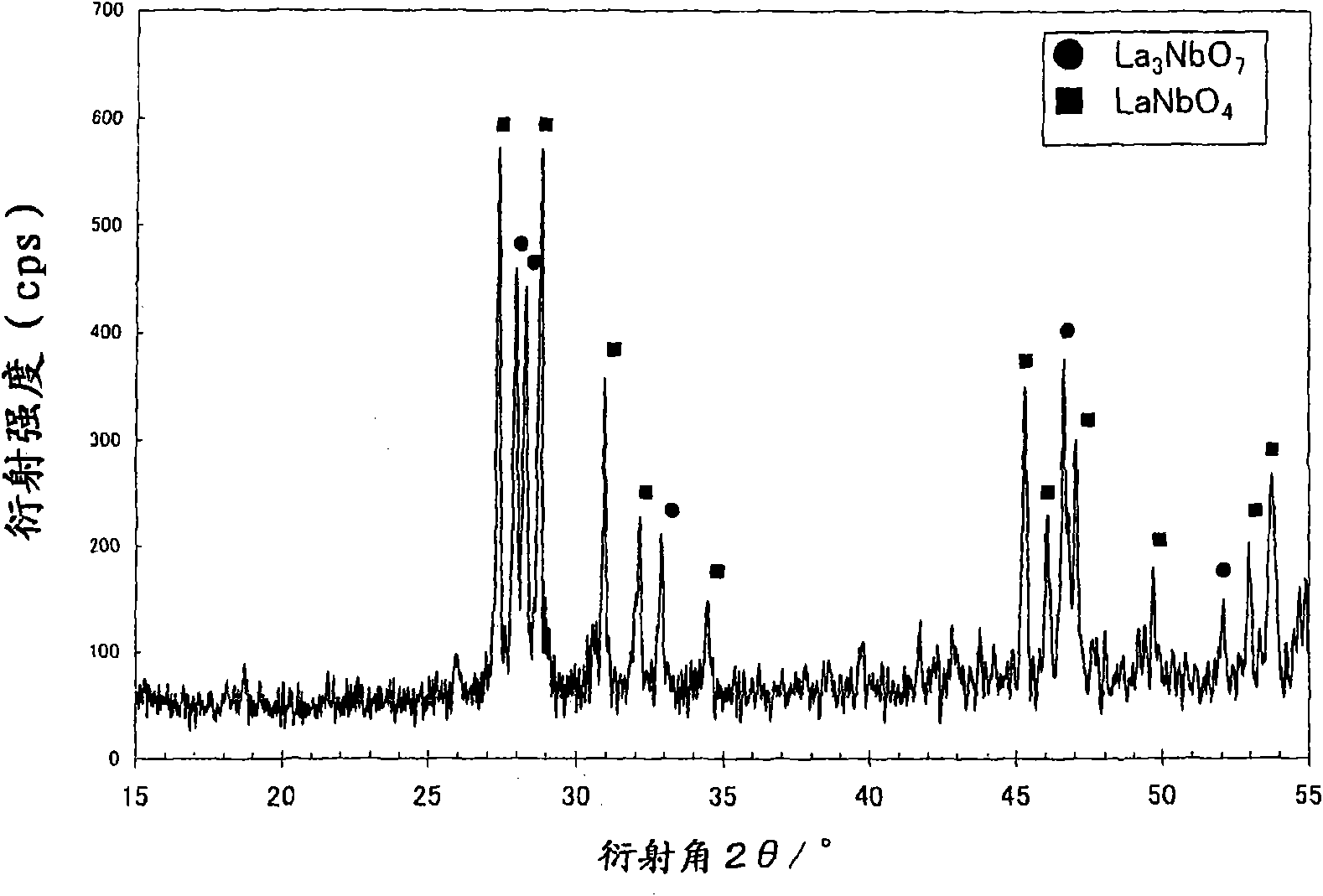

[0051] Mix the powders of niobium (V) oxide and lanthanum (III) oxide at a weight ratio of 32.9:67.1 (the molar ratio of niobium and lanthanum is 37.5:62.5), and granulate the powder mixture into granules of 1 to 3 mm in size. Fired at 1300° C. for 4 hours to obtain a granular vapor deposition material. The material is based on figure 1 The X-ray diffraction pattern shown was identified as La 3 NbO 7 and LaNbO 4 .

[0052] In a commercially available vacuum vapor deposition device, a copper-made Haslina (crucible) filled with the vapor deposition material was installed, and the device was exhausted to 1.0×10 -3 After Pa, the vapor deposition material is melted by electron beam heating to form a molten pool. Next, take the overall pressure to 1.0 x 10 -2Oxygen is introduced in the form of Pa, and only the center of the molten pool is irradiated with electron beams again to generate material vapor. On the substrate pre-set in the device and heated to 300°C, the film is for...

Embodiment 2

[0060] Mix the powders of niobium (V), lanthanum (III) oxide and metallic niobium at a weight ratio of 45.5:46.5:8.0 (the molar ratio of niobium to lanthanum is 60.0:40.0), and form the powder mixture into a sheet of 1 to 3 mm In the form of a tablet, the evaporation material in the form of a tablet is obtained by firing in a vacuum at 1600°C for 4 hours. The material was identified as LaNbO based on the X-ray diffraction pattern 4 and NbO.

[0061] For each film formed by the same method as in Example 1 using this vapor deposition material, the refractive index at a wavelength of 450 nm, the shortest transmission wavelength, and the molar ratio of niobium and lanthanum were determined. The results are shown in Tables 1 and 2. The refractive index and molar ratio are the same regardless of the number of films formed, and the shortest transmission wavelength is 305 nm.

Embodiment 3

[0063] Mix the powders of niobium (V) oxide and lanthanum (III) oxide at a weight ratio of 80.3:19.7 (the molar ratio of niobium to lanthanum is 83.3:16.7), and form the powder mixture into a tablet shape of 1-3mm, and pass through Baking was performed at 1200° C. for 4 hours in the air to obtain a tablet-shaped vapor deposition material. The material was identified as LaNb based on the X-ray diffraction pattern 5 o 14 .

[0064] For each film formed by the same method as in Example 1 using this vapor deposition material, the refractive index at a wavelength of 450 nm, the shortest transmission wavelength, and the molar ratio of niobium and lanthanum were determined. The results are shown in Tables 1 and 2. The refractive index and molar ratio are the same regardless of the number of films formed, and the shortest transmission wavelength is 330 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com