Energy storage device

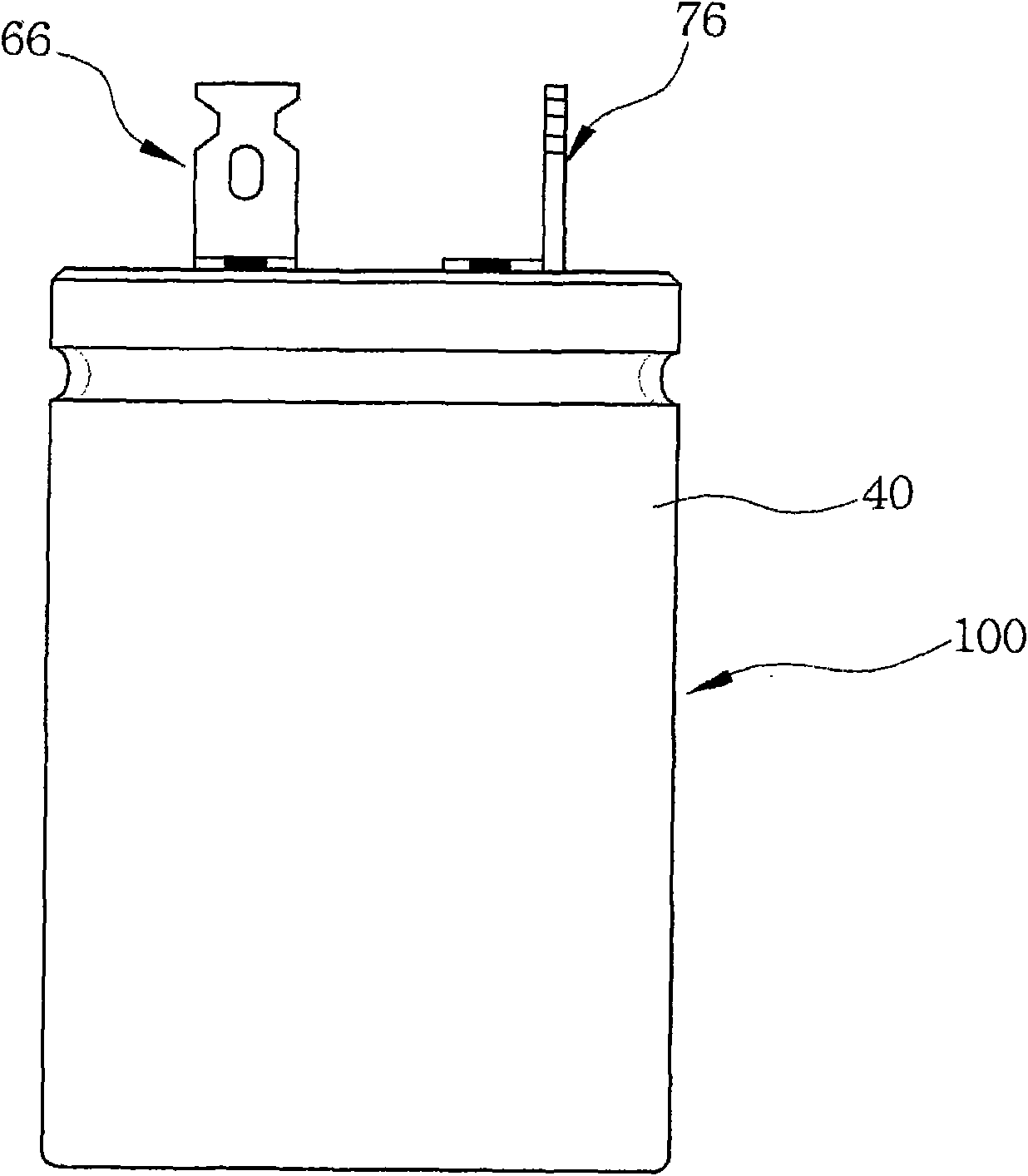

A technology for energy storage devices and electrode materials, which can be used in the manufacture of hybrid/electric double-layer capacitors, electrical components, electrolytic capacitors, etc., and can solve problems such as device performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

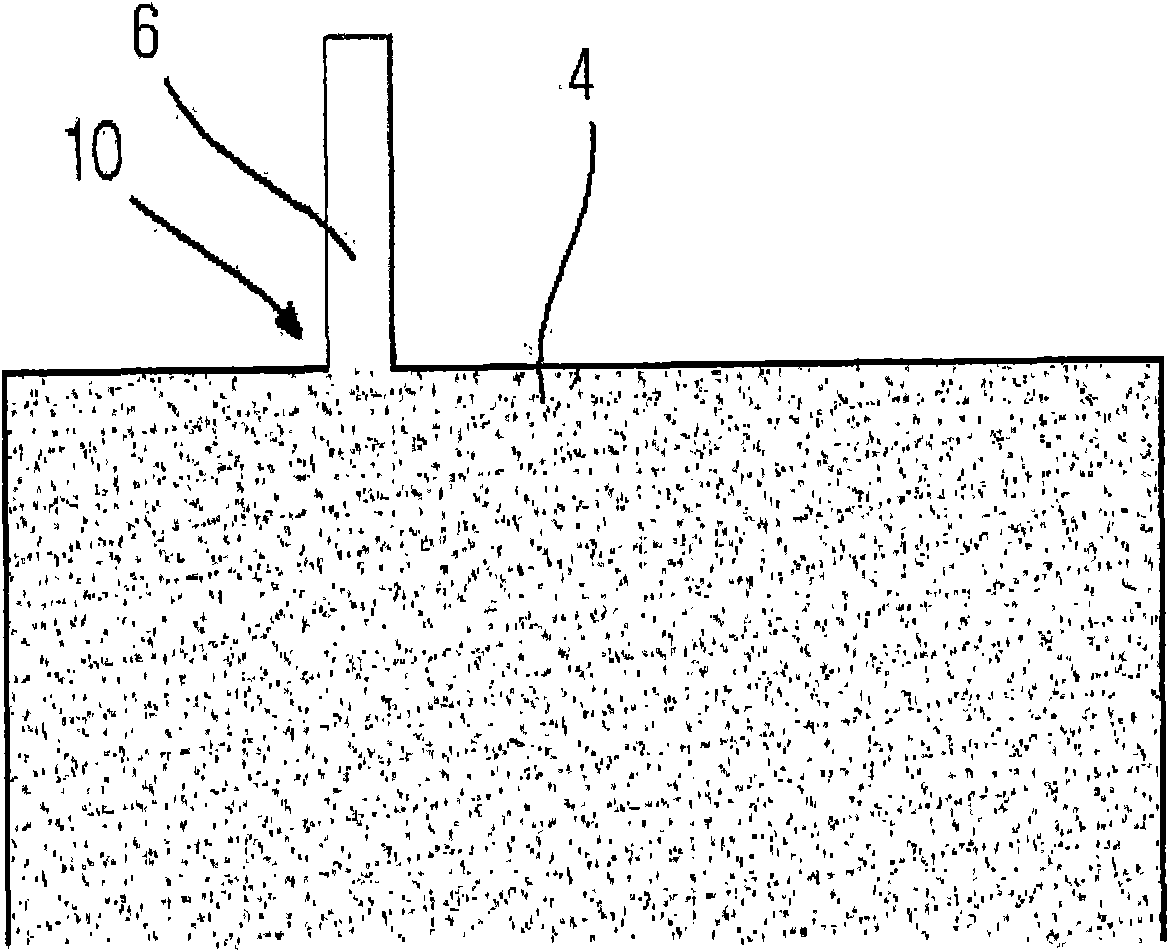

[0078] Mix LiMn in a weight ratio of approximately 80:15:5 2 o 4, conductive material and binder to prepare cathode electrode slurry. A slurry for the anode electrode was prepared by mixing activated carbon, conductive material, and binder in a weight ratio of about 80:15:5. Each slurry was coated on an aluminum current collector to form a cathode electrode and an anode electrode. At this time, superfine carbon powder (super P) is used as a conductive material, and a mixture of PTFE, CMC and SBR is used as a binder. The slurry-coated current collector was compressed by applying pressure thereto, and dried in a vacuum oven at about 120° C. for about 48 hours.

[0079] A capacitor cell is fabricated using a pair of electrodes, a separator, and an electrolyte. At this time, the separator was a porous cellulose-based separator, and the capacitor unit was cylindrical. Et dissolved in acetonitrile solvent 4 NBF 4 and LiBF 4 used as an electrolyte. The capacitor unit charges...

example 2

[0090] Mix LiMn in a weight ratio of approximately 80:15:5 2 o 4 , conductive material and binder to prepare cathode electrode slurry. A slurry for the anode electrode was prepared by mixing activated carbon, conductive material, and binder in a weight ratio of about 80:15:5. Each slurry was coated on an aluminum current collector to form a cathode electrode and an anode electrode. At this time, ultra-fine carbon powder is used as a conductive material, and a mixture of PTFE, CMC and SBR is used as a binder. The current collector coated with the slurry was compressed by applying pressure thereon, and dried in a vacuum oven at about 120° C. for about 48 hours.

[0091] A capacitor cell is fabricated using a pair of electrodes, a separator, and an electrolyte. At this time, the separator is a porous cellulose-based separator, and the capacitor unit has a cylindrical shape. LiBF dissolved in acetonitrile solvent 4 used as an electrolyte. The capacitor unit is charged / disch...

example 3

[0109] Dissolve 1M LiBF in a mixed solvent of propylene carbonate (PC: propylene carbonate) and ethylene carbonate (EC: ethylenecarbonate) 4 An electrolyte was prepared with 1M TEATFB (tetraethylammonium tetrafluoroborate) as an electrolyte salt. The conductivity of the electrolyte was measured by an Orion Conductivity Meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com