Method and system for rapidly evaluating corrosion resistance of in-service coating

A technology for corrosion resistance and coating, applied in the field of corrosion resistance evaluation of in-service coatings, can solve problems such as inconvenience in rapid evaluation, and achieve the effects of rapid evaluation of corrosion resistance, convenient use and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

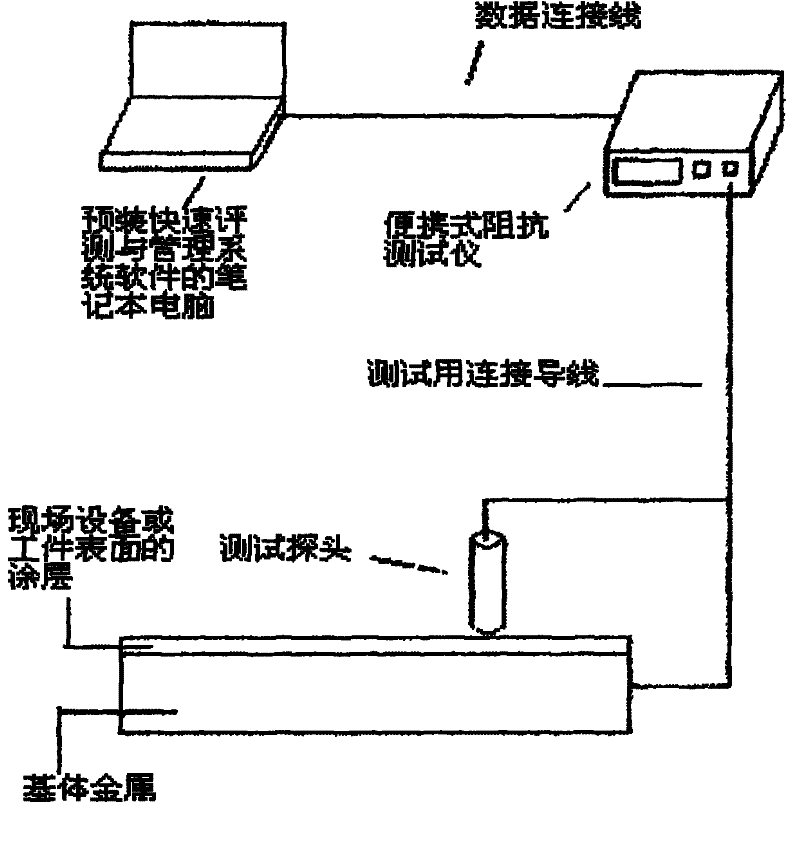

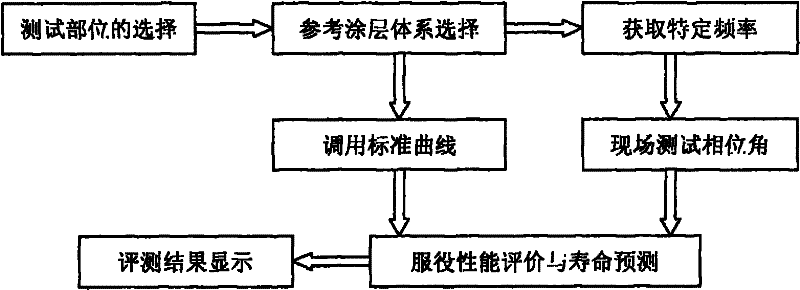

Method used

Image

Examples

example 1

[0037] Example 1: Inorganic zinc-rich primer / epoxy sealer / epoxy mica iron intermediate paint / acrylic polyurethane topcoat

[0038] Bottom plate material: Q235 carbon steel

[0039] Coating method: brush coating

[0040] Coating thickness: inorganic zinc-rich primer 75μm

[0041] Epoxy sealer 20μm

[0042] Epoxy mica iron intermediate paint 90μm

[0043] Acrylic polyurethane topcoat 85μm

[0044] Total coating thickness: 270μm

[0045] Sample area: 12.5cm 2

[0046] Corrosion environment: 3.5% sodium chloride solution immersion + ultraviolet radiation combined effect

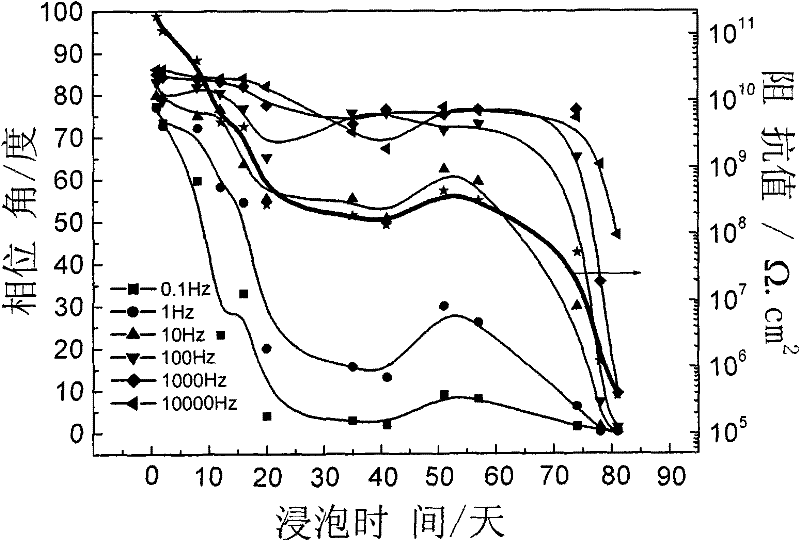

[0047] by comparison image 3 Impedance value at 0.01Hz frequency (|Z| 0.01Hz ) change curve with soaking time and the change curve of phase angle with soaking time at different frequencies. 0.01Hz ) has the closest variation trend.

[0048] The coating appearance and impedance value |Z| 0.01Hz and the relationship between the phase angle at a specific frequency (10Hz) ...

example 2

[0050] Example 2: Inorganic zinc-rich primer / epoxy sealer / epoxy mica iron intermediate paint / aliphatic polyurethane topcoat

[0051] Bottom plate: Q235 carbon steel

[0052] Coating method: brush coating

[0053] Coating thickness: inorganic zinc-rich primer 70μm

[0054] Epoxy sealer 25μm

[0055] Epoxy mica iron intermediate paint 105μm

[0056] Aliphatic polyurethane topcoat 80μm

[0057] Total coating thickness: 280μm

[0058] Sample area: 12.5cm 2

[0059] Corrosion environment: 3.5% sodium chloride solution immersion + ultraviolet radiation combined effect

[0060] by comparison Figure 4 Impedance value at 0.01Hz frequency (|Z| 0.01Hz ) with immersion time and the phase angle at different frequencies with immersion time, it can be seen that the change of phase angle at 10Hz frequency is the closest to the change trend of impedance value.

[0061] The coating appearance and impedance value |Z| 0.01Hz and the relationship between t...

example 3

[0063] Example 3: 801 epoxy zinc-rich primer / 701-2 epoxy mica gray thick build primer / 652 aliphatic polyurethane topcoat

[0064] Bottom plate: Q235 carbon steel

[0065] Coating method: brush coating

[0066] Coating thickness: 801 epoxy zinc-rich primer 50μm

[0067] 701-2 Epoxy mica gray thick build primer 45μm

[0068] 652 aliphatic polyurethane 25μm

[0069] Total coating thickness: 120μm

[0070] Sample area: 12.5cm 2

[0071] Corrosion environment: 3.5% sodium chloride solution immersion + ultraviolet radiation combined effect

[0072] by comparison Figure 5 Impedance value at 0.01Hz frequency (|Z| 0.01Hz ) with immersion time and the phase angle with immersion time at different frequencies, it can be seen that the change of phase angle at 10 Hz frequency is the closest to the change trend of impedance value.

[0073] The coating appearance and impedance value |Z| 0.01Hz and the relationship between the phase angle at a specific frequency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com