Composite type polymeric flocculant

A polymer flocculant, composite technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of discounted effect, instability, performance cannot be guaranteed, etc., to achieve good effect, obvious effect, high efficiency and wide application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Composite polymer flocculant, which is prepared from elm fur powder, cactus powder, sodium carboxymethyl cellulose and polyacrylamide raw materials, the mass percentage of each raw material is: elm fur powder: 42%; cactus powder: 32% %; sodium carboxymethylcellulose: 8%; polyacrylamide: 18%.

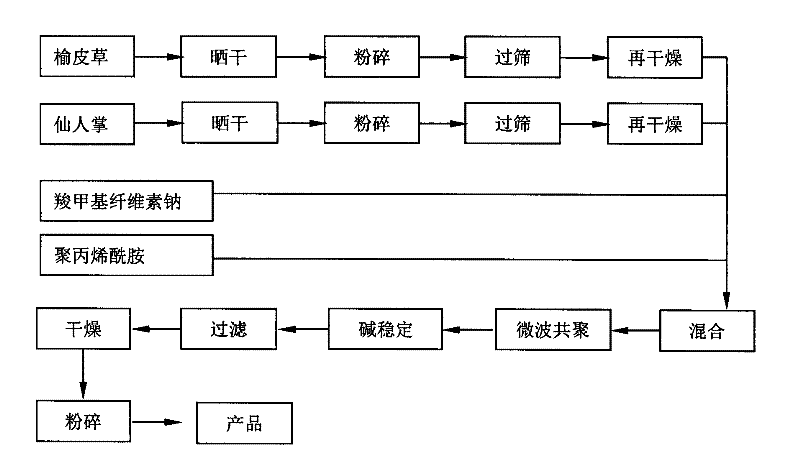

[0015] The preparation method of above-mentioned composite polymer flocculant, such as figure 1 As shown, it includes the following steps;

[0016] 1) Preparation of raw materials: dry and pulverize elm fur, then pass through a 50-mesh sieve, and then dry to obtain elm fur powder; dry and pulverize cactus, then pass through a 50-mesh sieve, and then dry to obtain cactus powder; The mass percentage of raw materials is: elm fur powder 42%, cactus powder 32%, sodium carboxymethyl cellulose 8%, polyacrylamide 18%, select elm fur powder, cactus powder, sodium carboxymethyl cellulose and polypropylene The amide raw material is spare;

[0017] 2) Mix elm fur powder, cactus powder, sod...

Embodiment 2

[0032] Composite polymer flocculant, which is prepared from elm fur powder, cactus powder, sodium carboxymethyl cellulose and polyacrylamide raw materials, the mass percentage of each raw material is: elm fur powder: 40%; cactus powder: 30% %; sodium carboxymethylcellulose: 10%; polyacrylamide: 20%.

[0033] The preparation method of the above-mentioned composite polymer flocculant is basically the same as that of Example 1, except that the ratio of raw materials is different.

Embodiment 3

[0035] Composite polymer flocculant, which is prepared from elm fur powder, cactus powder, sodium carboxymethyl cellulose and polyacrylamide raw materials, the mass percentage of each raw material is: elm fur powder: 45%; cactus powder: 35% %; sodium carboxymethylcellulose: 5%; polyacrylamide: 15%.

[0036] The preparation method of the above-mentioned composite polymer flocculant is basically the same as that of Example 1, except that the ratio of raw materials is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com