Punching method for preventing plate corner part in car door from wrinkling

A technology for car doors and panel corners, which is applied in the field of stamping processing of automobile panels. It can solve problems such as affecting product appearance, difficult processing in subsequent processes, and poor part size and surface shape, so as to reduce the amount of process shaping and solve product problems. wrinkled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

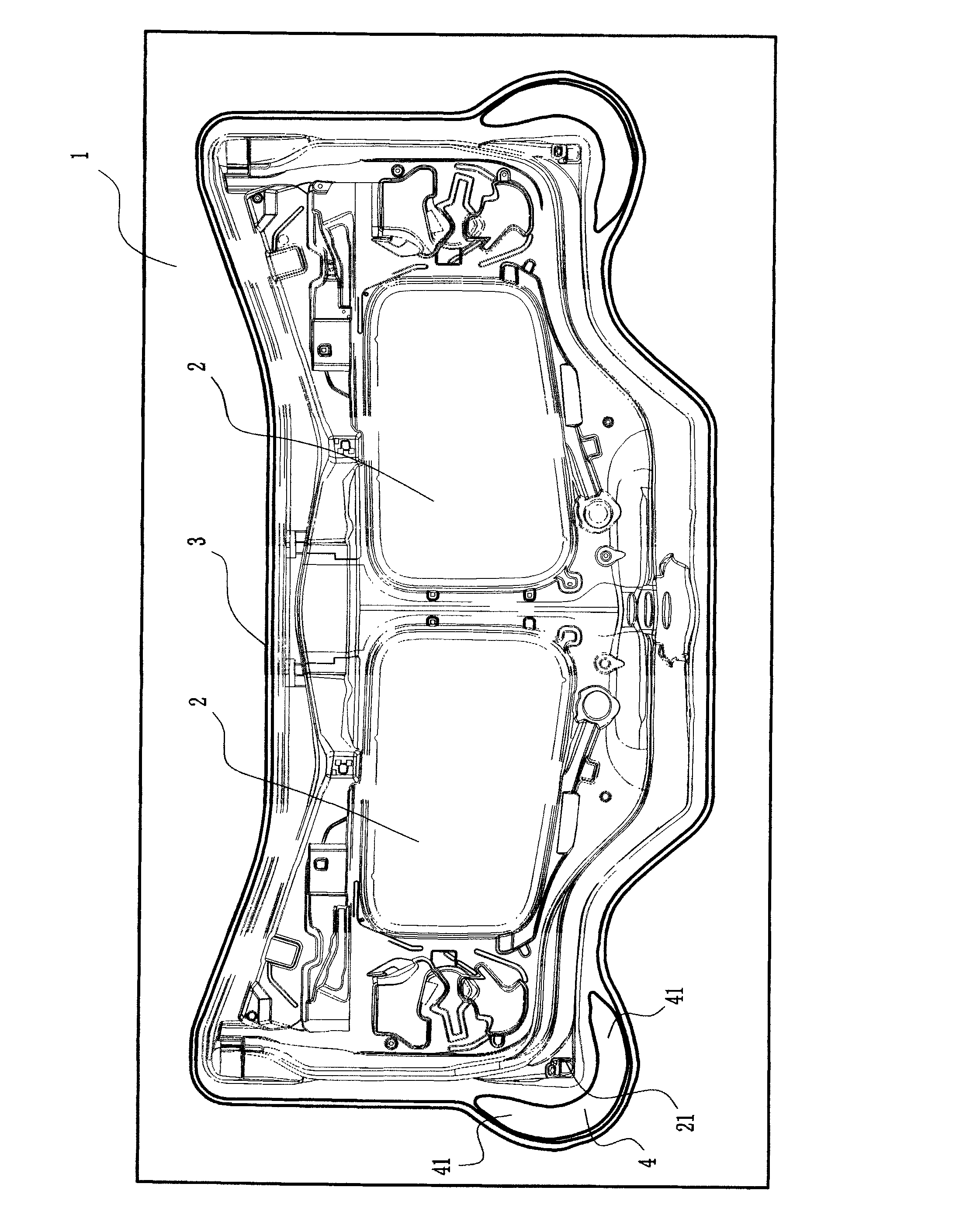

[0015] As shown in the drawings, in this embodiment, two left and right door inner panels 2 are stamped and formed by using one plate 1 , and surrounding drawbeads 3 are provided on the plates around the door inner panel 2 . In order to avoid wrinkling at the corners 21 of the inner panel of the car door, the method adopted in this embodiment includes: adding technological ribs to supplement the shape in the drawing process. The arc-shaped rib 4 is arranged around the corner 21 of the inner panel of the vehicle door.

[0016] Wherein, both ends of the arc-shaped rib 4 have transition ribs 41 extending from the endpoints of the arc-shaped rib 4 to the straight edge of the door inner panel, and the raised height and width of the transition rib 41 gradually become zero. The included angle between the two transition ribs 41 is not greater than the angle of the corner 21 of the inner panel of the vehicle door.

[0017] The working principle of this embodiment:

[0018] By changi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com