Sterilization combination for preventing and curing downy mildew of fruits and vegetables and aqueous emulsion thereof and preparation method thereof

A composition and technology of downy mildew, applied in botany equipment and methods, fungicides, biocides, etc., can solve the problems of not conforming to the trend of green and environmental protection society, increased resistance of bacteria, high pesticide residues, etc., and achieve relief Bacteria resistance, slowing down of drug resistance, low pesticide residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

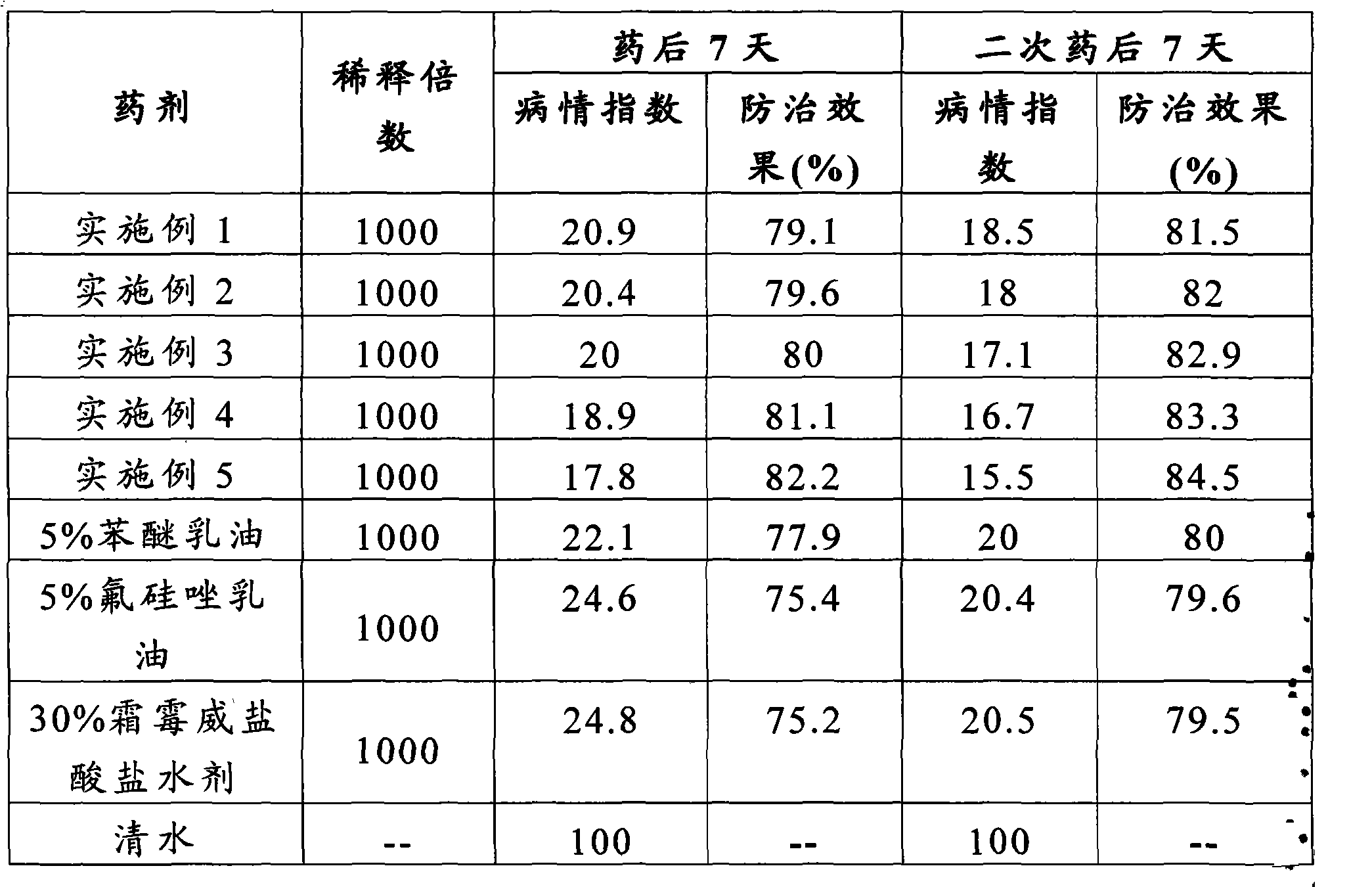

Examples

Embodiment 1

[0032] Prepared with 30% flusilazole propamocarb hydrochloride aqueous emulsion, the distribution ratio of each component is by weight:

[0033] Flusilazole 5%

[0034] Propamocarb Hydrochloride 25%

[0035] Phenylphenol Ethoxylate 5%

[0036] Castor Oil Ethoxylates 3%

[0037] Mineral spirit 10%

[0038] Glycerol 4%

[0039] Silicone oil 0.2%

[0040] Gum Arabic 0.25%

[0041] water balance

[0042] The preparation process is as follows: dissolve flusilazole with solvent oil, add phenethylphenol polyoxyethylene ether, castor oil polyoxyethylene ether, silicone oil, and glycerol and stir evenly as the oil phase, and mix gum arabic, propamocarb The hydrochloride is added to water and stirred evenly as the water phase, and the water phase is slowly added to the oil phase under stirring at 1000-2000r / min, and then sheared at a high speed at 4000-5000r / min for 30min to obtain the product.

Embodiment 2

[0044] 30% difenoconazole · propamocarb hydrochloride aqueous emulsion preparation, the distribution ratio of each component is by weight:

[0045] Difenoconazole 5%

[0046] Propamocarb Hydrochloride 25%

[0047] Fatty alcohol polyoxyethylene ether 5%

[0048] Castor Oil Ethoxylates 3%

[0049] Toluene 10%

[0050] Glycerol 4%

[0051] Silicone oil 0.2%

[0052] Xanthan Gum 0.25%

[0053] water balance

[0054] The preparation process is as follows: dissolve difenoconazole with toluene, add fatty alcohol polyoxyethylene ether, castor oil polyoxyethylene ether, silicone oil, and glycerin and stir evenly as the oil phase, and mix xanthan gum, propamocarb The hydrochloride is added to water and stirred evenly as the water phase, and the water phase is slowly added to the oil phase under stirring at 1000-2000r / min, and then sheared at a high speed at 4000-5000r / min for 30min to obtain the product.

Embodiment 3

[0056] 35% prochloraz propamocarb hydrochloride aqueous emulsion preparation, the distribution ratio of each component is by weight:

[0057] Prochloraz 5%

[0058] Propamocarb Hydrochloride 30%

[0059] Phenylphenol Ethoxylate 5%

[0060] Alkylphenol polyoxyethylene ether formaldehyde condensate 3%

[0061] Xylene 15%

[0062] Propylene Glycol 4%

[0063] Silicone oil 0.2%

[0064] Carboxymethylcellulose 0.25%

[0065] water balance

[0066] The preparation process is as follows: dissolve prochloraz in xylene, add styrene ethylphenol polyoxyethylene ether, alkylphenol polyoxyethylene ether formaldehyde condensate, silicone oil, and propylene glycol and stir evenly as the oil phase, and carboxymethyl fiber Add the element and propamocarb hydrochloride into water and stir evenly to make the water phase, slowly add the water phase to the oil phase under stirring at 1000-2000r / min, and then shear at a high speed at 4000-5000r / min for 30min to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com