Method and device for implanting heavy ion beams into synchrotron

A technology of synchrotron and heavy ion beam, which is applied in the direction of magnetic resonance accelerators, accelerators, electrical components, etc., can solve the problems of high precision in the production of electrostatic deflection plates, the inability to change the ion charge state, and low injection efficiency, etc., to achieve operation Stability, long life, and high injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

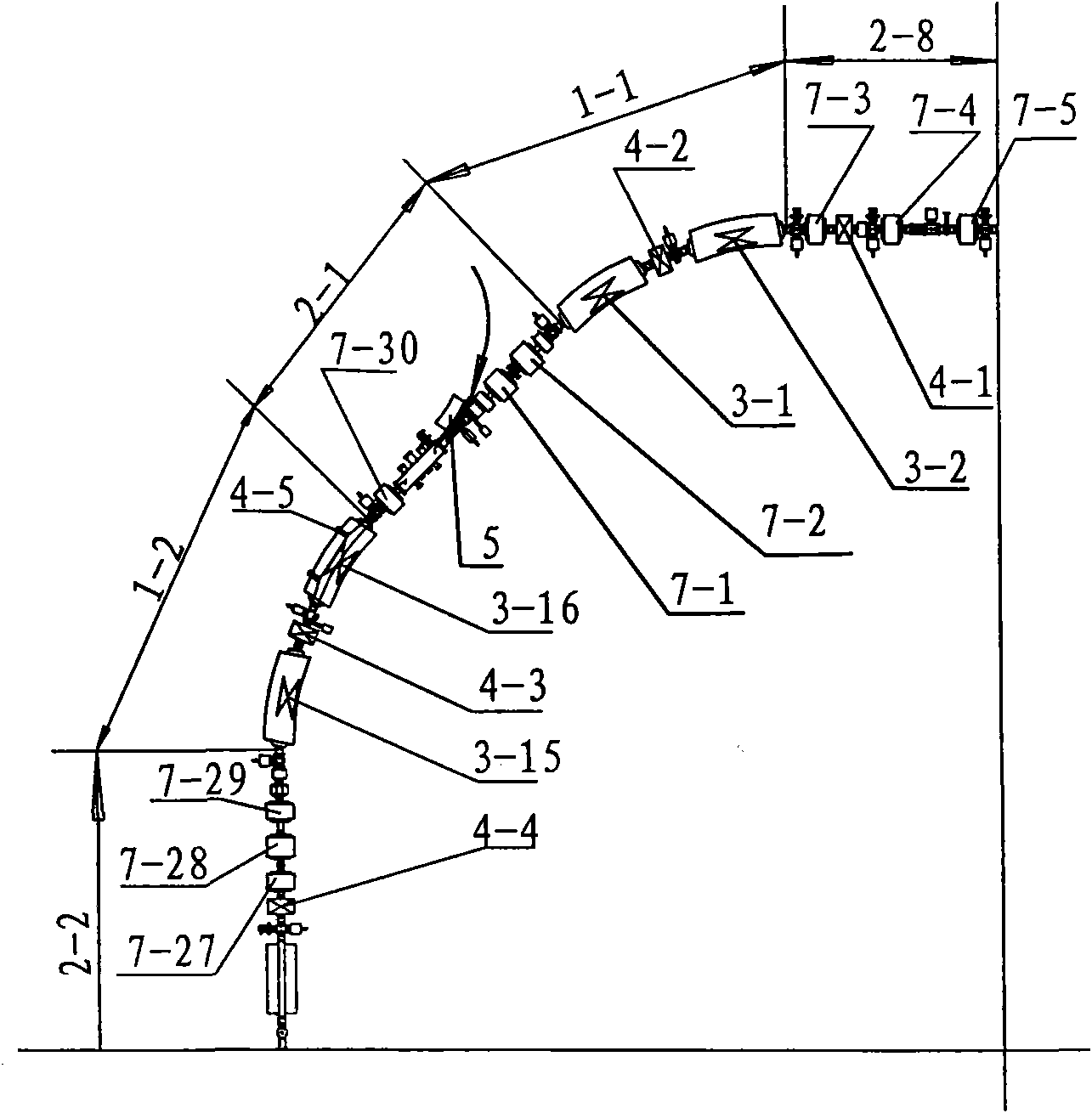

[0034] Example 2: see figure 1 , with figure 1 is the injection segment in the synchrotron. A device for injecting a heavy ion beam into a synchrotron, comprising curved sections 1-1 and 1-2 at both ends of the injection device 2-1, and a straight line section 2-2 downstream of the curved section 1-2 , a straight line section 2-8 is provided upstream of the curved section 1-1.

[0035] Described curve segment 1-1 comprises dipole magnet 3-1, 3-2, and described curve segment 1-2 comprises dipole magnet 3-15, 3-16; In two dipole magnets 3-1 , 3-2 is provided with kick rail magnet 4-2, is provided with kick rail magnet 4-3 between two two pole magnets 3-15,3-16; Straight line section 2-2 includes quadrupole magnet 7- 27,7-28,7-29 and kick rail magnet 4-4, straight line section 2-8 includes four-stage magnet 7-3,7-4,7-5 and kick rail magnet 4-1; 3-16 is provided with a peeling film 4-5; a cutting magnet 5 and quadrupole magnets 7-1, 7-2, 7-30 are provided in the straight secti...

Embodiment 3

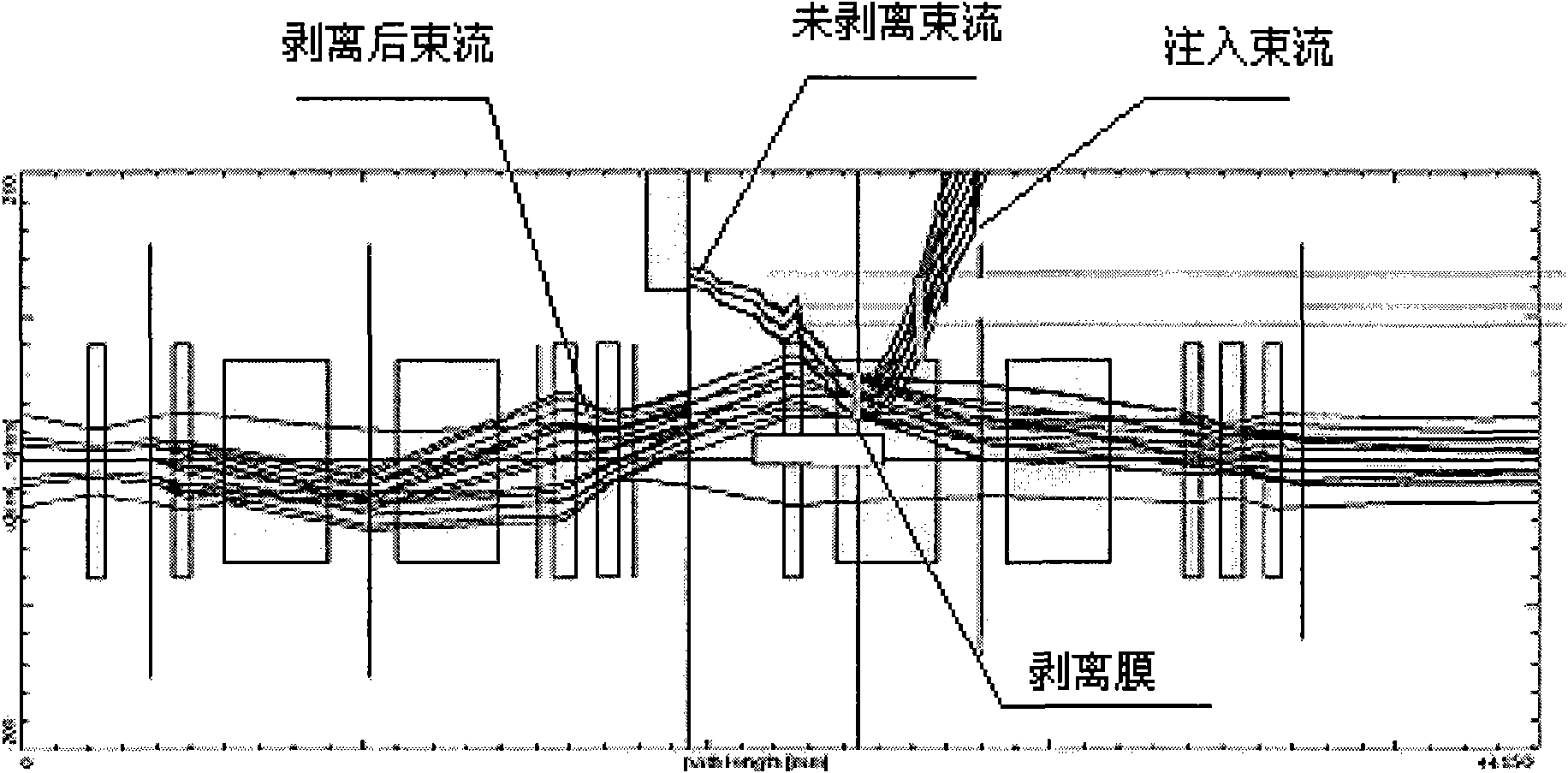

[0036] Embodiment 3: The peeling film is a carbon film prepared by a DC arc discharge method. When the incompletely stripped heavy ion beam passes through the stripped film, some or all of the electrons outside the nucleus will be lost, and the number of lost electrons is related to the thickness of the film. The design of the release film ended up with the following characteristics:

[0037] 1. It has a large effective area, and the maximum effective area of the finally developed release film is 40×40mm 2 .

[0038]2. In order to release the film itself without affecting the track of the stored ions, the release film adopts a U-shaped target frame, and the width of the frame is less than 2mm.

[0039] 3. In order to improve the uniformity of the film, so that the energy of the ions after stripping has less dispersion. The release film adopts a double-layer structure.

[0040] 4. According to the energy of different implanted ions and the requirements for the charge stat...

Embodiment 4

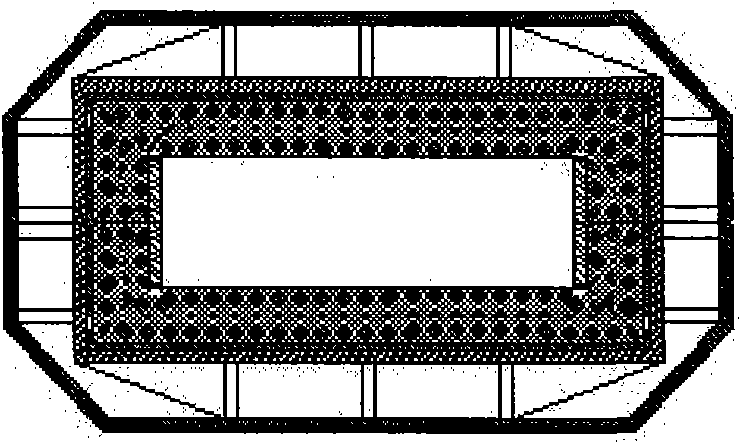

[0041] Example 4: image 3 It is a schematic diagram of a kicking magnet. In order to reduce the eddy current loss, the iron core is generally made of ferrite material. A layer of 5mm thick copper shielding shell is added to the steel structure shell of the magnet. In addition, since the magnetic field works in a very fast pulsed manner, a special ceramic vacuum chamber is used to eliminate the eddy currents generated by the pulsed magnetic field on the walls of the vacuum chamber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com