Preparation method of nano attapulgite adsorbent

A technology of nano-attapulgite and attapulgite, applied in chemical instruments and methods, and other chemical processes, to achieve the effect of simple process and equipment requirements and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

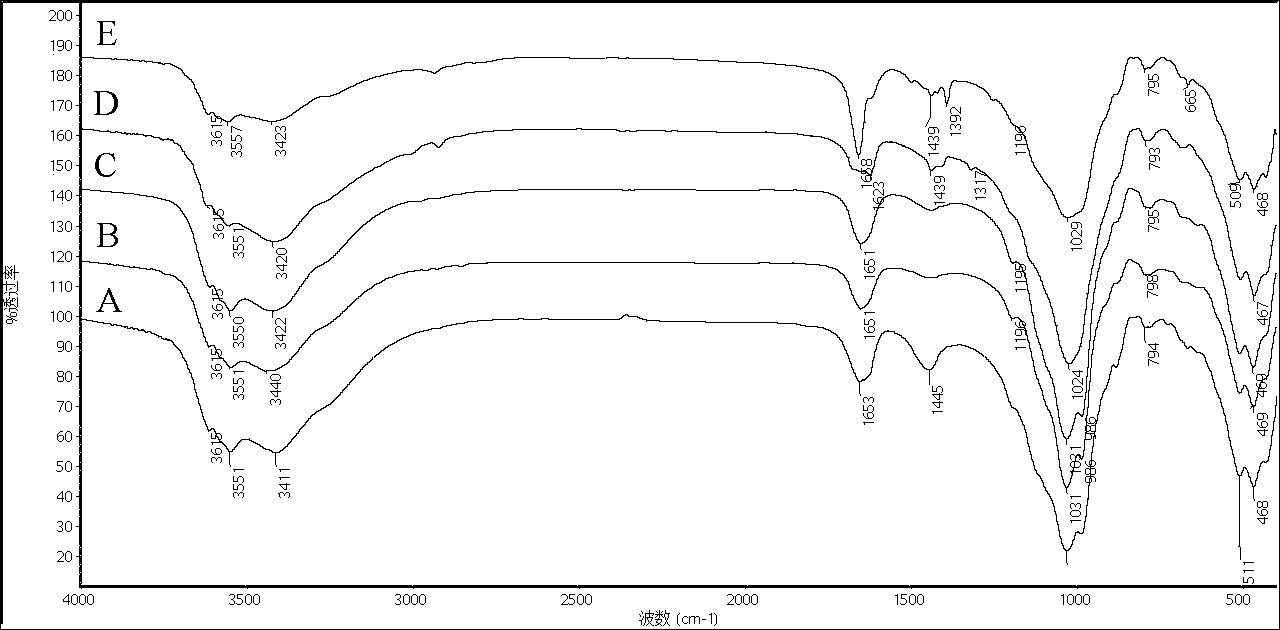

[0019] Example 1: Disperse 2 g of attapulgite clay in 600 mL of dimethylformamide under stirring conditions, stir for 30 min to disperse evenly, place in a 1 L autoclave, react at 120 °C for 120 h, cool down naturally, separate, and dry. Crushed through a 200-mesh sieve to obtain a functionalized attapulgite adsorbent. Compared with the original soil, the adsorption of zearalenone and methylene blue dye by this adsorbent increased by 21.9 and 118.5%, respectively.

Embodiment 2

[0020] Example 2: Under stirring conditions, 6 g of attapulgite clay was dispersed in 600 mL of dimethylformamide, stirred for 30 min to disperse evenly, and then placed in a 1 L high-pressure reactor at 180 °C for 48 h, cooled naturally, and separated. Dry, crush and pass through a 200-mesh sieve to obtain a functionalized attapulgite adsorbent. Compared with the original soil, the adsorption of zearalenone and methylene blue dye by this adsorbent increased by 33.9 and 158.3%, respectively.

Embodiment 3

[0021] Example 3: Under stirring conditions, disperse 20 g of attapulgite clay in 600 mL of dimethyl sulfoxide, stir for 30 min to disperse evenly, place in a 1 L autoclave, react at 180 °C for 96 h, cool down naturally, separate, dry, and pulverize Pass through a 200-mesh sieve to obtain a functionalized attapulgite adsorbent. Compared with the original soil, the adsorption of zearalenone and methylene blue dye by this adsorbent increased by 10.8 and 132.6%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com