Measuring method of welding joint shaping organizational characteristics

A technology of welded joints and measurement methods, which is applied in the measurement of welded joints' forming structure characteristics and the evaluation of welding quality, which can solve the problems of inability to accurately identify contour feature points, etc., and achieve the effects of eliminating burrs, good results, and reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] figure 2 It is a flowchart of steps of the present invention. The redundant curve is y=ax 2 +bx+c and x=ay2 +by+c two forms, a, b, c are the coefficients of the quadratic term, the first term, and the constant term respectively, which are all fitted by the least square method, x is the abscissa variable, and y is the ordinate variable. The curves used in the steps are the embodiment of these two forms, and the meanings of the parameters are the same as above.

[0030] The specific steps are:

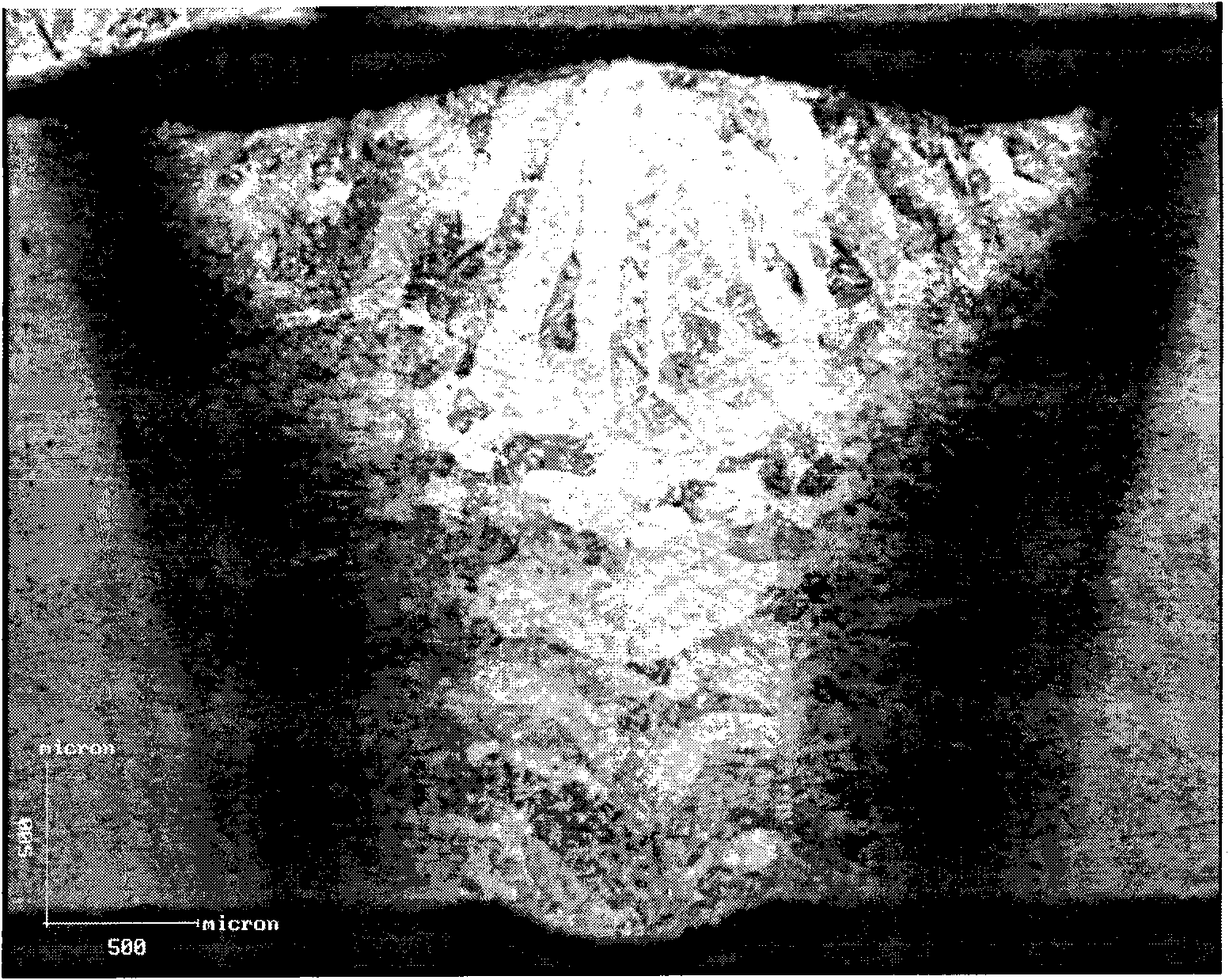

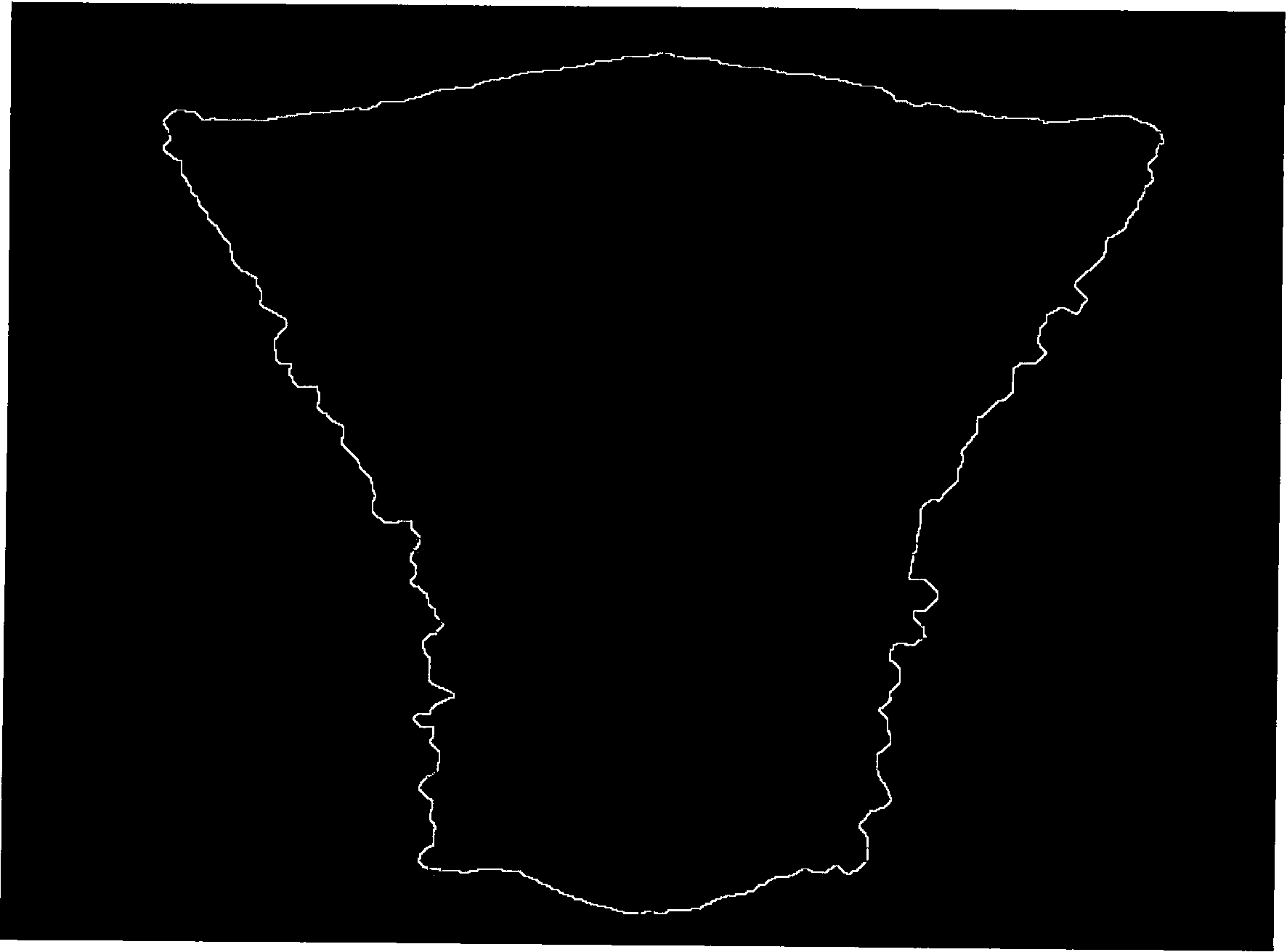

[0031] 1. Process the joint image, extract the joint contour, and binarize the joint contour image, the value of the contour point is 1, and the value of other points is 0. figure 1 Schematic diagram of a welded joint.

[0032] 2. Use the depth-first search method to obtain the burr-free connected contour in the joint image, and obtain the coordinates of the contour points, and then discretize the contour:

[0033] 2.1 Scan the binarized contour image pixels in step 1 from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com