Substrate panel

A substrate and panel technology, applied to electrical components, electrical solid devices, circuits, etc., can solve problems such as wire bonding failure, poor plating quality, internal circuit damage, etc., to improve the average dispersion of current, avoid uneven current density, The effect of protecting the internal circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

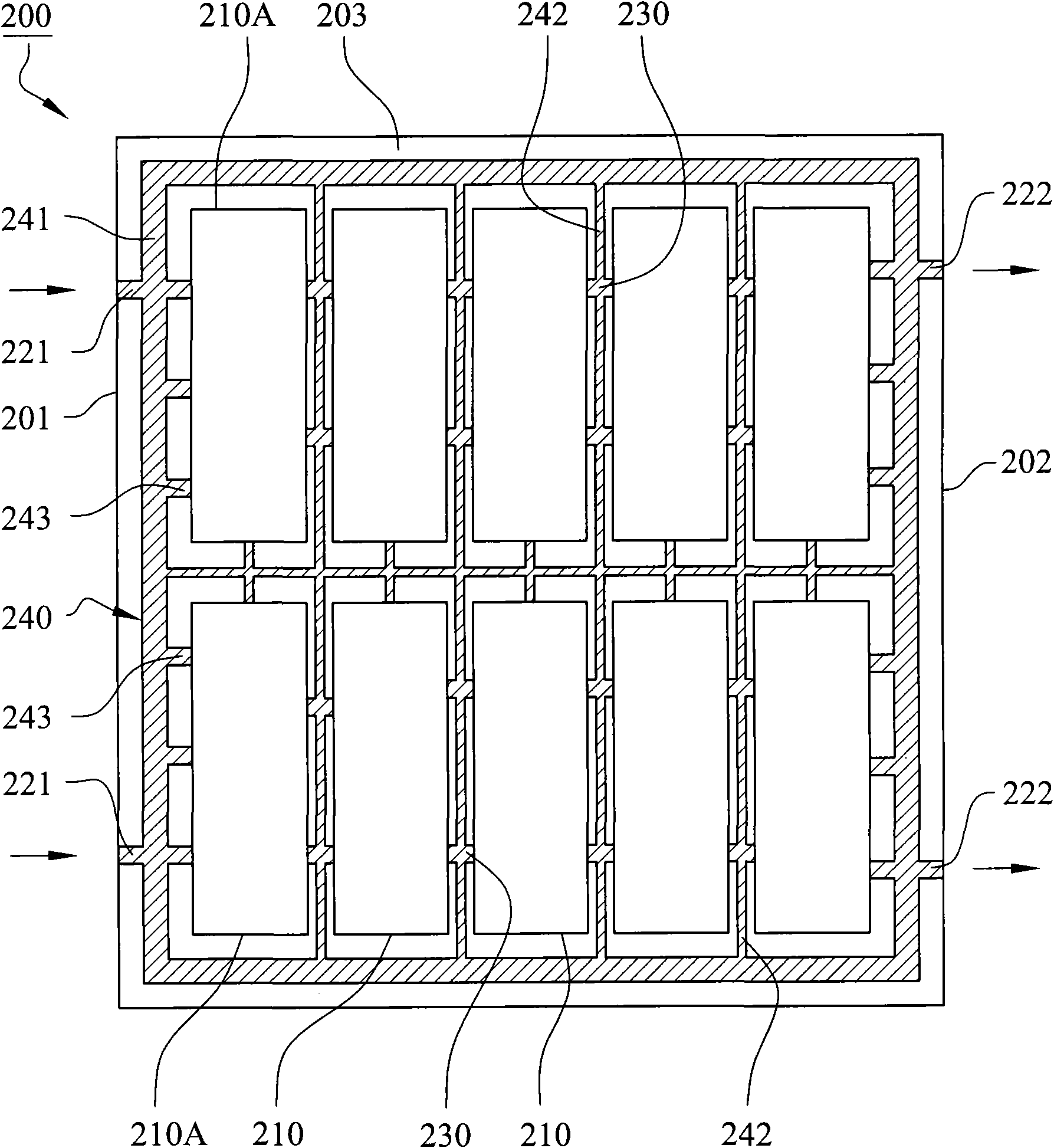

[0040] According to a specific embodiment of the present invention, a substrate panel is illustrated in figure 2 The schematic diagram of the top view and Figure 4A A schematic diagram of a partial cross-section.

[0041] The substrate panel 200 mainly includes two or more substrate strips 210 , two or more electroplating buses 221 and 222 , two or more electroplating serial lines 230 and a current input gate buffer 240 . Usually, the substrate panel 200 can be a large-sized printed circuit board, and the ratio of the long side to the wide side is approximately equal or not more than twice, such as 1:1, 4:3 or 16:10, etc., and is in the form of a panel form.

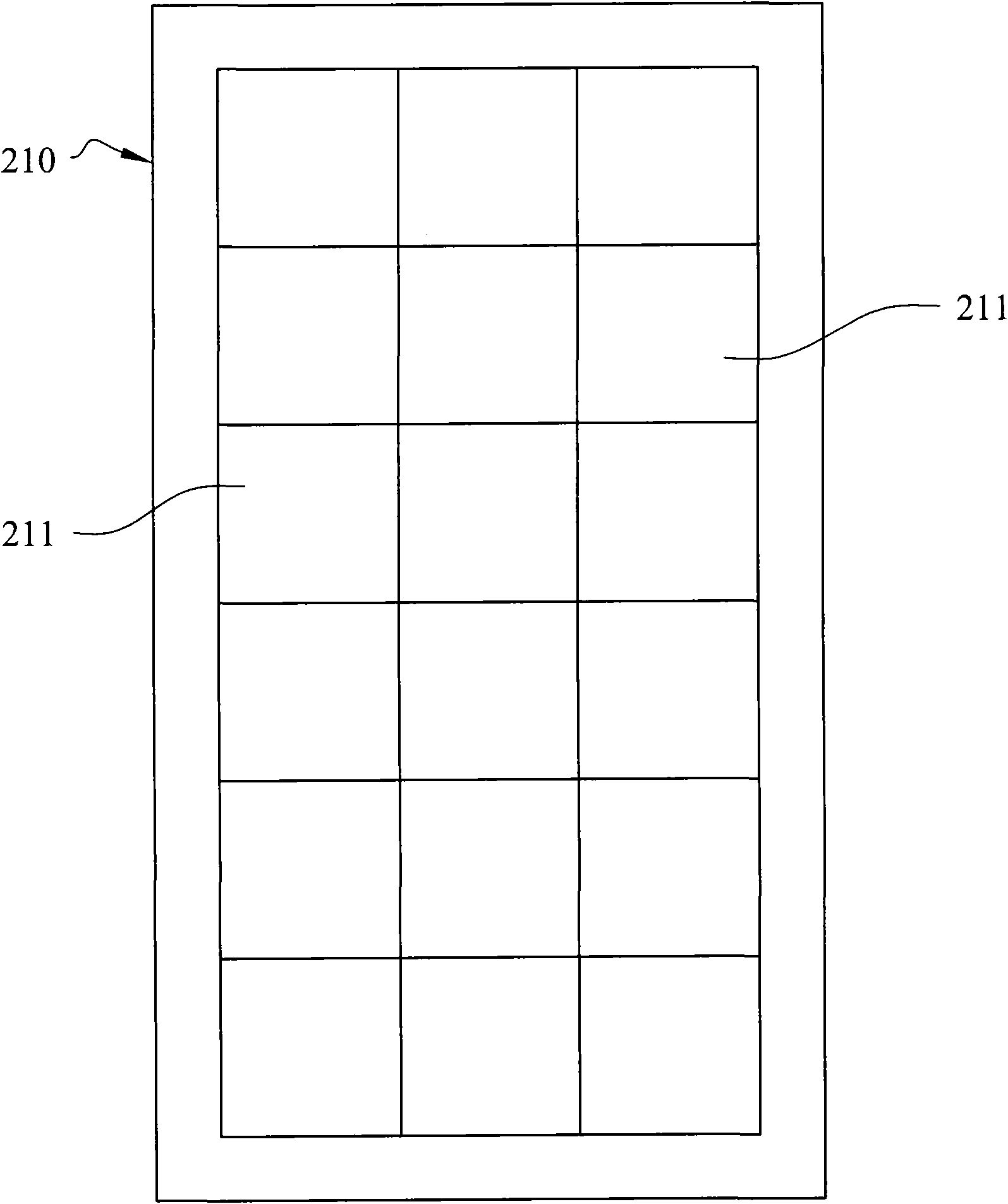

[0042] The substrate strips 210 are arranged in an array on the substrate panel 200 . like image 3 As shown, each substrate bar 210 contains two or more substrate units 211 arranged in an array, and each substrate unit 211 can be used as a chip carrier of a semiconductor package / combined structure, and two or more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com