Combustion engine with a motor brake device

一种发动机制动、内燃机的技术,应用在发动机控制、发动机元件、机器/发动机等方向,能够解决没有保证气体交换、阀门没有完全闭合、排气阀啪嗒噪声等问题,达到安全和有效安装和运行、节省位置空间、啪嗒噪声降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

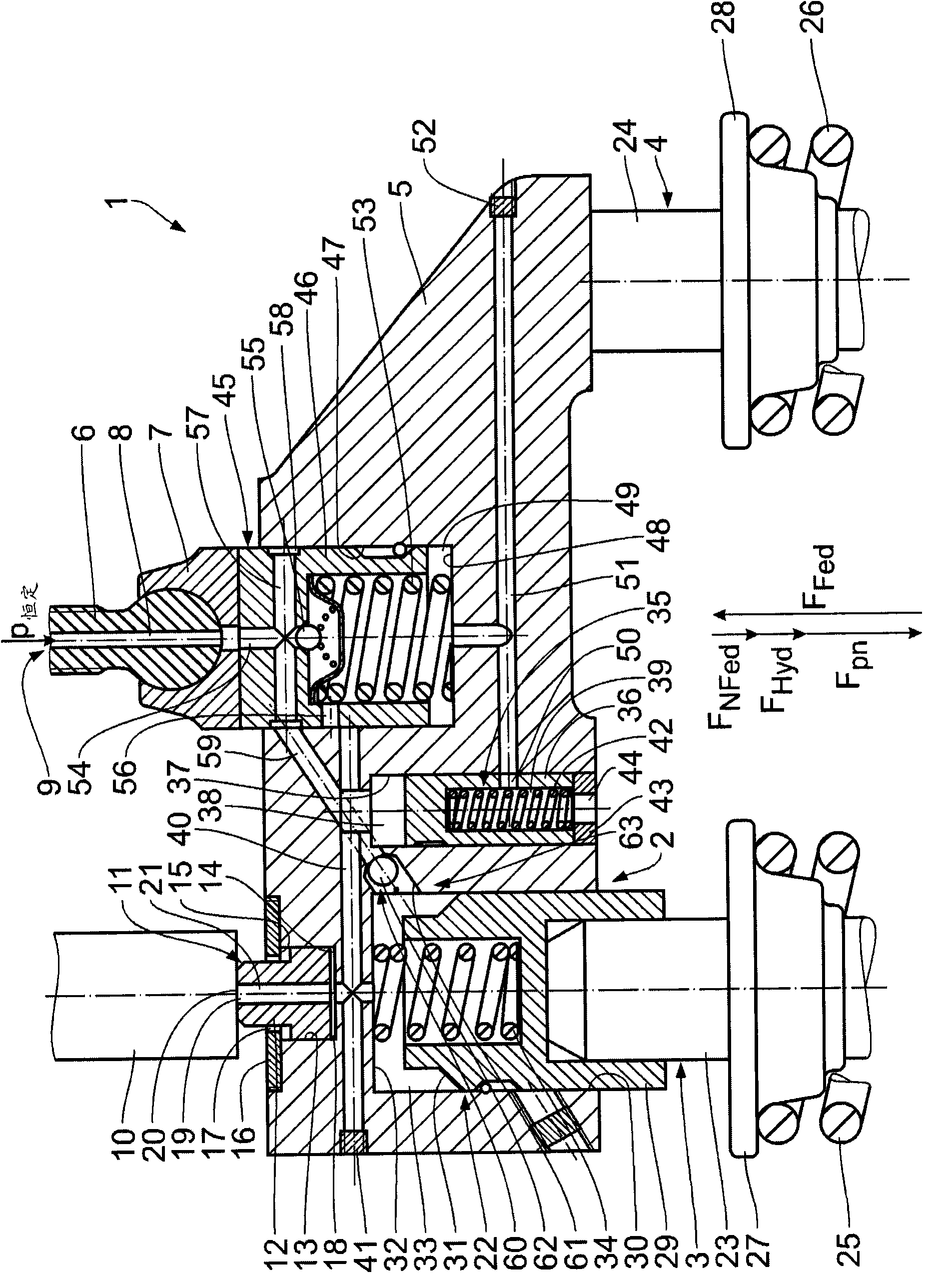

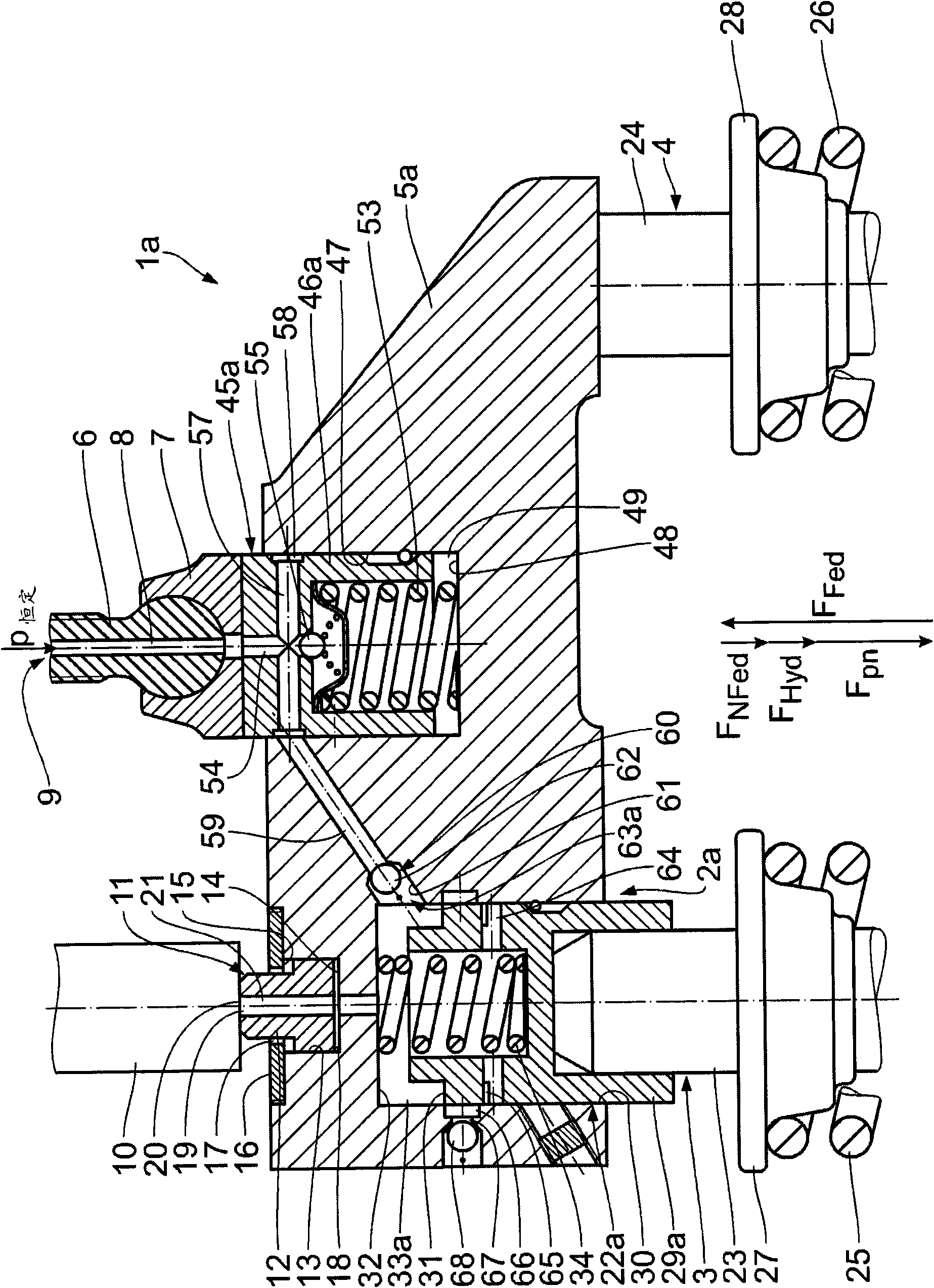

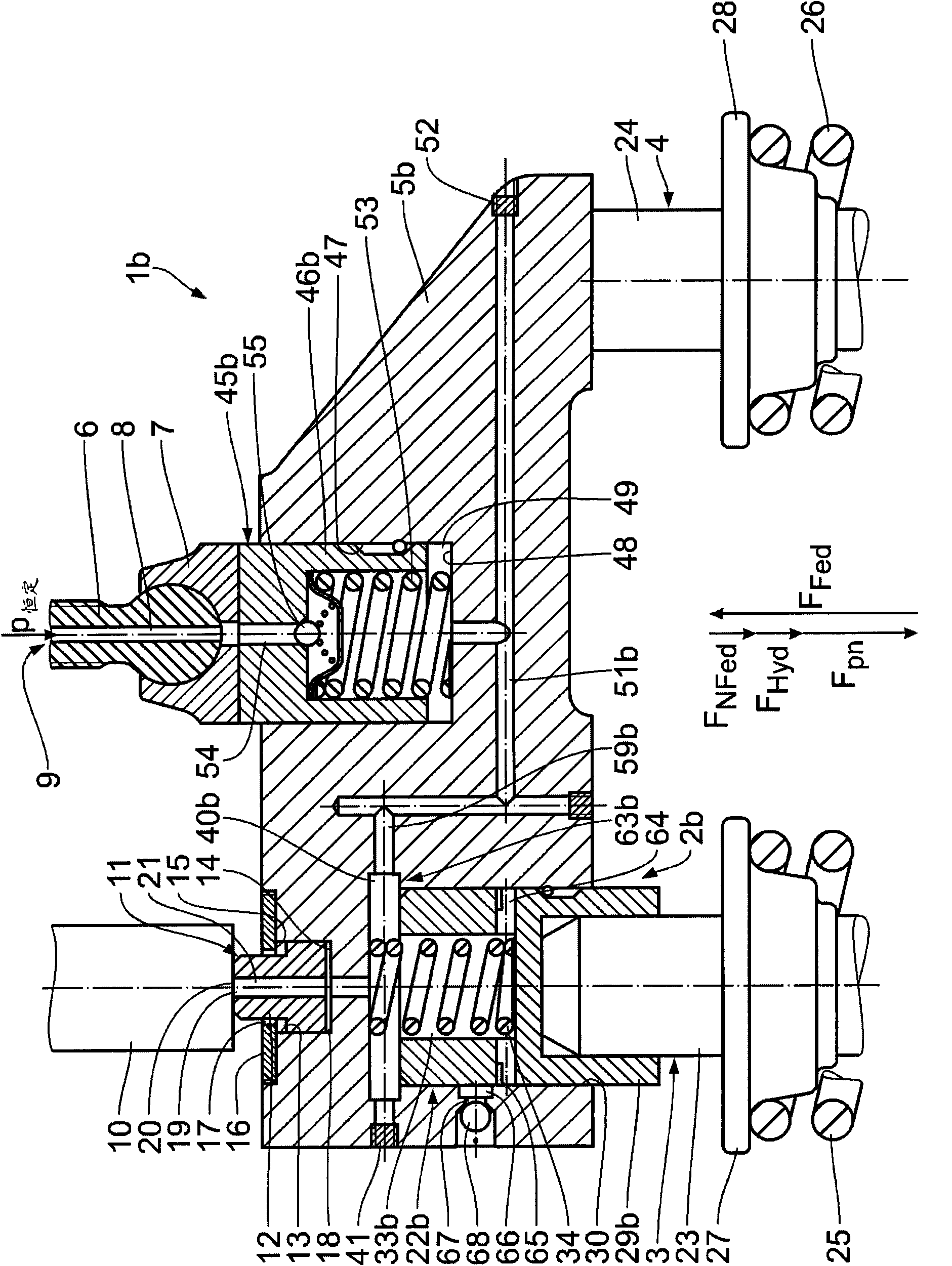

[0027] Below with the help of figure 1 A first embodiment of the present invention will be described. An internal combustion engine 1 provided with an engine braking device 2 has a plurality of figure 1 The cylinders, not shown, each delimit a combustion chamber. Air or an air-fuel mixture can be supplied to each of the fuel chambers by means of at least one intake valve. In addition, each fuel chamber has two exhaust valves 3 and 4 , by means of which exhaust gas can be discharged into the exhaust tract. Exhaust valves 3 and 4 can be activated and actuated mechanically by means of a common valve bridge 5 . The valve bridge 5 is part of the connecting mechanism that connects the exhaust valves 3 and 4 to the internal combustion engine 1 . figure 1 Camshaft not shown in the connection. In addition, the linkage mechanism includes a figure 1 A rocker that is supported in a swivel manner is not shown. The rocker acts on the valve bridge 5 via a partially shown contact pin 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com