Elastic-plastic beam dropping prevention spherical steel support seat

An elastic-plastic, anti-falling beam technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as bridge deck collapse, casualties, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

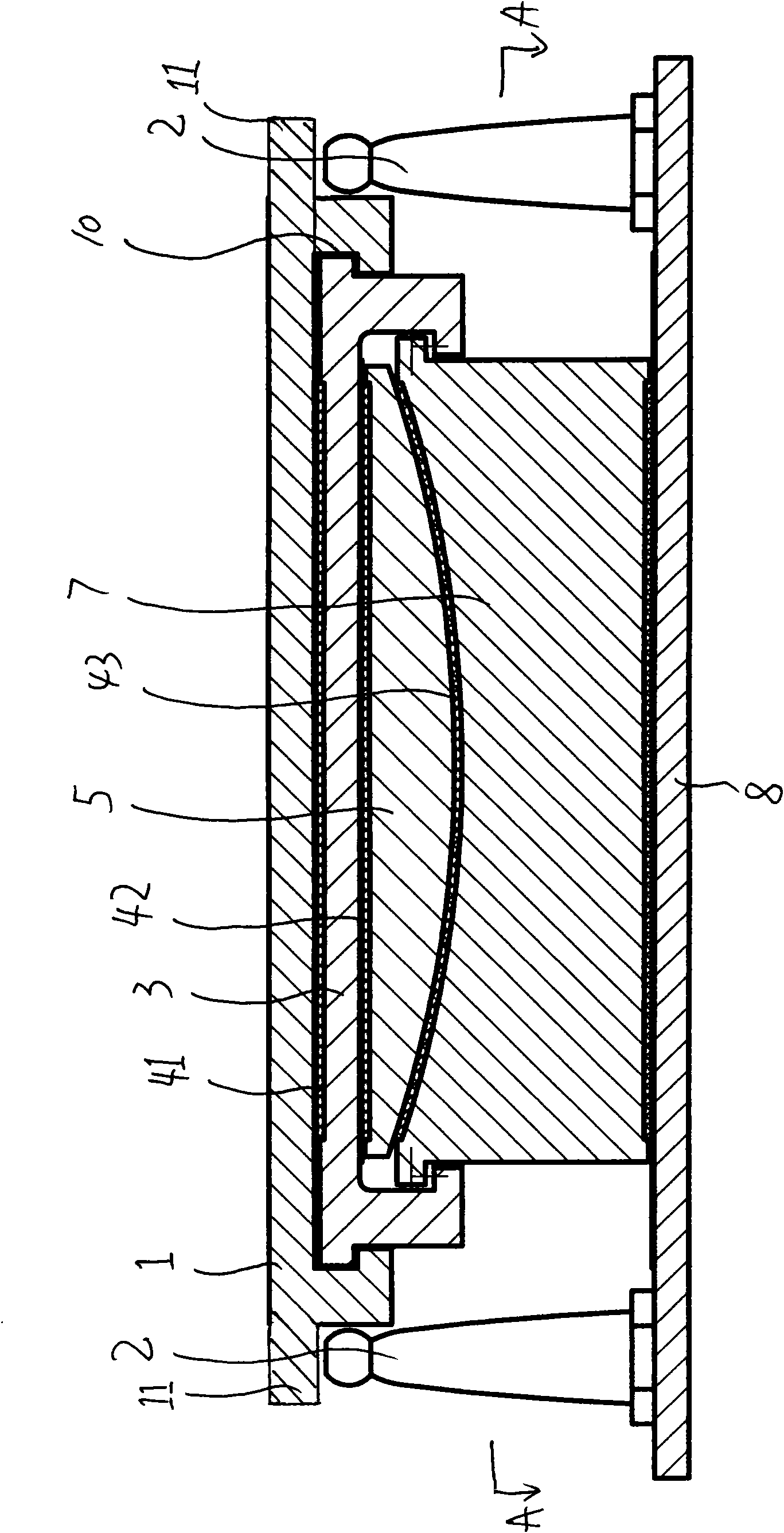

[0020] The structure of the elastic-plastic anti-drop beam spherical steel support provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] Such as figure 1 , figure 2 and Figure 4 As shown, the elastic-plastic anti-drop beam spherical steel bearing includes an upper slide plate 1, a first plane PTFE plate 41, an upper support plate 3, a second plane PTFE plate 42, and a ball core 5 arranged in sequence from top to bottom. , Spherical PTFE plate 43, base 7, base plate 8, the first slideway 10 along the free movement direction of the support is provided below the upper slide plate 1, the edge of the upper support plate 3 is snapped into the first slideway 10, the upper The slide plate 1 can move back and forth along the first slideway 10 relative to the upper support plate 3 . Shear pins 9 are provided at the four corners of the base 7 and the bottom plate 8 . On the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com