Method for processing cultivation net cage or passive small-sized high-performance head rope for fishing gear

A small-sized, high-performance technology, applied in the fields of application, fish farming, melt spinning, etc., can solve the problems of loss of fishermen or farmers, ship crashes, damages, etc., to improve the catch rate, improve safety, The effect of improving application adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

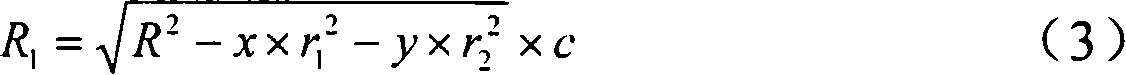

[0006] Embodiment 1: A kind of breeding cage or passive fishing gear with a diameter of φ5.0mm uses a small-sized high-performance mesh. The processing method consists of a luminescent yarn processing method, a marking yarn processing method, a nylon yarn processing method, a strand-making method and a mesh-making method. Composition, the specific implementation method is as follows:

[0007]Processing method of luminescent yarn: clean the mixer, mix luminescent pigment (such as PLO-7C luminescent pigment or RR-7 luminescent pigment), dry HDPE 5000S resin produced by Yangzi Petrochemical (melt index is 0.9g / 10min, if HDPE If the 5000S resin is damp, it should be dried in an oven or under sunlight before use), T30S PP resin produced by Daqing Petrochemical (melt index is 2.1-3.9g / 10min), additives (such as turpentine or white oil) Screening treatment is carried out to remove the main impurities that may be mixed in the raw materials, so as to ensure the normal drawing and reduc...

Embodiment 2

[0048] Embodiment 2: A kind of breeding net cage or passive fishing gear with a diameter D of 10.0mm is used. The processing method includes the processing method of luminous yarn, the processing method of marking yarn, the processing method of nylon yarn, the method of making strands and the method of making the mesh. Method steps.

[0049] Luminous yarn processing method: According to the luminous yarn processing method in Example 1, a PP / PE alloy luminous filament with good comprehensive performance (diameter 0.20mm, linear density 360dtex, breaking strength greater than 6.00cN / dtex, and elongation at break 11~ 22%, its softness and operability are better, and it can emit yellow-green or bright red fluorescence in the dark after being illuminated); the twisting machine twists 12 PP / PE alloy luminescent wires according to the twist of 98T / m Use the same twisting tension to form a luminous yarn (diameter 1.30mm) with a twist direction of "Z".

[0050] Marking yarn processing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com