Method for preparing ultralight water by isotope distillation

An ultra-light water and isotope technology, applied in the field of isotope distillation, can solve the problems of ultra-light water not suitable for drinking, shortening the equilibrium time, difficulty in safe production, etc., and achieve the effect of improving the isotope separation effect, shortening the separation time, and shortening the steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

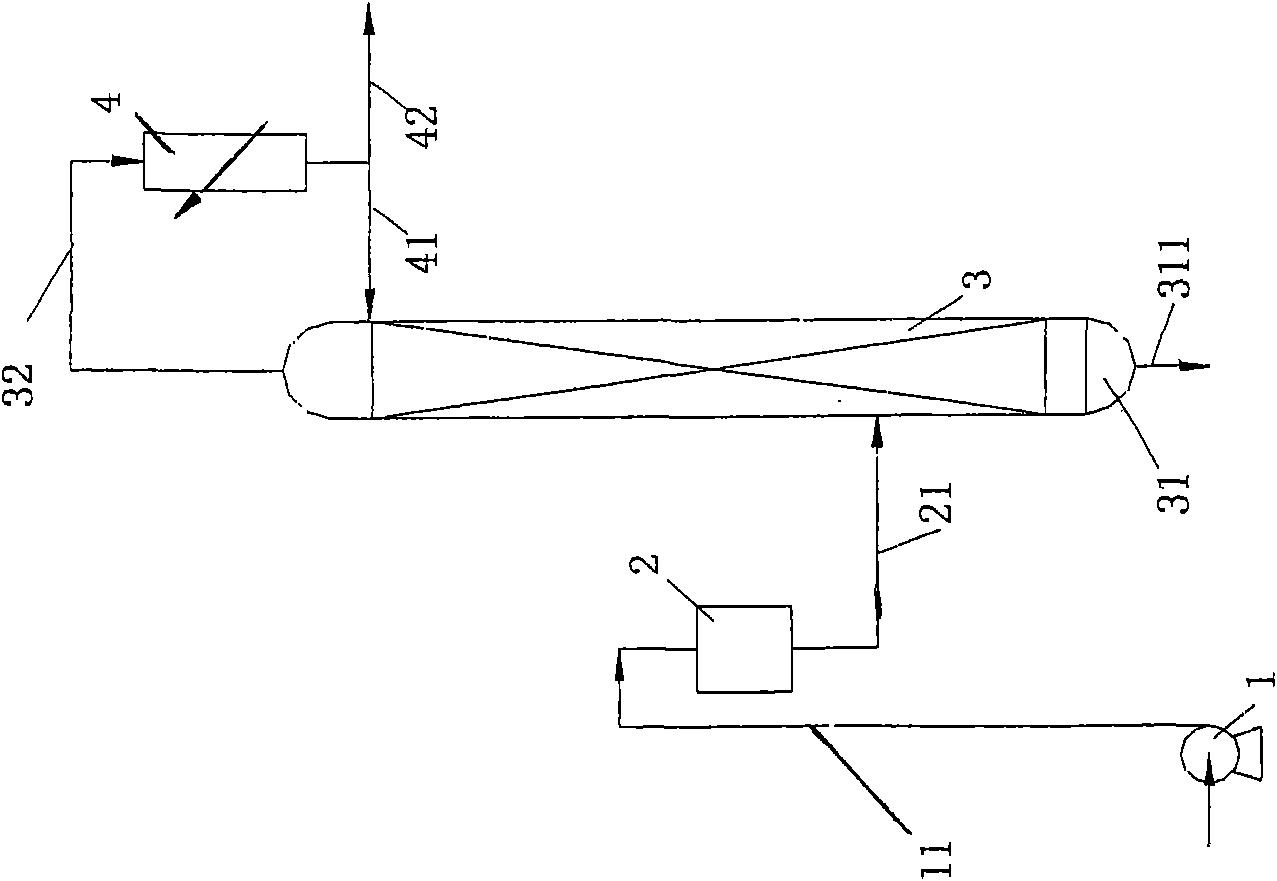

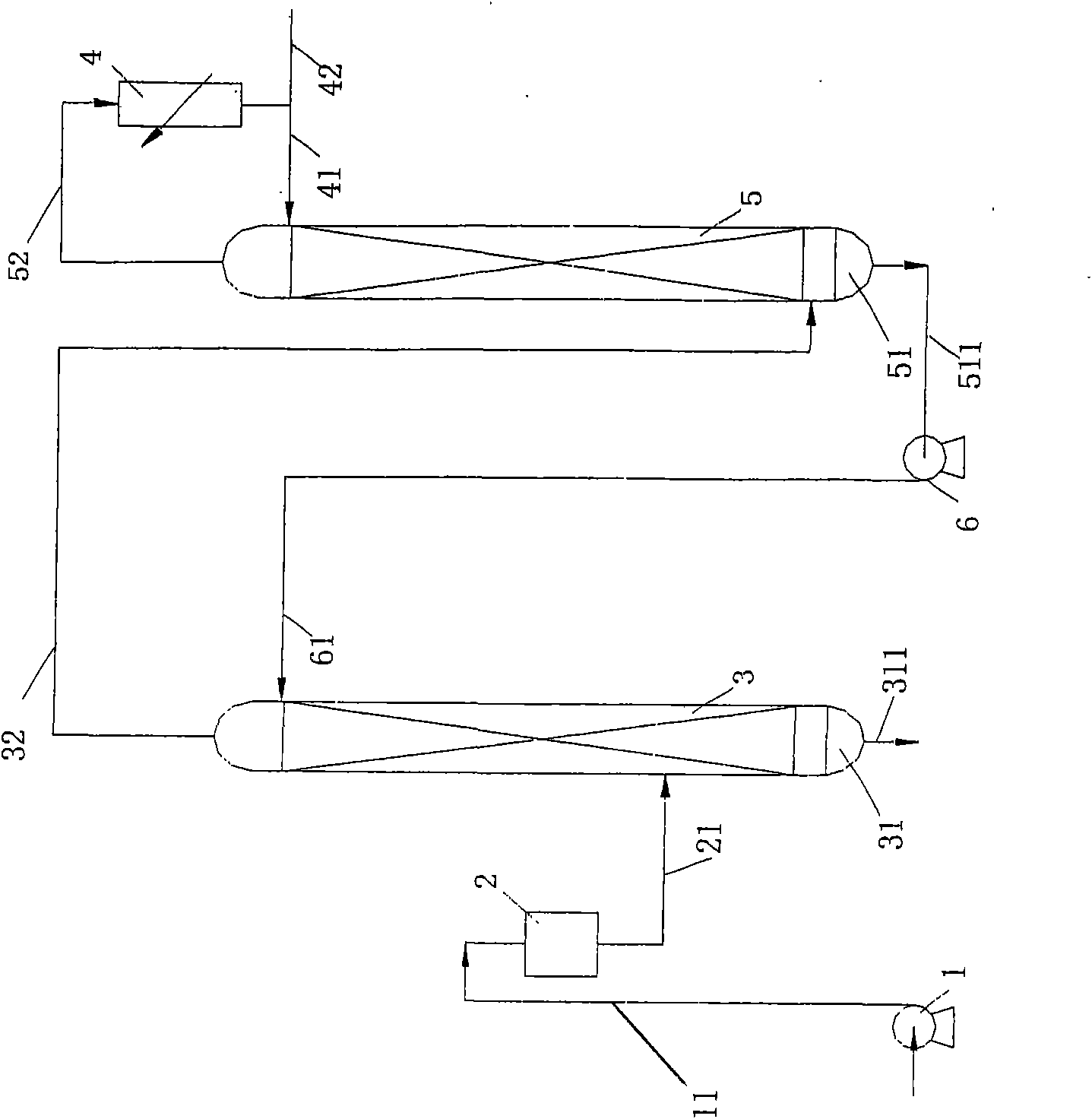

[0030] please see figure 2 , taking the preparation of ultra-light water with a deuterium content of 25ppm as an example, the specific steps are as follows:

[0031] A) produce purified water, with embodiment 1;

[0032] B) Prepare ultra-light water, please combine figure 2 , figure 2 The isotope separation device shown is two rectification towers connected in series. Since there are two rectification towers, the applicant calls it a two-stage process. The inner diameters of the two towers are 0.85m and 0.75m respectively, and they are filled with CY700 type Wire mesh corrugated packing is made of phosphor bronze. The net height of each tower packing is 12m. The feed inlet is at the place 4m away from the bottom of the first rectification tower 3. The theoretical plate number of the two towers is 163. currently by figure 2 Take the position shown as an example. The first rectification tower 3 is the rectification tower on the left with an inner diameter of 0.85m and a ...

Embodiment 3

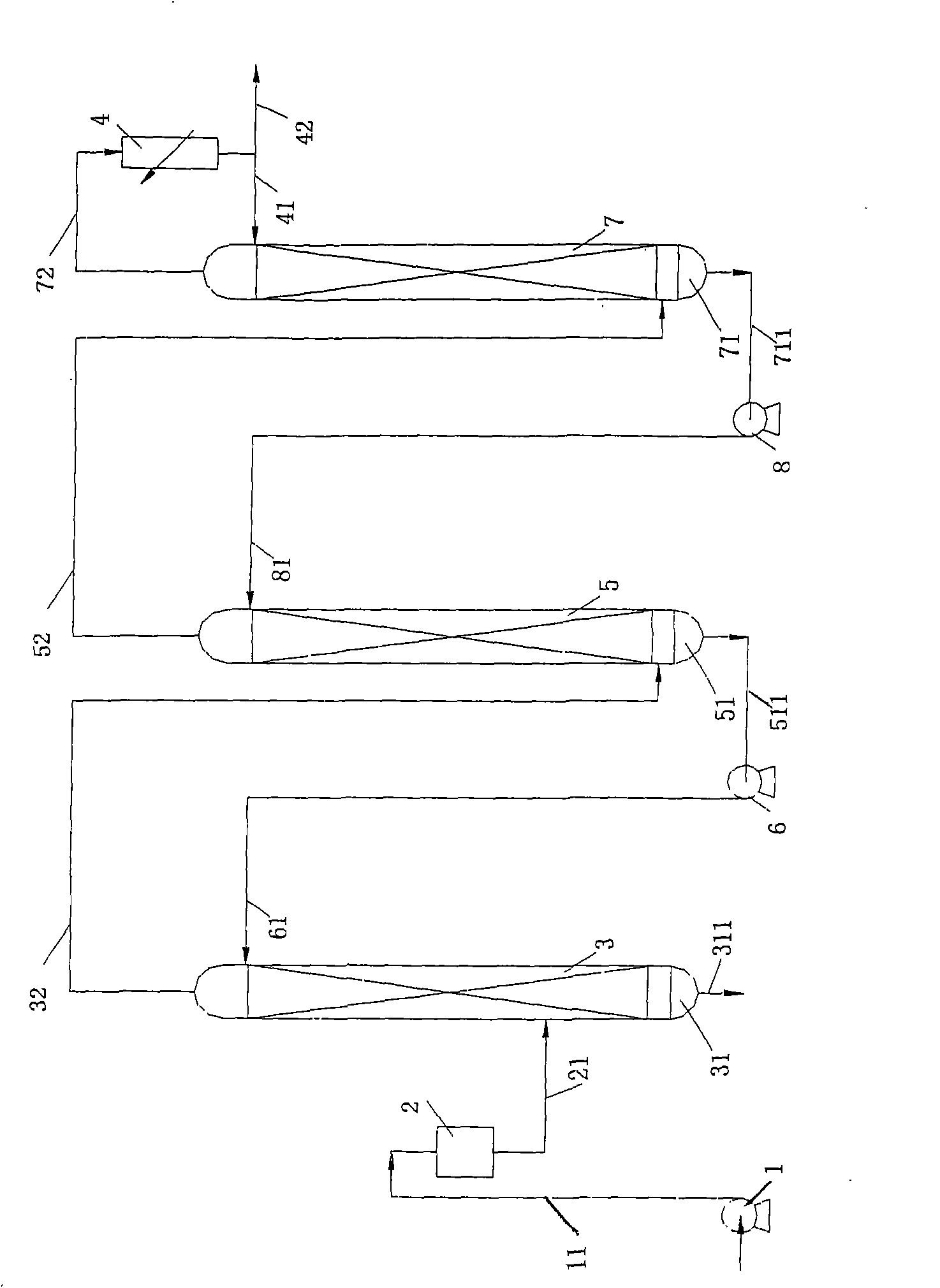

[0035] please see image 3 , taking the preparation of ultra-light water with a deuterium content of 1ppm as an example, the specific steps are as follows:

[0036] A) produce purified water, with embodiment 1;

[0037] B) Prepare ultra-light water, please combine image 3 , image 3 The schematic isotope separation device is three rectifying towers connected in series. Since there are three rectifying towers, the applicant calls it a three-stage flow process. The three rectifying towers are the first, second and third rectifying towers 3, The inner diameters of 5 and 7 are 0.32m, 0.3m and 0.24m respectively, and each is filled with CY700 type phosphor bronze wire mesh corrugated packing. At the bottom 4m of the tower, the relevant parameters of the first, second and third rectification towers 3, 5 and 7 are shown in the table below:

[0038] parameter name

The first distillation column 3

The second distillation tower 5

The third distillation tower 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com