Normally conductive electromagnetic levitation track inspection vehicle

A kind of inspection vehicle and maglev technology, which is applied in electric vehicles, electric vehicle charging technology, railway car body and other directions, can solve the problems of not adapting to the structural requirements of the track inspection vehicle, the equipment interlayer cannot be realized, and the inspection vehicle cannot be integrated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

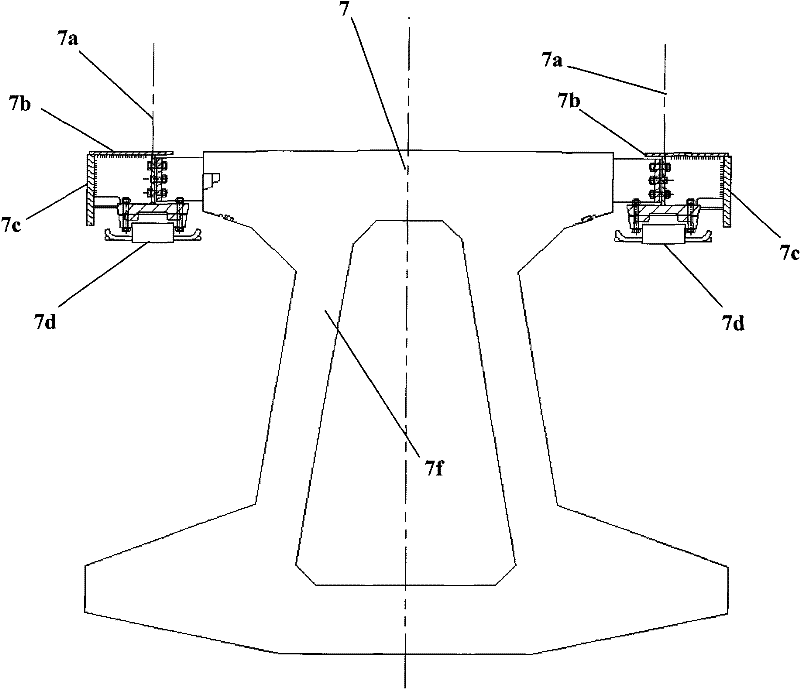

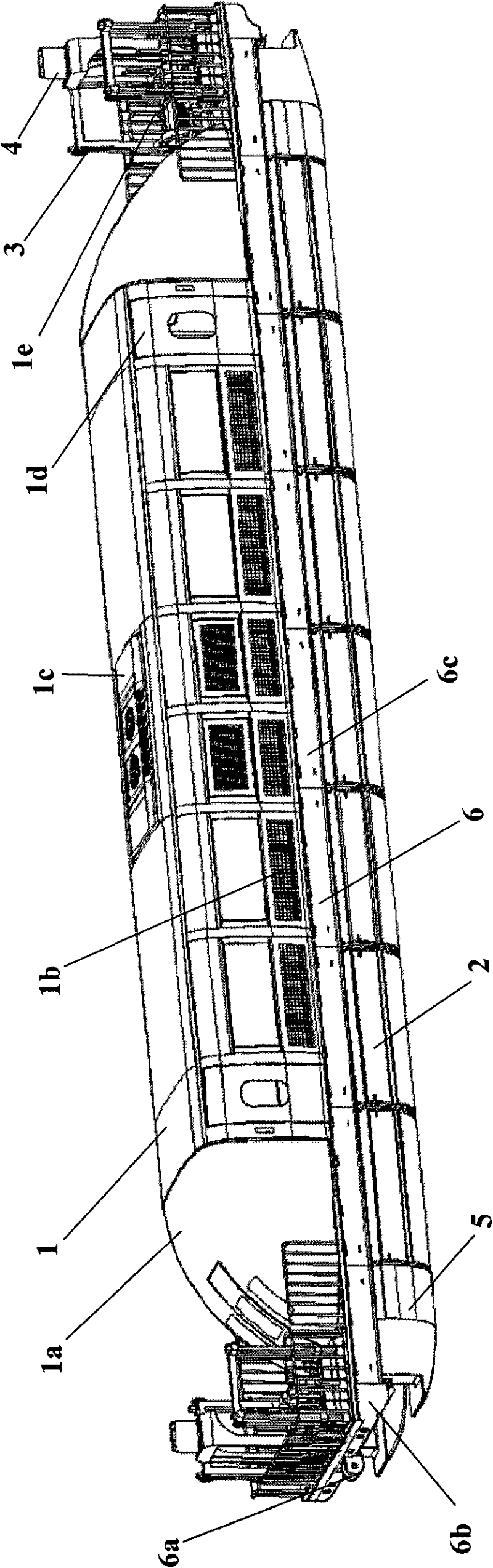

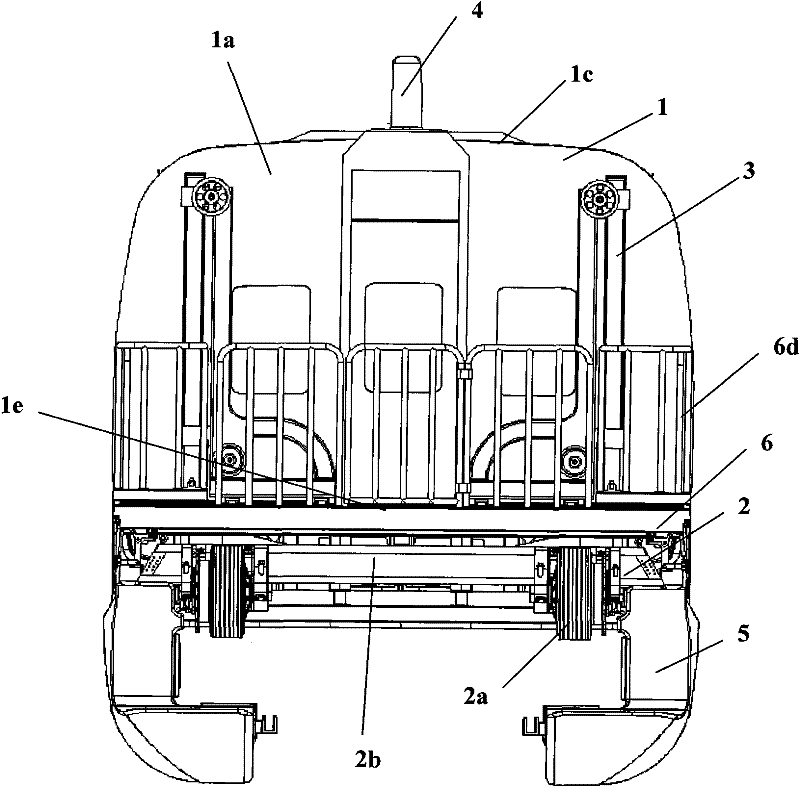

[0063] based on the following Figure 1 to Figure 5 , to describe in detail the preferred embodiments of the present invention.

[0064] like figure 2 As shown, the present invention provides a conventional electromagnetic levitation track inspection car, which includes a frame car body and a running structure 2 arranged at the bottom of the frame car body;

[0065] like figure 2 As shown, the compartment structure 1 is shorter than that of ordinary high-speed passenger maglev trains. The aluminum alloy extruded profiles are used to form a frame structure, and the position of the compartment side door 1d is moved inward, maintaining the setting of four compartment side doors 1d. A headstock 1a with a front door and two operating platforms 1e are provided. The length of the headstock 1a is shortened, leaving a space for the operating platform 1e. Four lifting maintenance platforms 3 are arranged in the space of the operating platform 1e. The light weight and sufficient str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com