Blow molding machine with air conditioning

A molding machine and air-conditioning technology, applied in air-conditioning systems, space heating and ventilation, heating methods, etc., can solve problems such as cost increase and change in bottle measurement value, achieve stable measurement value, prevent the deterioration of the working environment, and stabilize production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, the present invention will be explained in further detail with the aid of illustrated embodiments.

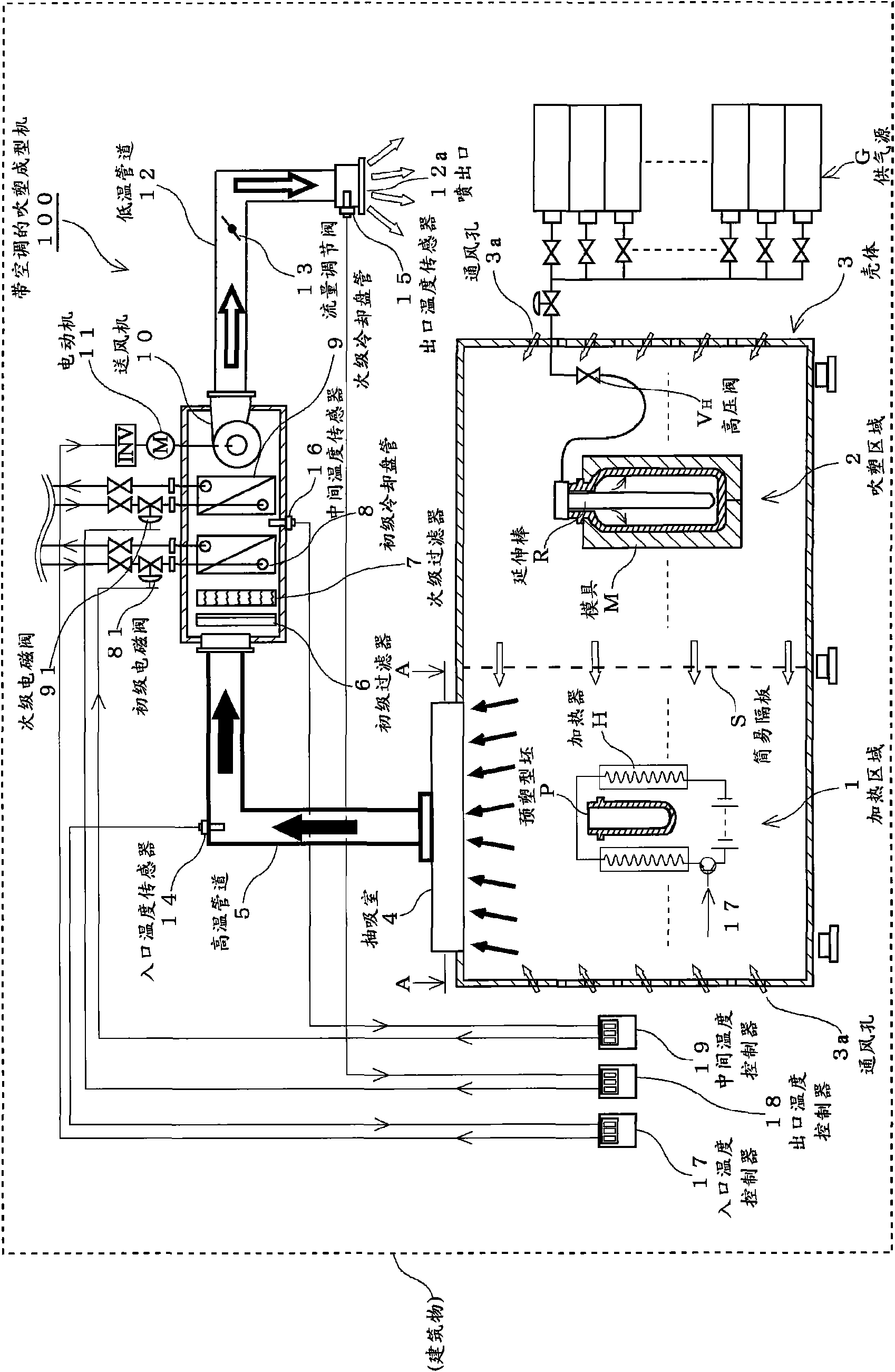

[0037] figure 1 It is an explanatory diagram showing the configuration of the air-conditioned blow molding machine 100 of the present invention.

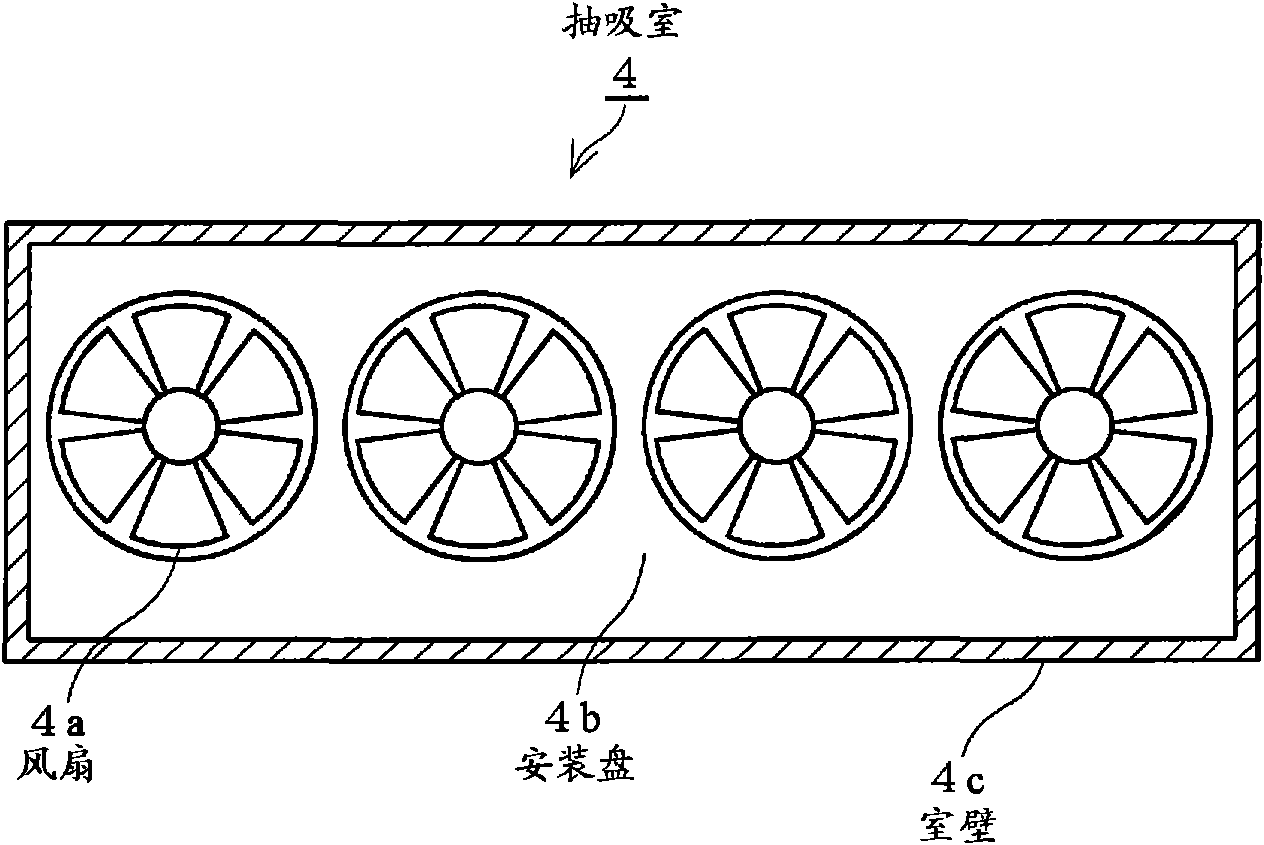

[0038] The structure of the air-conditioned blow molding machine 100 has: a heating zone 1, which preheats the preform P by means of a heater H; a blow molding zone 2, which installs the preheated preform P in Mold M and implements biaxial stretch blow molding with the aid of extension rods R and high pressure air; housing 3 covering these areas; suction chamber 4 that draws heated air from the heating zone 1; heating pumped by suction chamber 4 High temperature pipe 5 for air flow; coarse primary filter 6 for filtering the heated air; fine secondary filter 7 for filtering the heated air; primary cooling coil 8, which acts as the first cooling unit, flows from the heated air Cooling water that absorbs heat;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com