Wire-connecting mechanism for soft and hard cables of water pump

A cable and water pump technology, which is applied in the field of water pump cable connection, can solve the problems of poor insulation performance of the tape, easy pull-off of the connection, and easy leakage of electricity, etc., and achieve the effect of good insulation performance, easy disassembly, and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

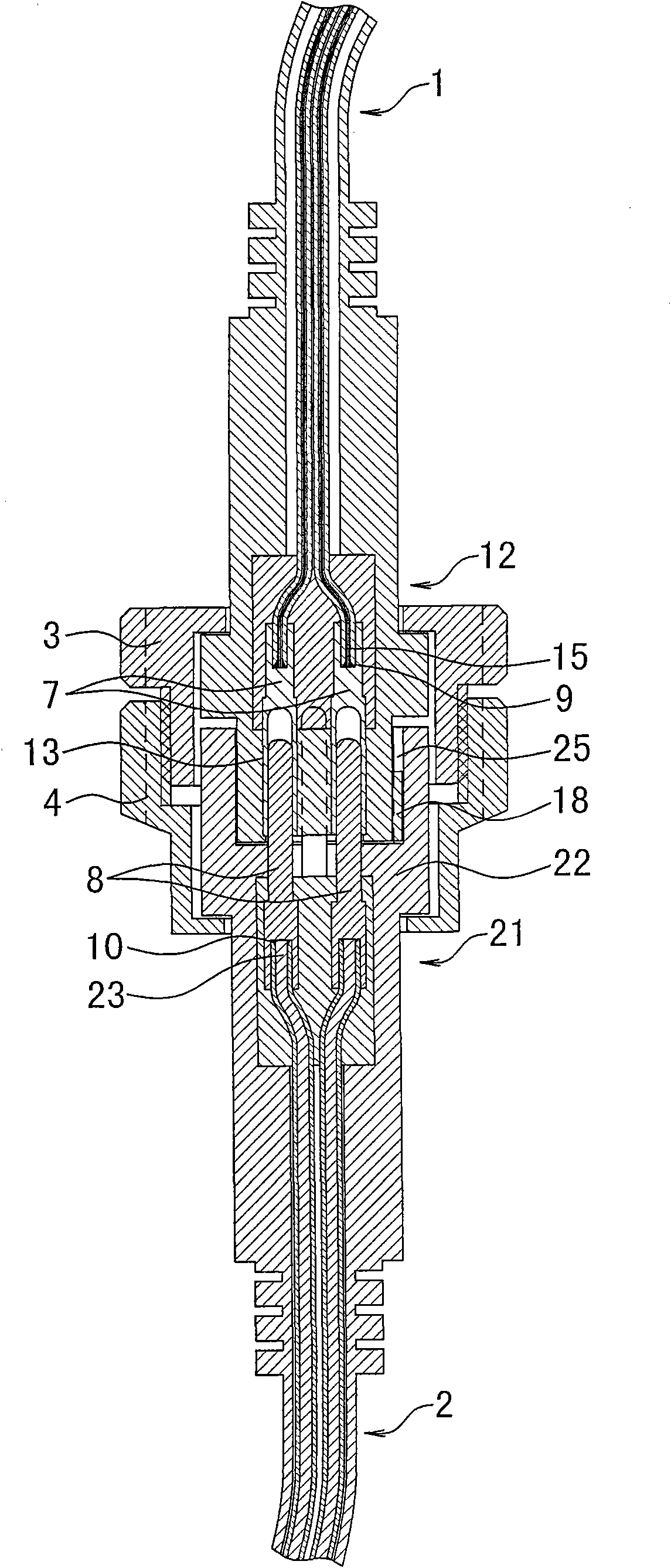

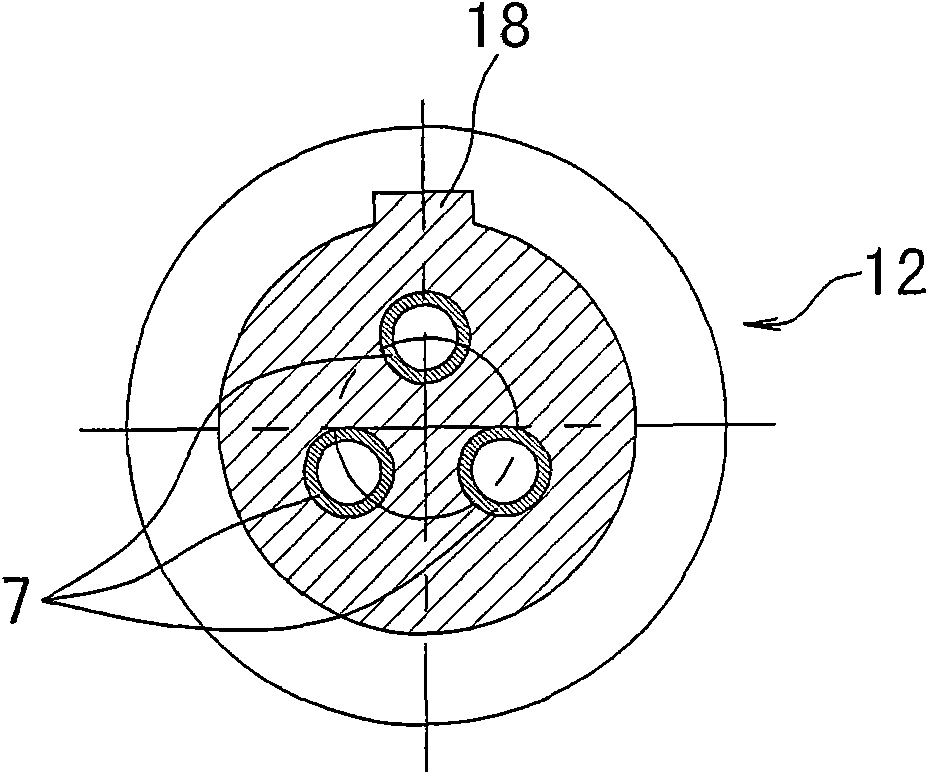

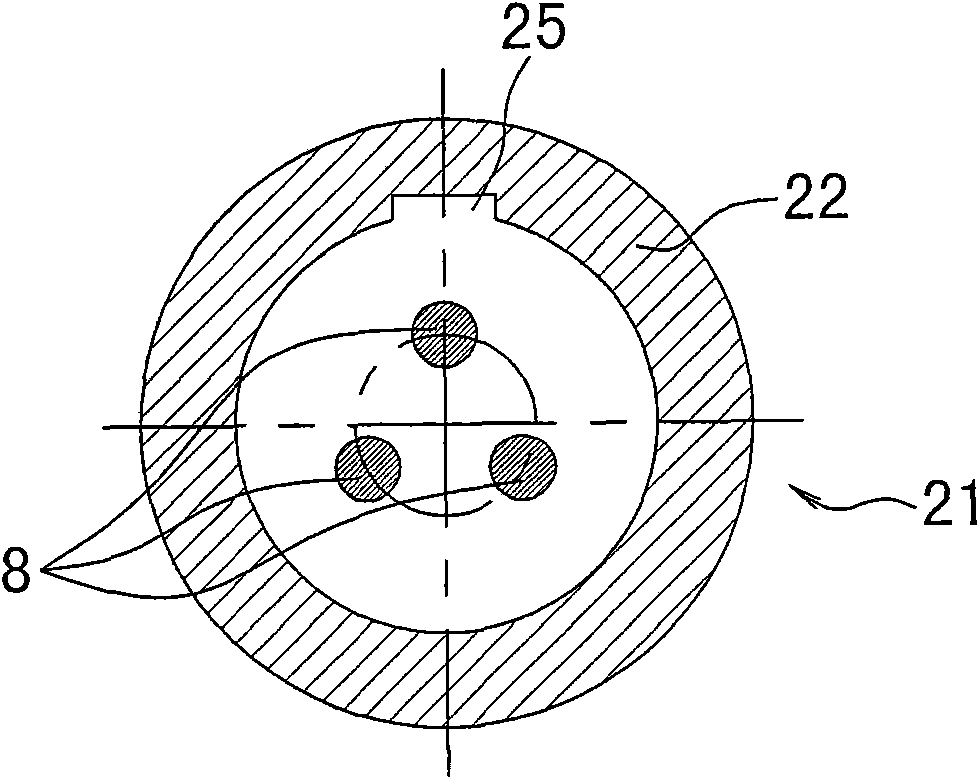

[0010] The invention discloses a water pump soft and hard cable connection mechanism, such as figure 1 As shown, it includes soft wire cables and hard wire cables. It is characterized in that the end of the soft wire cable 1 is formed with a rubber socket 12. The rubber socket includes a jack 13 and a soft wire head 15. A conductive female connector 7 is installed in the jack, which is electrically conductive. The female connector 7 is in contact with the soft wire head 15; a rubber plug 21 is formed at the end of the hard line cable 2, the plug 21 includes a sheath 22 and a hard wire head 23, and the hard wire head 23 is in contact with the conductive male connector 8, and conducts electricity. The male connector 8 is inserted into the conductive female connector 7 , and a fixing device is installed outside the socket 12 and the plug 21 . In this program, the end of the soft cable 1 is made into a socket 12, and the end of the hard cable 2 is made into a plug 21. In actual pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com