Discharge lamp

A technology for discharge lamps and discharge vessels, which is applied to discharge lamps, gas discharge lamps, high-pressure discharge lamps, etc., can solve the problem of electrode main body 1051 falling, and achieve the effects of preventing axis deviation, good bonding state, and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] use Figure 1 to Figure 7 Embodiments of the present invention will be described.

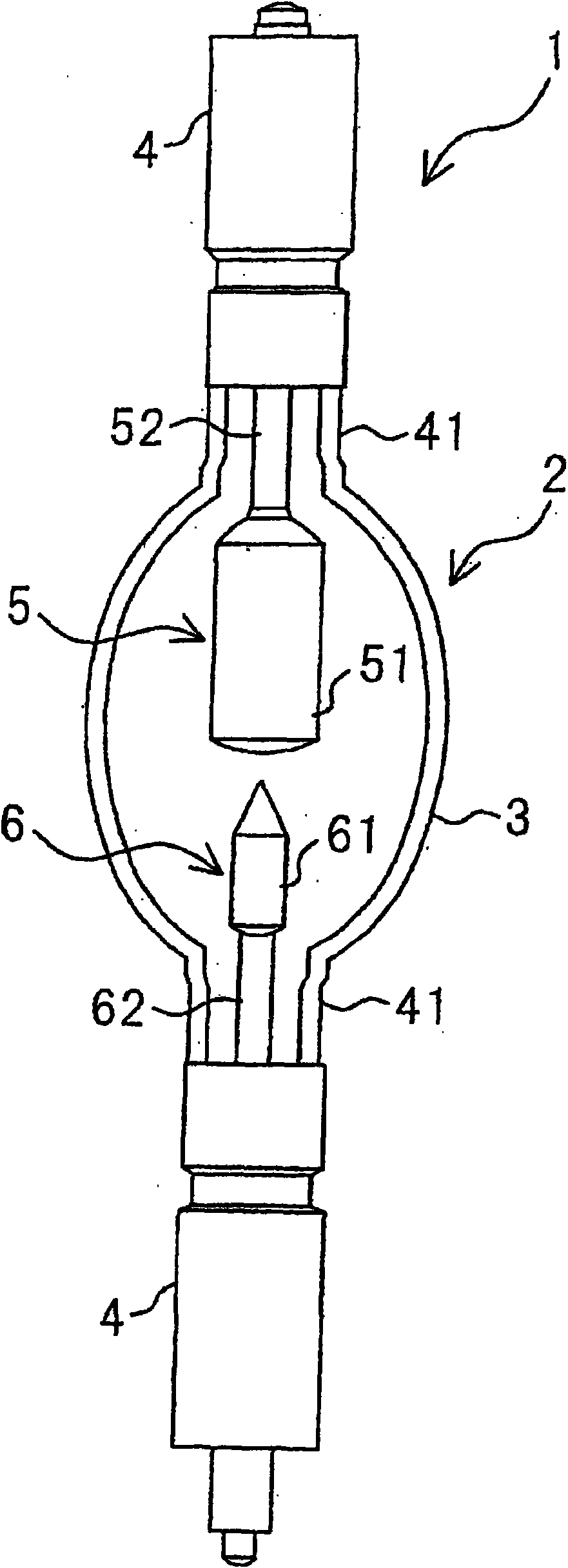

[0034] figure 1 It is a partial cross-sectional view showing the structure of the short-arc discharge lamp 1 according to the invention of the present embodiment.

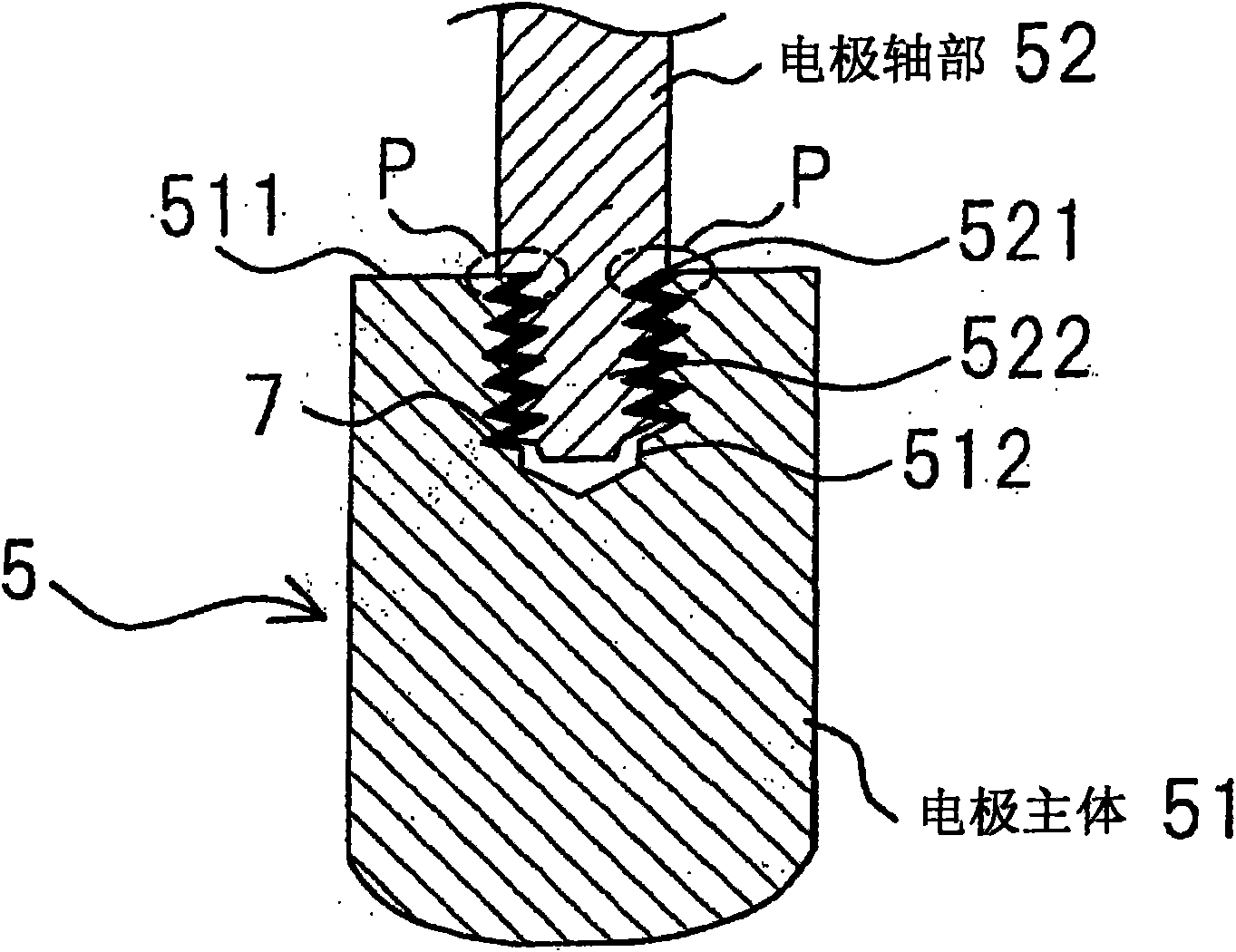

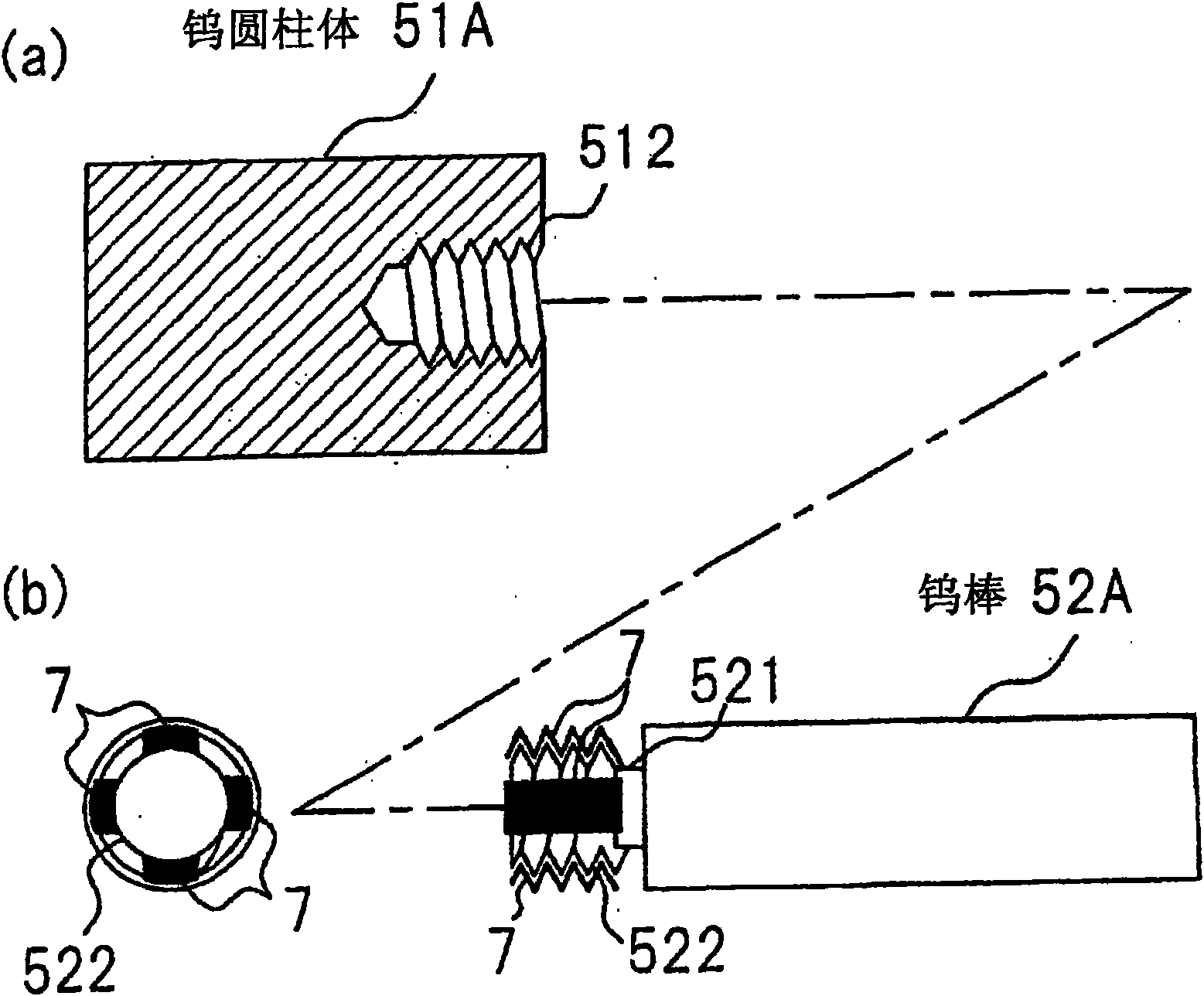

[0035] as it should figure 1 As shown, the discharge vessel 2 of the short-arc discharge lamp 1 is formed of quartz glass, and is composed of an elliptical luminous tube 3 and a cylindrical sealing tube 4 continuously extending from both ends of the luminous tube 3 to the outside. A portion of the sealing tube 4 where the arc tube 3 is continuous is formed with a reduced-diameter portion 41 in which a part of the sealing tube 4 has a reduced diameter. In the arc tube 3 of the discharge vessel 2, the anode 5 and the cathode 6 are arranged facing each other. The electrode main bodies 51, 61 of these electrodes 5, 6 are respectively made of tungsten, and are respectively fixedly supported by the front ends of columnar elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com