Tool used for assembling detection device and using method

A technology for assembling detection and detection devices, which is applied in the direction of biological testing, material inspection products, and analysis by making materials undergo chemical reactions. Efficient, tight lap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

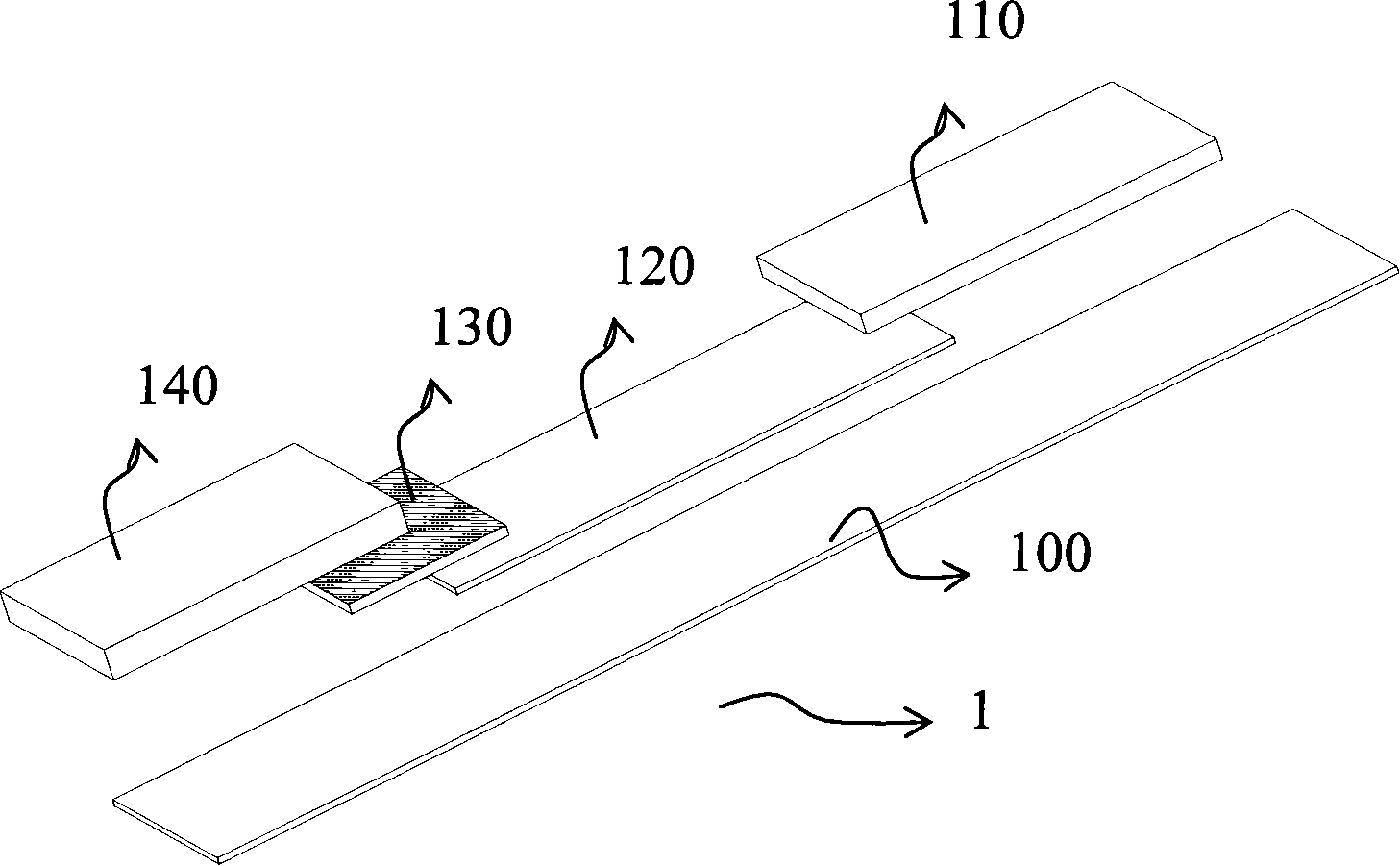

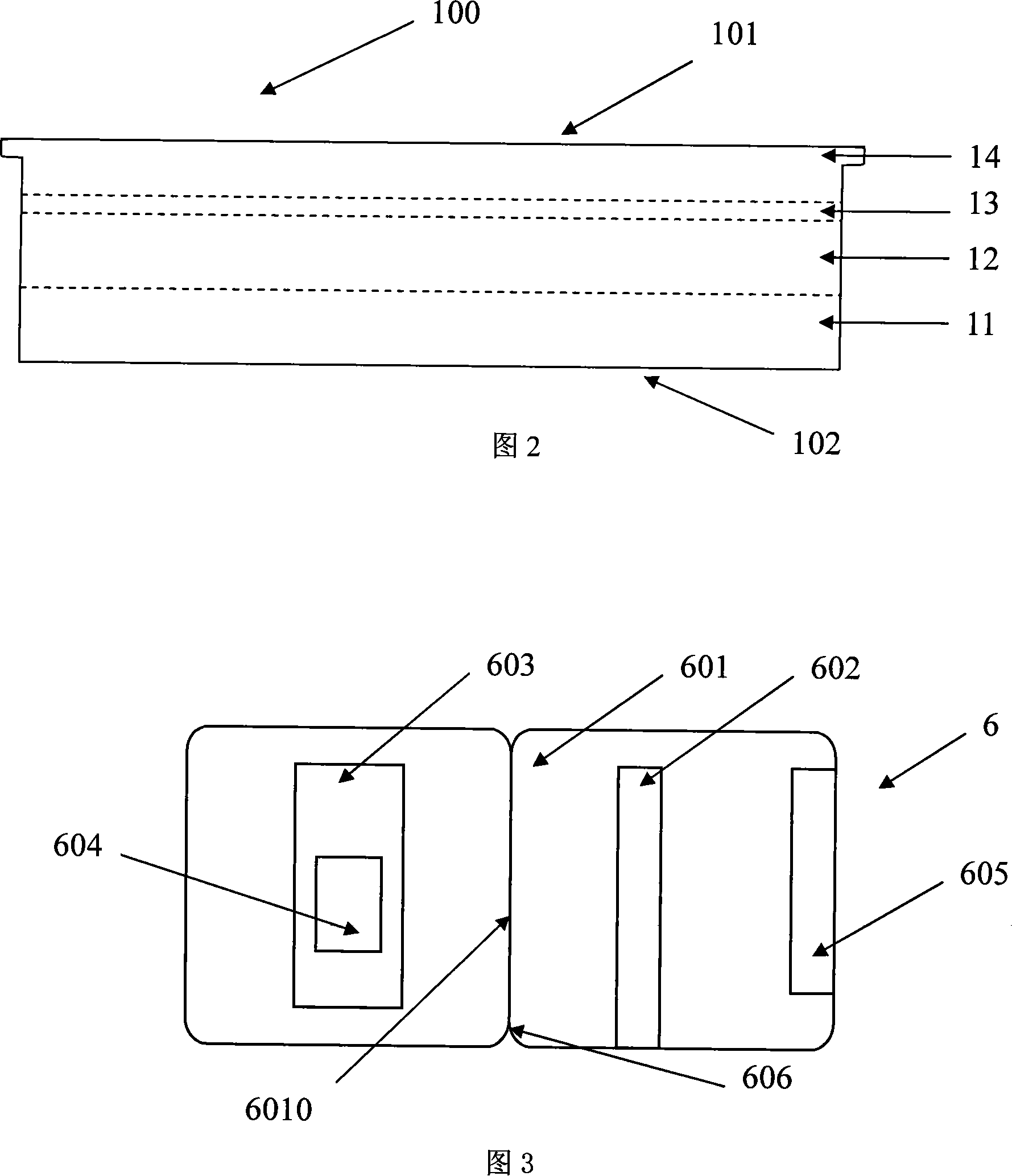

[0072] Embodiment 1: in this embodiment, what needs to be assembled is a reagent strip 1 with a length of 6 cm and a width of 0.4 cm. Such a large card 10 is provided: 20 cm in length and 6 cm in width, used for the assembly of the reagent strip 1, and finally cut into 50 evenly Strip reagent strip1. On the large card 10, the sample receiving area 14 is 18 mm wide, the marking area 13 is 8 mm wide, the detection area 12 is 19 mm wide, and the water-absorbing area 11 is 18 mm wide. The overlapping distance between each area is 1 mm. That is, the assembled reagent strip 1 has the following characteristics: the sample receiving pad 140 on the reagent strip 1 is 18 mm long and 4 mm wide, the marking pad 130 is 8 mm long and 4 mm wide, the nitrocellulose membrane is 19 mm long and 4 mm wide, and the absorbent pad is 18 mm long. 4mm wide. Such as Figure 4 The clamp 2 shown includes a bottom plate 201 , a first positioning plate 202 , a second positioning plate 203 and a positioni...

Embodiment 2

[0073] Embodiment 2: Taking the assembly of the reagent strip 1 for detection of malaria as an example, such a large card 10 is provided: 20 cm long and 8 cm wide, for the assembly of the reagent strip 1, and finally cut into 50 reagent strips 1 evenly. The reagent strip 1 includes a sample receiving area 14, a marking area 13, a detection area 12, a water absorption area 11 and a washing area. The reagent strip 1 is 8 cm long and 0.4 cm wide, the sample receiving area 14 is 25 mm long, the marking area 13 is 8 mm long, the detection area 12 is 18 mm long, and the water absorption area 11 is 32 mm long. The overlapping distance between the above areas is 1 mm. Part of the water-absorbing area 11 overlaps, the flushing area is 18 mm long, the distance between the downstream of the sprint area and the bottom of the big card is 2 mm, and the upstream distance of the water-absorbing area 11 is 10 mm. That is, the assembled reagent strip 1 has the following characteristics: the sam...

Embodiment 3

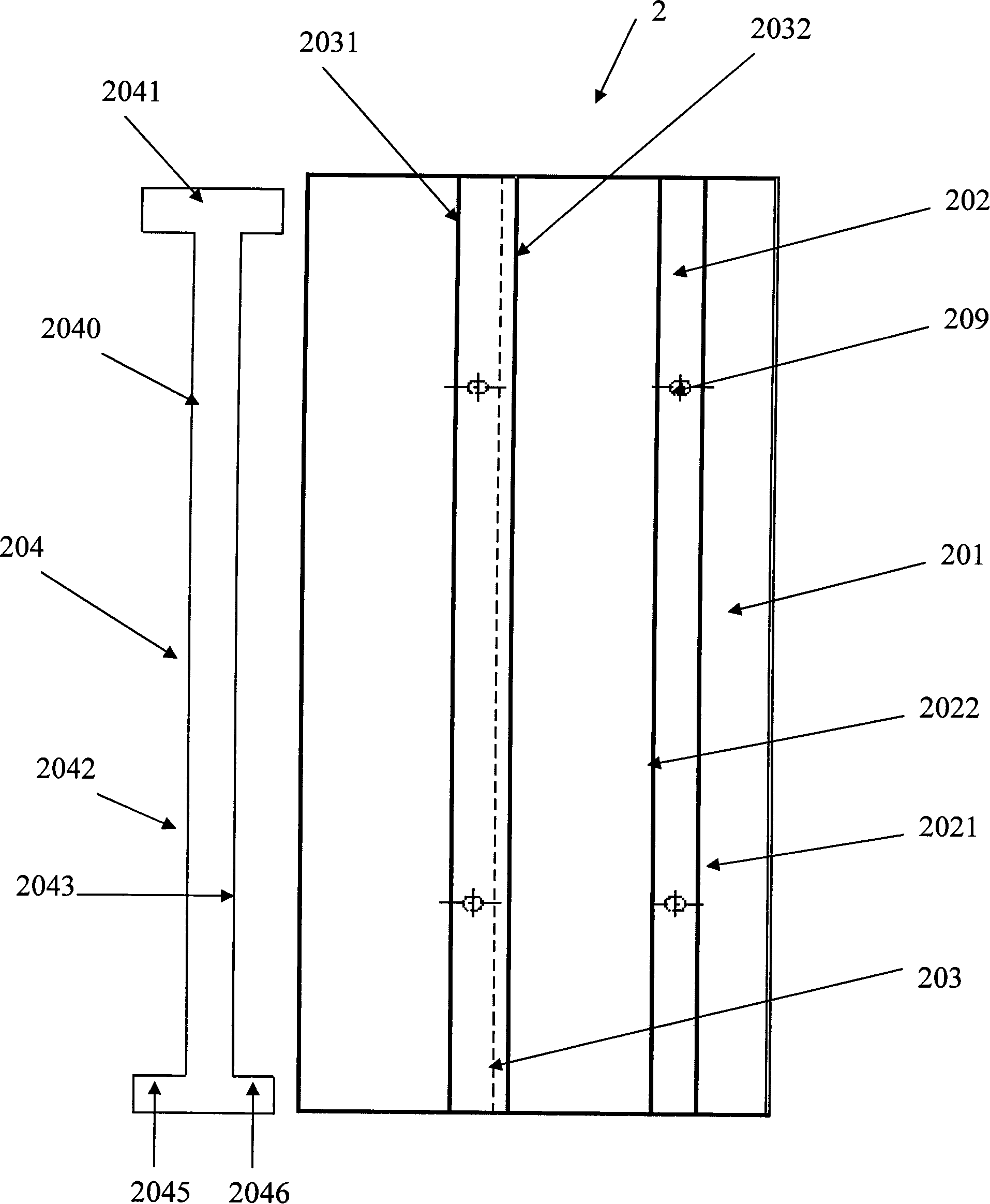

[0074] Embodiment 3: This embodiment takes the assembly of the detection card 6 as an example. The detection device is a card-type foldable device, including an assembled reagent strip 602 , a transparent sheet 603 and a self-adhesive 605 . The reagent strip 601 and the transparent sheet 603 are respectively located on symmetrical sides of the center line 6010 of the test card 6 , so that the test results on the reagent strip 602 can be displayed on the test result reading window 604 . The reagent strip 602 is used to detect influenza A+B. All components on the reagent strip 602 have been processed. The reagent strip is 6 cm long and 0.4 cm wide. The transparent sheet 603 is 5.5 cm long and 1 cm wide, and the self-adhesive 605 is 5 cm long and 0.8 cm wide. Such as image 3 As shown in the test card 6, Figure 7 with Figure 8The clamp 4 shown includes an upper positioning plate 401 and a lower positioning plate 402 , and the positioning plates are connected together by scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com