A non-explosive metal pipe annular cutting device

A technology for cutting devices and metal pipes, which is applied in wellbore/well components, earthwork drilling, etc., can solve problems such as high operating cost, cutting operation failure, tool damage, etc., achieve good manufacturing and processing technology, and increase the success rate of cutting , the effect of wide cutting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

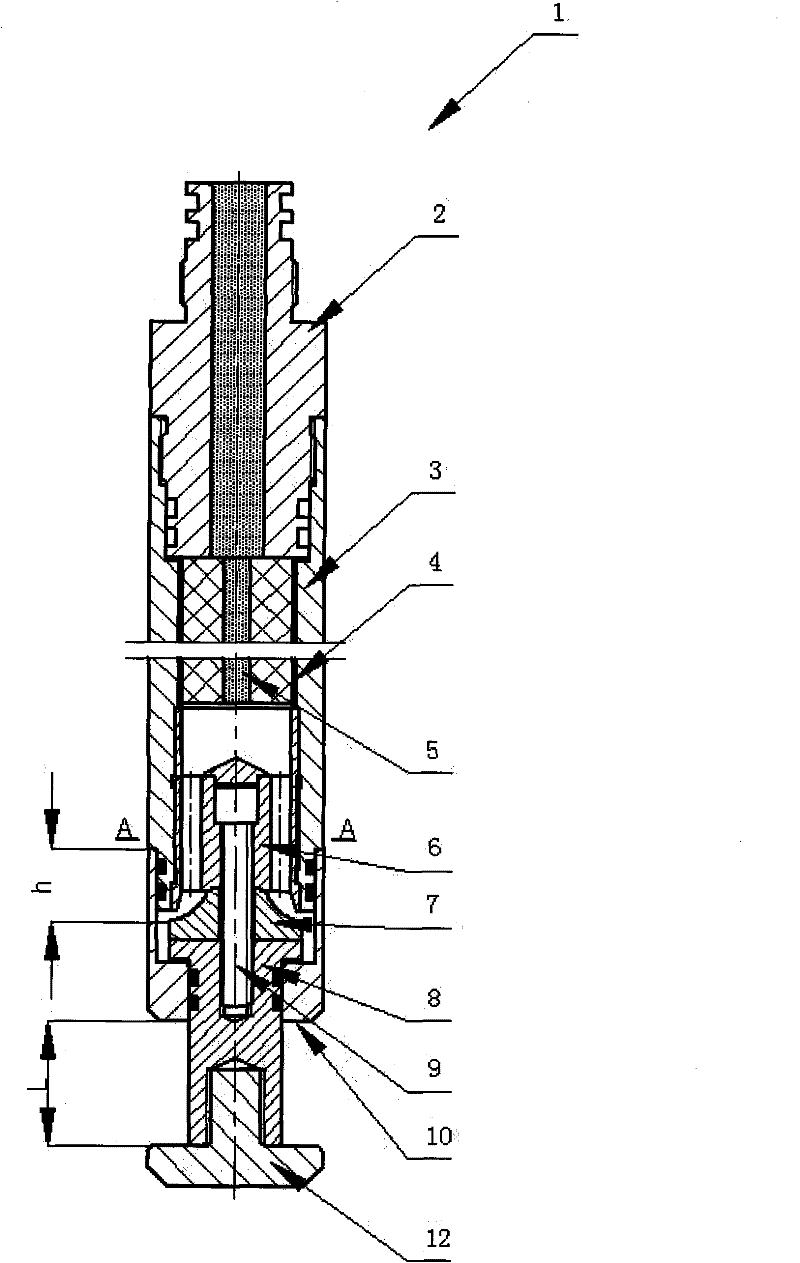

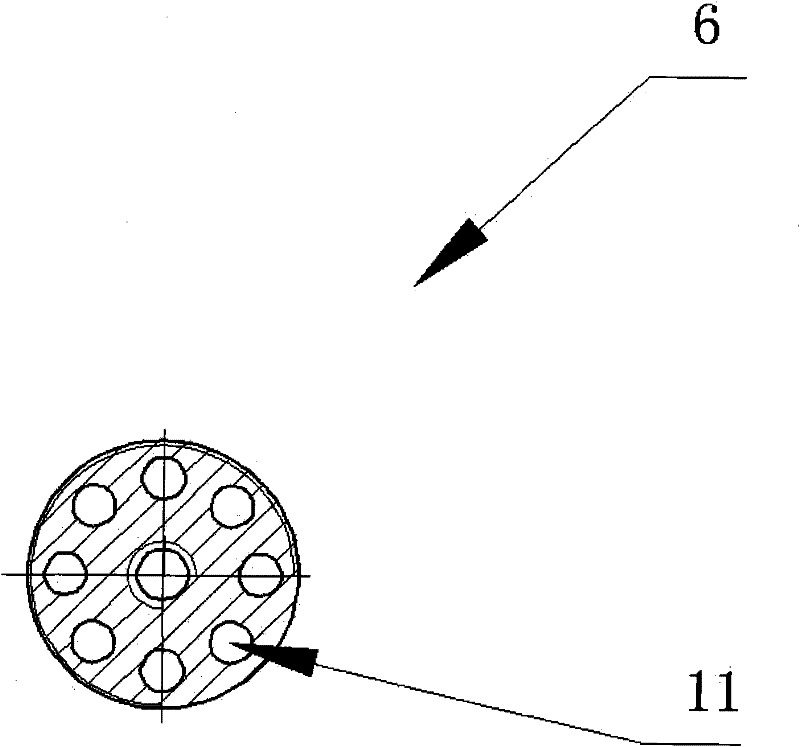

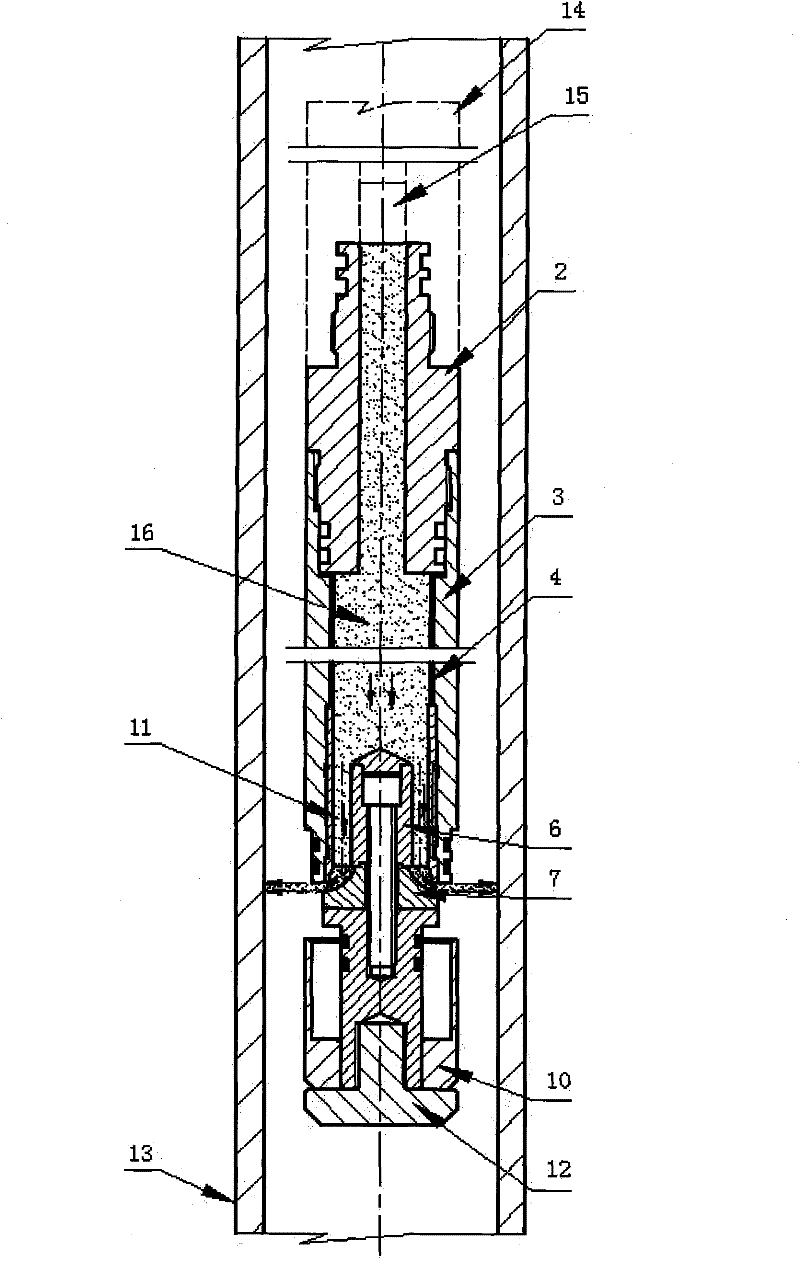

[0020] Such as figure 1 As shown, the non-explosive metal pipe annular cutting device 1 of the present invention mainly includes a cylindrical charge chamber 3, and the upper end of the charge chamber 3 is connected with an upper joint 2 for sealing and installing an ignition device, charge The lower end of the chamber 3 is connected with a sealing sliding sleeve 10; a layer of heat-resistant material 4 is attached to the inner surface of the charge chamber 3, and at least one charge unit 5 is filled in the charge chamber 3, and the other end of the charge chamber 3 is connected with a fluid Distribution deflector 6, deflector 6 is sequentially connected with a conical cone-shaped diverter 7 and tailstock 8 through screw 9, and tailstock 8 is connected with baffle plate 12; on the outside of diverter 7 and tailstock 8 , a sealing sliding sleeve 10 connected with the charge chamber 3 is provided to prevent oil and gas well fluids from entering the interior of the device. Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com