Method for automatic jump steel reheating of walking beam of stepping type heating furnace

A walking heating furnace and walking beam technology, which is applied in the field of hot-rolled slab heating, can solve problems such as watermarks, achieve the effect of eliminating watermark temperature differences and improving product dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

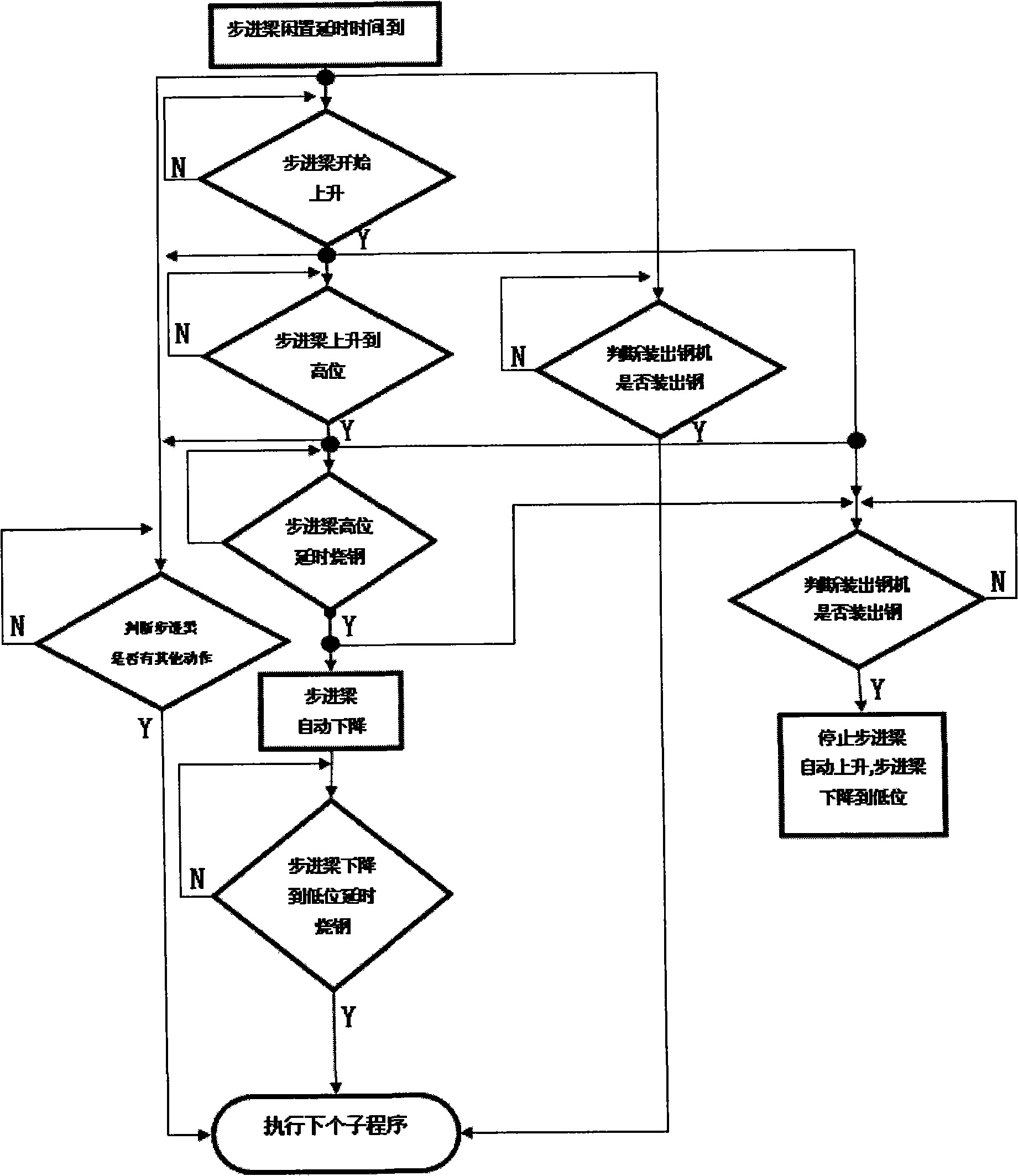

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] Now take the two heating furnaces adopting the large cross tapping method as an example, such as 1 # 3 to 5 pieces of steel are produced from the furnace, 2 # 3 to 5 pieces of steel are produced, 1 # Then 3~5 pieces of steel are produced from the furnace... In this way, steel is tapped in a large cross cycle. When one furnace is tapping steel, the other furnace is in an idle state, so that this furnace has enough time to perform the stepping function within 9 to 15 minutes. To effectively eliminate the slab watermark.

[0013] Such as figure 1 As shown, once the heating furnace is not loaded, tapped and the walking beam moves, the walking beam starts to enter the idle timing time, when there is no loading, tapping and The beam moves, and the walking beam begins to rise. Before the walking beam rises to the upper limit (high position), if the loading and tapping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com