Synthesis method for continuously producing N,N-dimethyl cyclohexyl amine

A technology of dimethylcyclohexylamine and a synthesis method, which is applied in the field of continuous production of N, can solve the problems of low utilization rate of raw materials and catalysts, difficult closed-circuit circulation, large energy consumption, etc. Good, low consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The synthetic method of this N,N-dimethylcyclohexylamine:

[0019] First prepare the catalyst:

[0020] Industrial Co / Al 2 o 3 The catalyst is a catalyst, numbered A1, and the composition (weight ratio) of the catalyst is: Cu is 5.0%, Co is 25.0%, Ti is 0.1%, Mn is 0.2%, Cr is 0.1%, and the rest is Al 2 o 3 .

[0021] Industrial Co / Al 2 o 3 The catalyst is a catalyst, coded as A2, and the composition (weight ratio) of the catalyst is: Cu is 5.0%, Co is 20.0%, Ti is 1.0%, Mn is 3.0%, Cr is 1.0%, and the rest is diatomaceous earth.

[0022] Industrial Co / Al 2 o 3 Catalyst is catalyst, numbering is A3, and the composition (weight ratio) of catalyst is: Cu is 5.0%, Co is 25.0%, and the rest is Al 2 o 3 .

[0023] 1), with cyclohexanol and dimethylamine as raw materials, with the Co / Al prepared above 2 o 3 A catalyst is a catalyst.

[0024] 2), the reaction is carried out in the vapor phase in the presence of hydrogen, using a continuous process.

[0025] 3) C...

Embodiment 2--- Embodiment 6

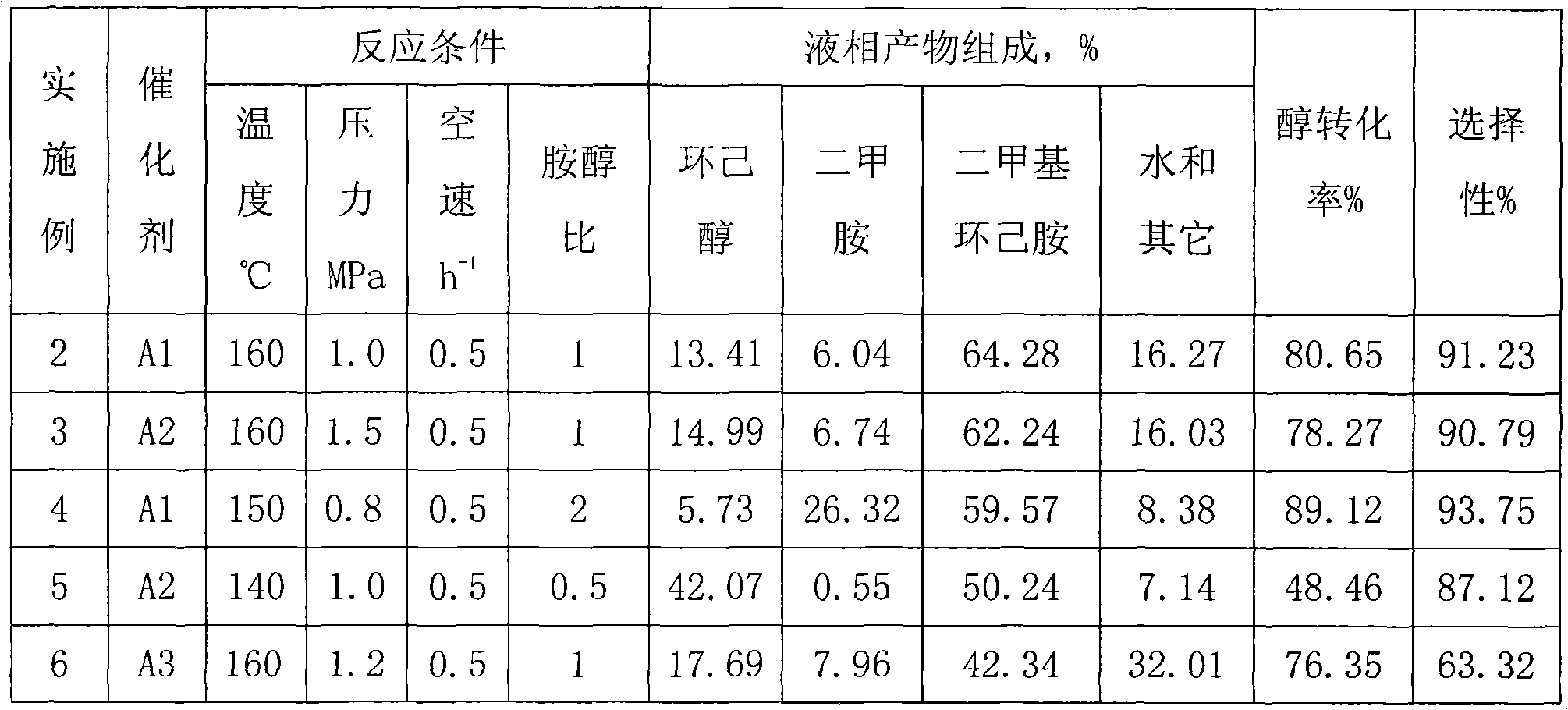

[0026] Embodiment 2 --- Embodiment 6: the catalyst in embodiment 1 is charged into a stainless steel reactor with an inner diameter of 25 mm and a length of 1500 mm. The catalyst loading height is 1200mm, and the catalyst loading volume is 600ml. The reaction raw materials are top-in and bottom-out. The material flowing out from the bottom of the reactor enters the separator after being condensed and cooled. The gas phase ammonia and hydrogen are discharged from the top of the separator. The mol ratio of a kind of mixed gas is 20%, and embodiment 5---6, the mol ratio that hydrogen accounts for three kinds of mixed gases is 30%. The composition was analyzed by gas chromatography, and the specific reaction conditions and results are listed in the table below.

[0027] Reaction conditions and results

[0028]

[0029] From the data in the above table, it can be seen that the content of Co in the catalyst is the main content, followed by the content of Cu, and a small amount ...

Embodiment 7

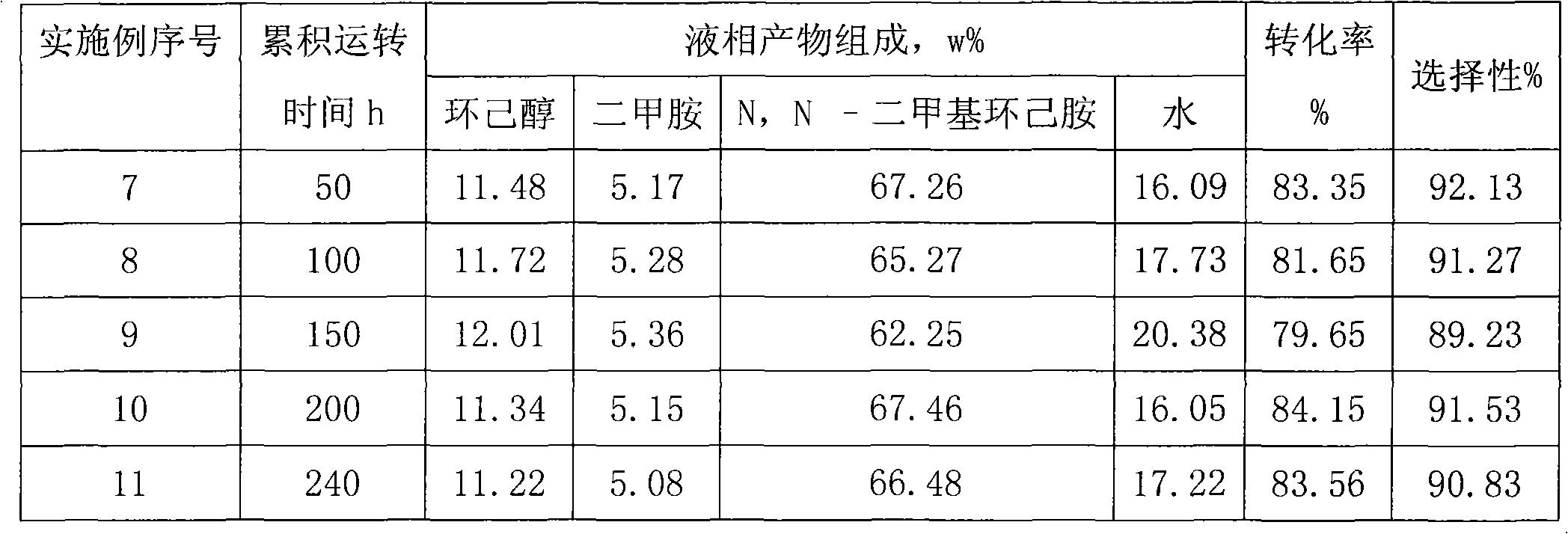

[0030] Example 7...Example 11: According to the device, process and catalyst described in Examples 2-6, the loading amount of the catalyst is 600ml, and a 240-hour stable operation test is carried out. Reaction pressure 1.0MPa, temperature 160°C, alcohol liquid space velocity 0.5h -1 , the amine-alcohol molar ratio is 1, and the molar ratio of hydrogen to the three mixed gases is 25%. The composition was analyzed by gas chromatography, and the specific reaction conditions and results are listed in the table below.

[0031] 240-hour stability operation test

[0032]

[0033] It can be seen from the data in the above table that under the process conditions, the conversion rate of the reaction is higher than 70%, the selectivity is higher than 80%, and the catalyst has better stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com