Porous ceramics and preparation method thereof

A technology for porous ceramics and ceramic powder, applied in the field of inorganic non-metallic ceramics, can solve the problems of difficult to meet requirements, complex process, high cost, and achieve the effects of satisfying machining and use requirements, good economy and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of porous alumina templates for preparing carbon nanotubes

[0038] 1. Preparation of porous alumina templates for the preparation of carbon nanotubes

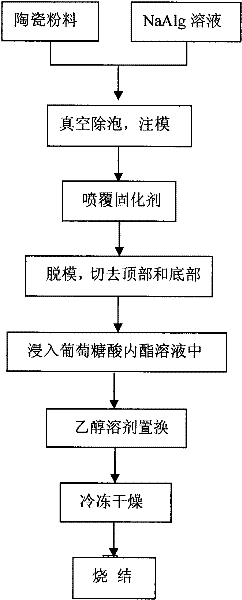

[0039] The preparation process is as figure 2 shown.

[0040] Ultrasonic dispersion of 10g of alumina powder in 190g of sodium alginate solution with a concentration of 1.5% (mass percentage content), at this time, the mass ratio of sodium alginate solution to ceramic powder is 190:10=19:1, ball milling 4h, forming 200g of slurry with a solid phase content of 5% (mass percentage), wherein the solid phase content = solid phase powder mass / total slurry weight, total slurry weight = solid phase powder mass + sodium alginate solution mass .

[0041] Then inject the uniformly dispersed slurry into the mold (beaker), and spray the CaCl with a concentration of 2mol / L 2 Aqueous solution, after forming a thin film to cover the slurry surface, fill the remaining curing agent into the mold. Wherein, ...

Embodiment 2

[0057] Embodiment 2: preparation and analysis of hydroxyapatite (HAP) porous ceramics

[0058] 1. Preparation of HAP porous ceramics

[0059] The preparation process is as figure 2 shown.

[0060] Add 10g HAP powder in the sodium alginate solution that 90g concentration is 1.5% (mass percentage), at this moment the mass ratio of sodium alginate solution and HAP powder is 9: 1, ball mills 4h, and the formation solid phase content is 10% ( mass percent) slurry 100g.

[0061] Then inject the slurry into the mold, and evenly spray CaCl with a concentration of 1.5mol / L on the surface of the slurry 2 Aqueous solution, after the curing agent covers the surface of the slurry, fill the remaining curing agent into the mold. Wherein, the total amount of the curing agent used is 25 g, that is, the mass ratio of the curing agent to the slurry is 1:4. After standing for 2 days, the mold was demoulded, and the top and bottom were cut off to obtain a wet base.

[0062] Put the wet bill...

Embodiment 3

[0069] Embodiment 3: Preparation of alumina porous ceramic disk

[0070] 1. Preparation of alumina porous ceramic discs

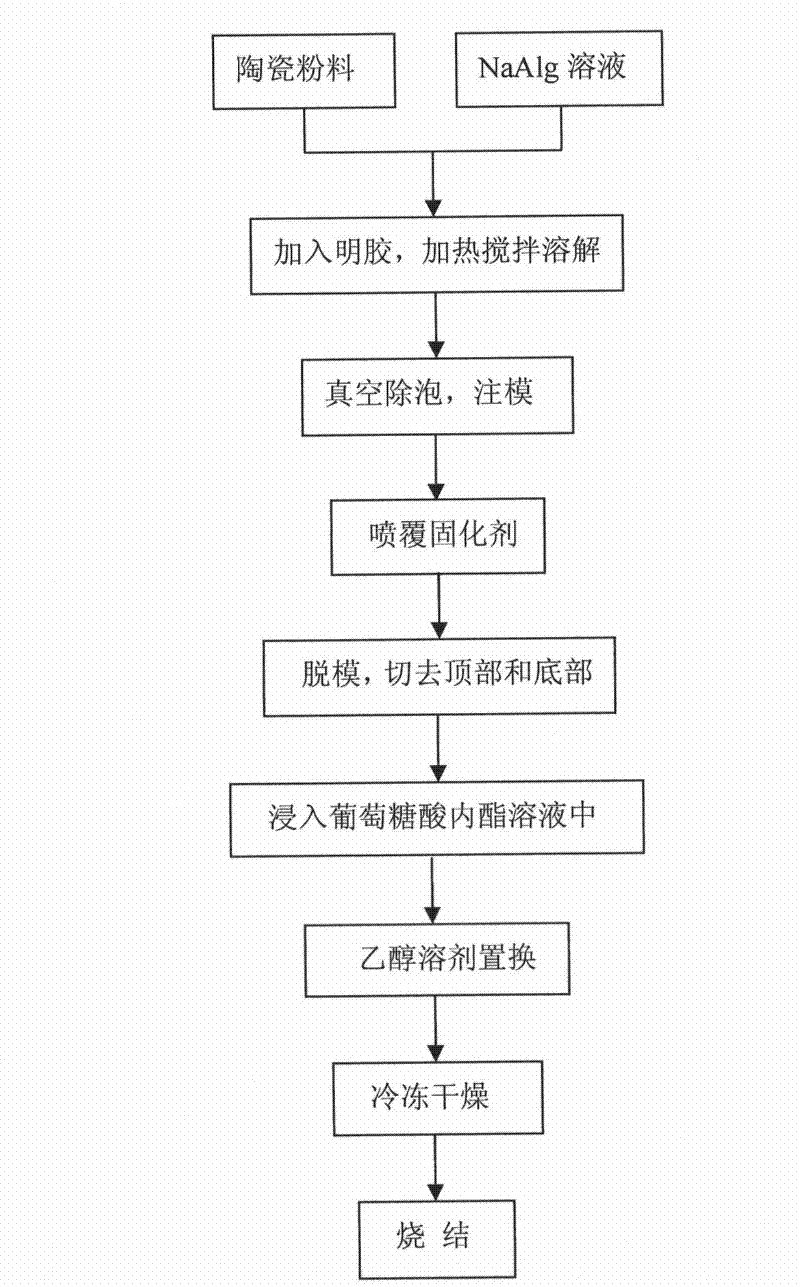

[0071] The preparation process is as image 3 shown.

[0072] 37.5g (average particle size is 350nm) of alumina powder ultrasonically dispersed in 87.5ml of water to form a 125g suspension, then mixed with 125g of sodium alginate solution with a concentration of 2% (mass percentage), the used sodium alginate solution and The mass ratio of the alumina powder used was 125:37.5=10:3. After ball milling for 4 hours, 250 g of a slurry with good fluidity and a solid phase content of 15% (mass percentage) was formed.

[0073] Add 2.5 g of gelatin (Beijing Chemical Reagent Company) to the above slurry, the gelatin accounts for 1% by mass of the slurry, and heat to 60° C. to fully dissolve.

[0074] The slurry containing gelatin is injected into the mold, and the curing agent is uniformly sprayed on the surface of the slurry after injection molding, and the curin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com