Honeycomb briquette stacking machine

A technology of coal lotion and gearbox, applied in the direction of mechanical equipment, stacking of objects, belts/chains/gears, etc., can solve the problems of high labor intensity and poor labor environment, and achieve high labor intensity, saving motor costs, and saving The effect of wage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

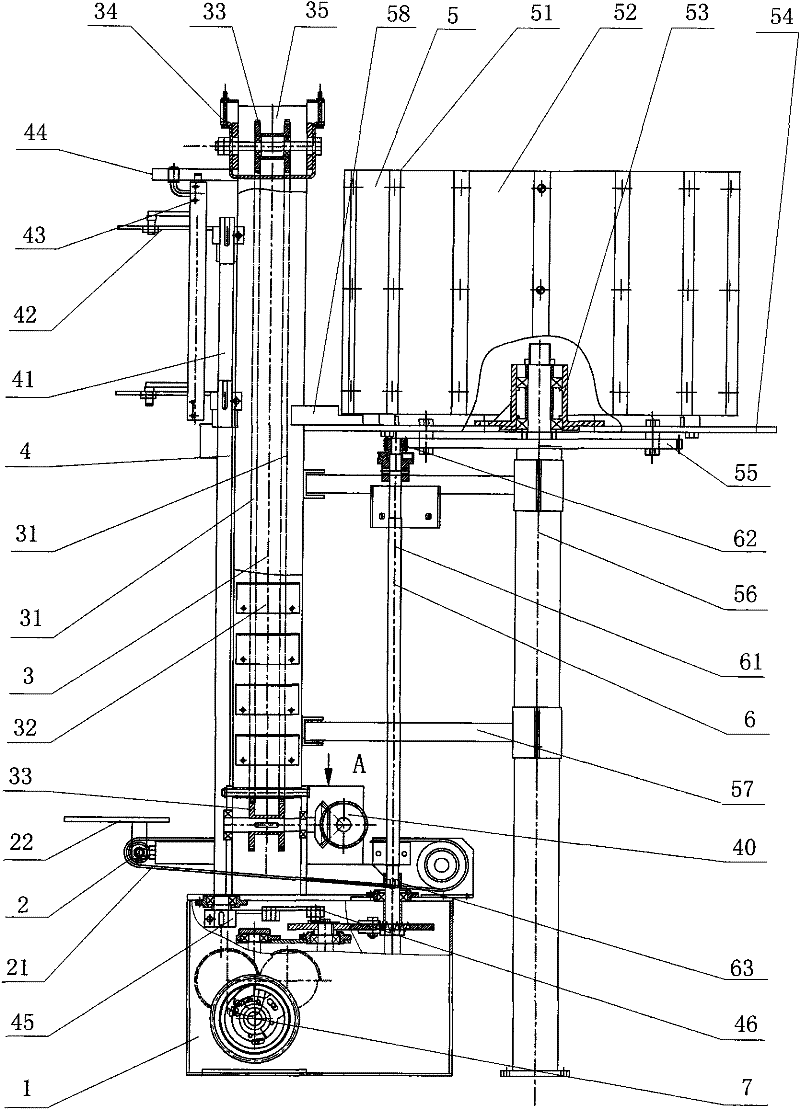

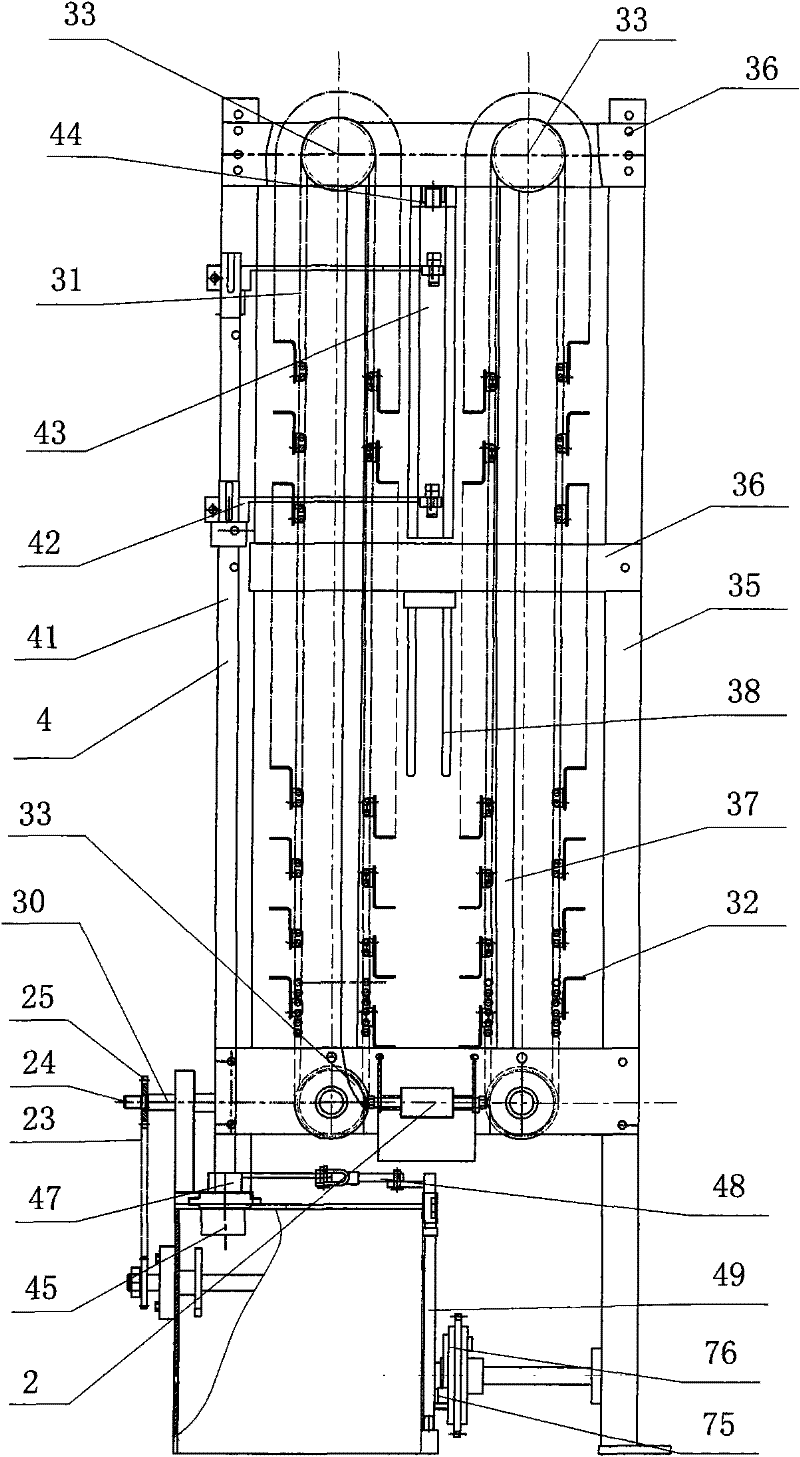

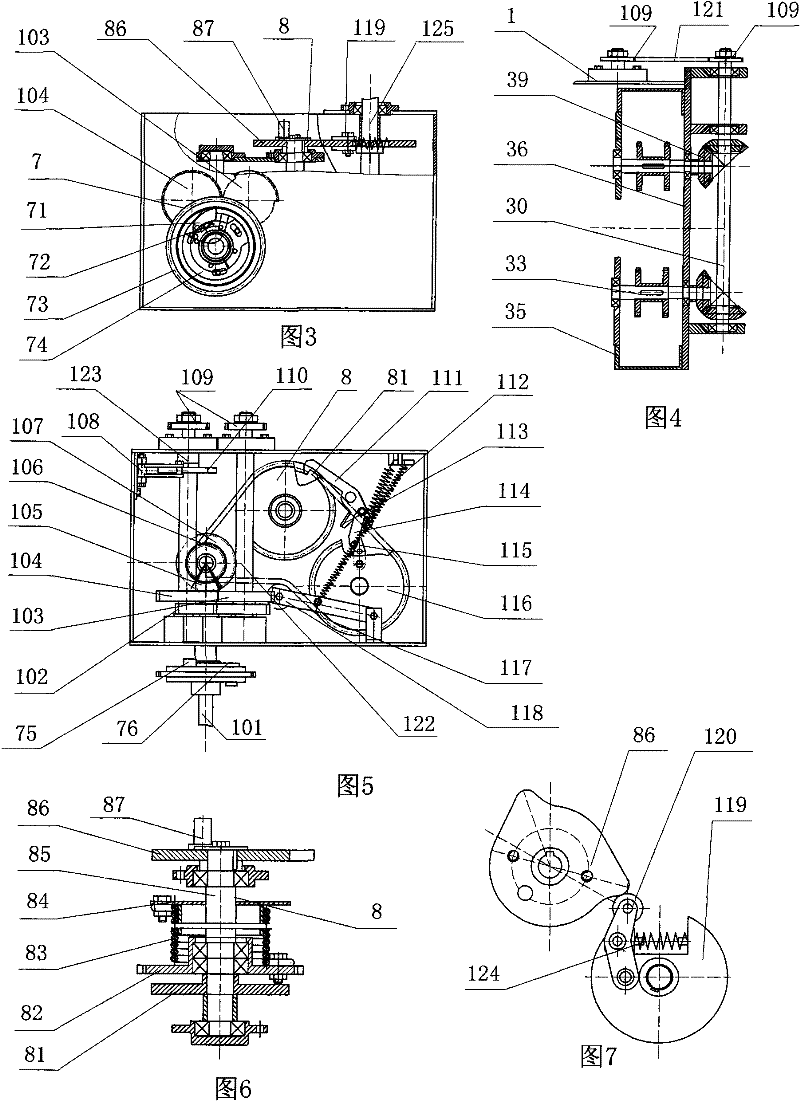

[0029] by attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7Shown, a kind of lotus root coal stacking machine, comprises gearbox 1, belt drive mechanism 2, lifting mechanism 3, pushes lotus root coal mechanism 4, turntable mechanism 5, transmission vertical shaft 6, clutch 7, accumulator 8; Gearbox 1 Including fixed gear I102 and bevel gear I105 on the power shaft 101, gear I102 meshes with gear I102 on the transmission shaft I122, gear with missing teeth 103 on the transmission shaft I122 meshes with gear II104 of the transmission shaft II123, transmission shaft I122 is in the gearbox 1 Externally connected sprocket Ⅰ109, the tooth-missing gear 103 leaves 1 / 3 of the teeth, when the tooth-missing gear 103 rotates a circle, the gear Ⅱ 104 of the transmission shaft Ⅱ 123 rotates 1 / 3 of the circle, and the three-groove wheel 110 is fixed on the transmission shaft Ⅱ 123 , the roller of the locking mechanism 108 rolls on the arc surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com