Tire tread of motortruck

A technology for tire treads and trucks, applied to tire treads/tread patterns, tire parts, vehicle components, etc., can solve the problems of high fuel consumption and easy drop-off of lateral patterns, and achieve increased ground contact area and improved attachment Concentrate on the effect of reducing rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

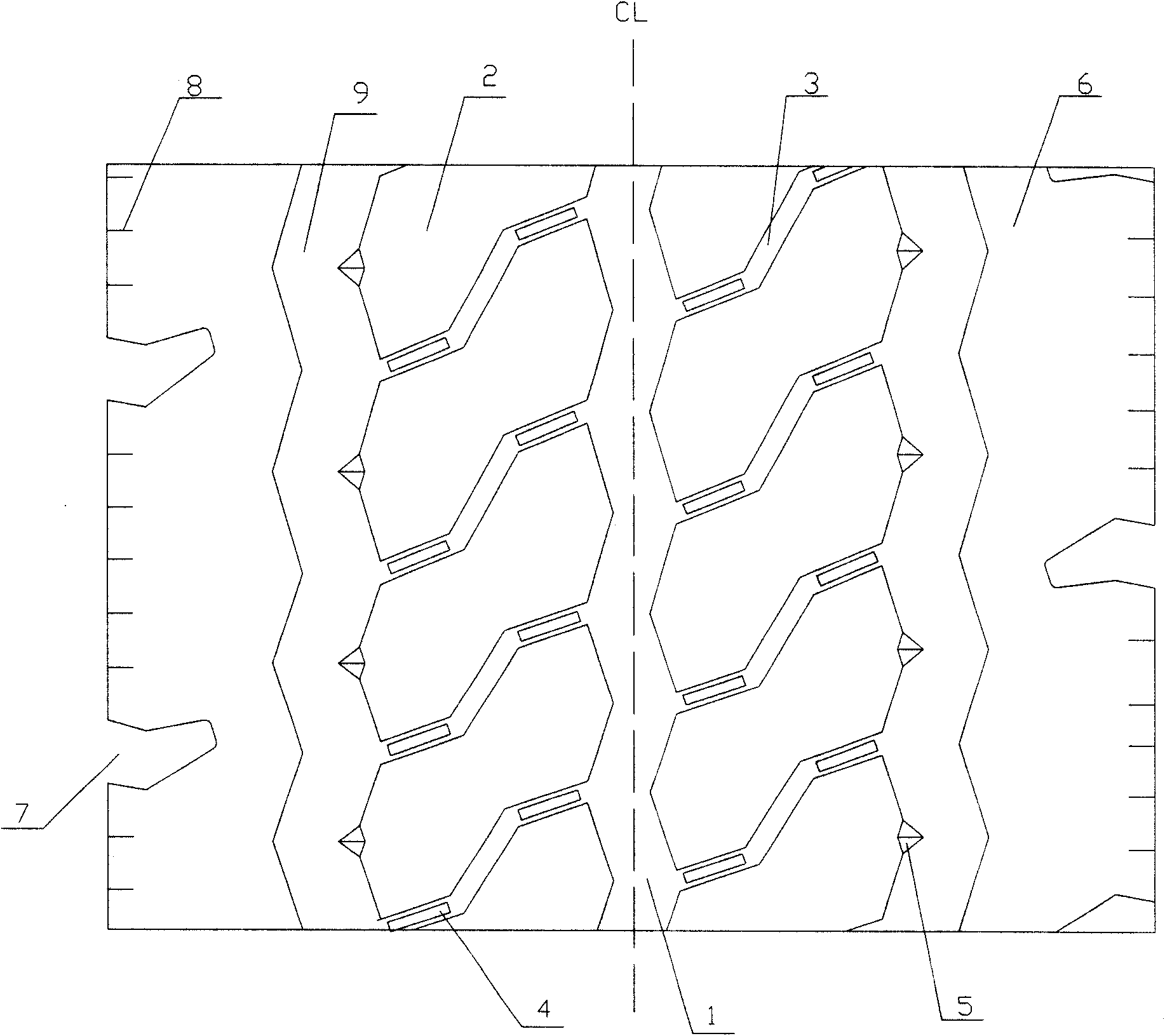

[0015] The tread of a truck tire includes a central longitudinal circumferential groove 1 set at the central position of the tread, that is, the center line CL of the tread. The central longitudinal circumferential groove 1 divides the tire tread into two symmetrical parts. The central longitudinal circumference On the left and right sides of the pattern groove 1, the side pattern blocks 2 and the shoulder pattern blocks 6 are regularly arranged in order from the inside to the outside, and the side pattern blocks 2 and the shoulder pattern blocks 6 are separated by a longitudinal circumferential groove 9. The pattern blocks 2 on both sides are separated by auxiliary pattern grooves 3 ; the shoulder pattern blocks 6 form an integral structure along the circumferential direction of the tire tread.

[0016] The side pattern blocks 2 are inclined "8"-shaped structures. The inclination angle of the side blocks 2 relative to the tread centerline CL is 20°. The side corner of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com