Laminated type laminating machine

A laminator and lamination technology, applied in the direction of lamination, lamination device, layered products, etc., can solve the problems of long waiting time, low work efficiency, large number of laminators, etc., to reduce work procedures, The effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

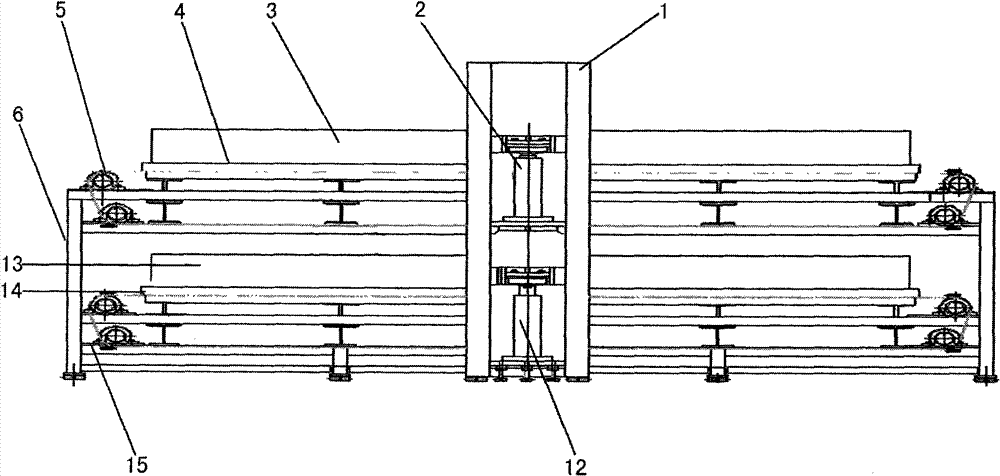

[0012] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

[0013] See attached figure 1 The stacked laminator shown includes a frame 6 connected to vertical frames 1 located symmetrically on both sides of the middle. In this embodiment, the upper and lower parts of the vertical frame 1 both sides are symmetrically equipped with upper and lower floor lifting devices composed of the upper oil cylinder 2 and the lower floor oil cylinder 12; ) are equipped with an upper vacuum chamber 3 and a lower vacuum chamber 13 respectively, and a layer composed of an upper heating platform 4 and a lower heating platform 14 is respectively provided at the positions corresponding to the upper upper vacuum chamber 3 and the lower vacuum chamber 13 pressure device. An upper conveying system 5 and a lower conveying system 15 are respectively arranged on the upper layer heating platform 4 and the lower layer heating platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com