Drilling tool wellhead safety protection control device

A technology of safety protection and control device, which is applied to the automatic control system of drilling, drilling equipment, earth-moving drilling, etc., can solve the problems of wasting working time, unable to arrange the replacement of drilling tools, etc., so as to prevent breaking and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

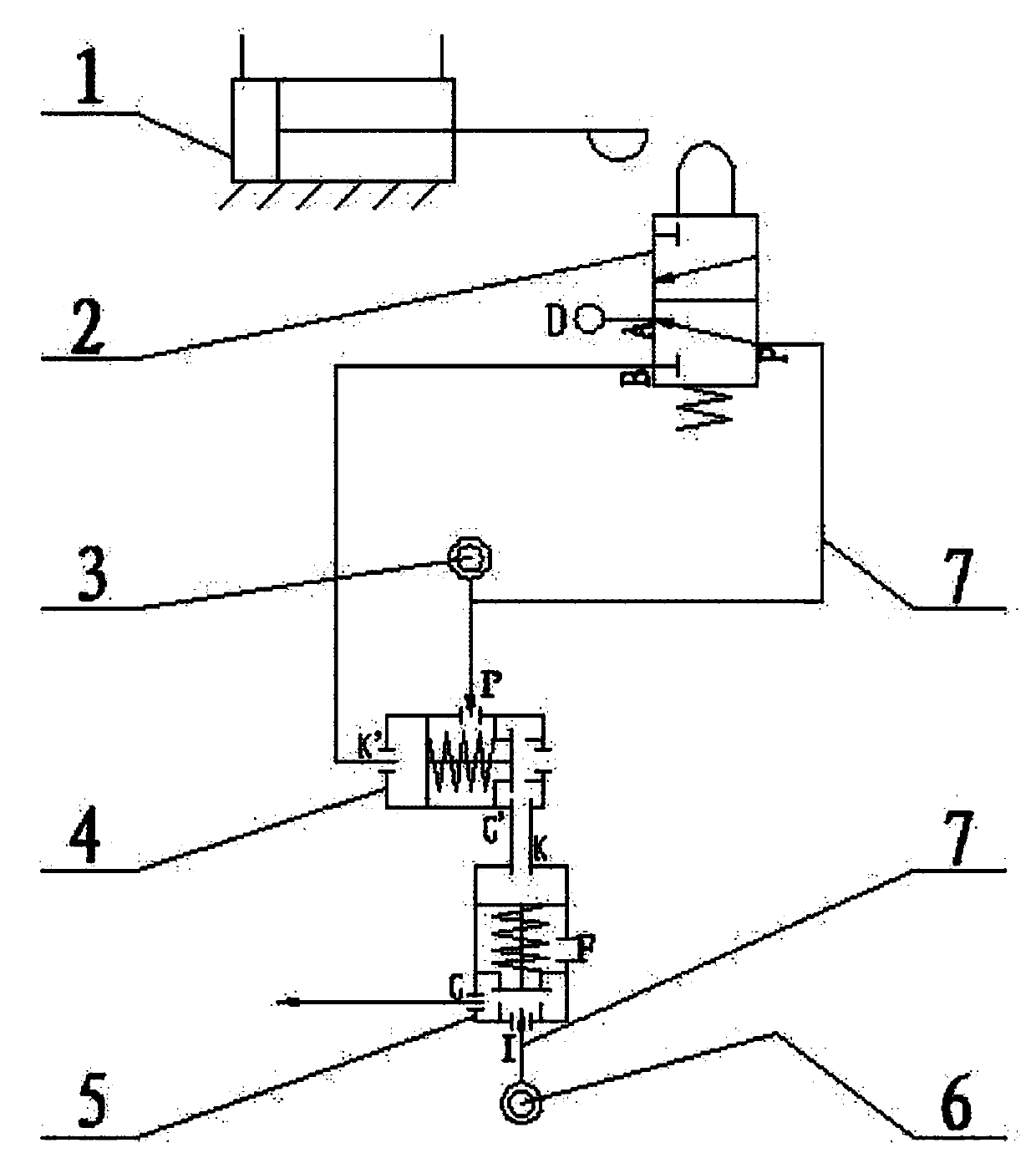

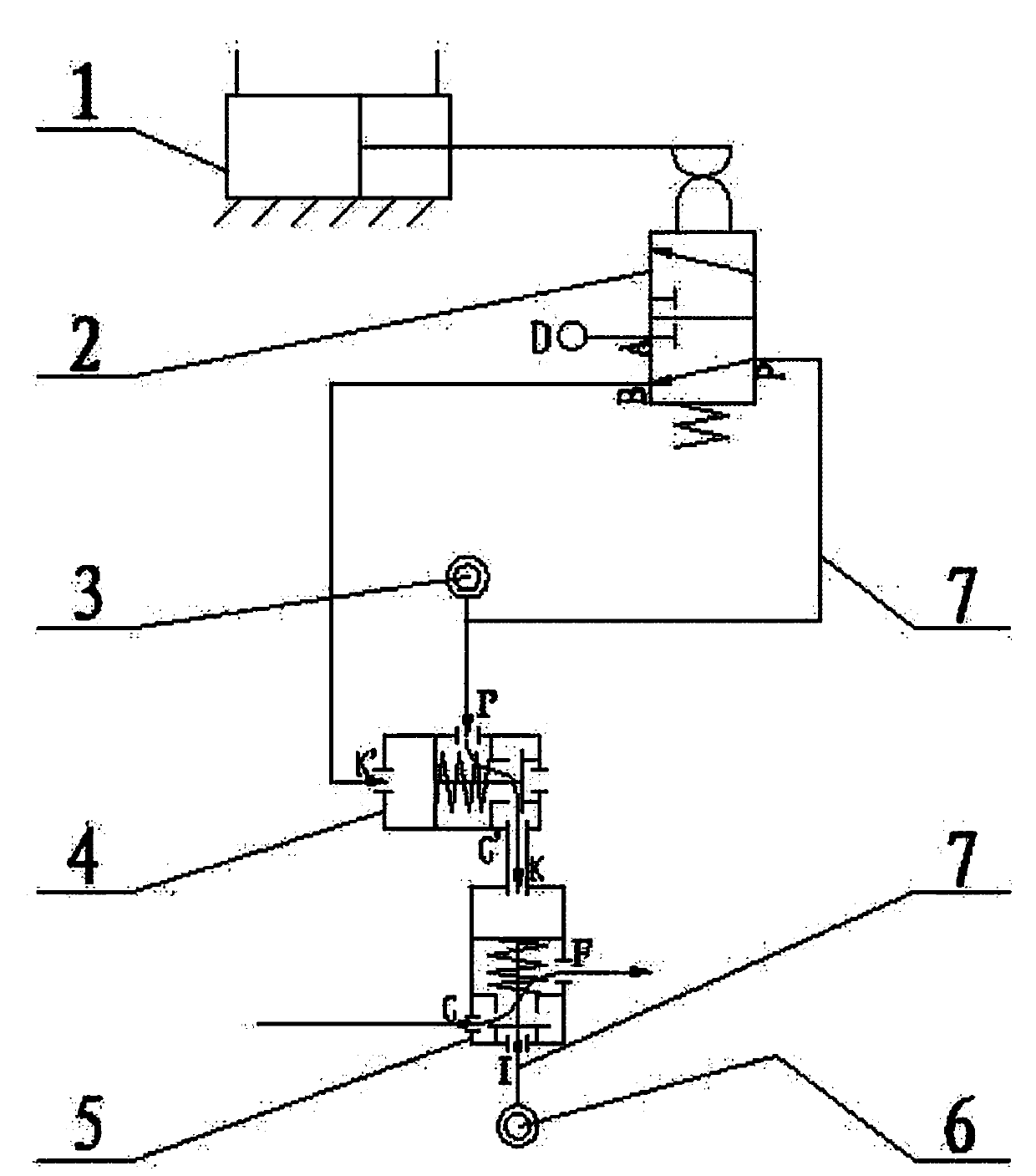

Method used

Image

Examples

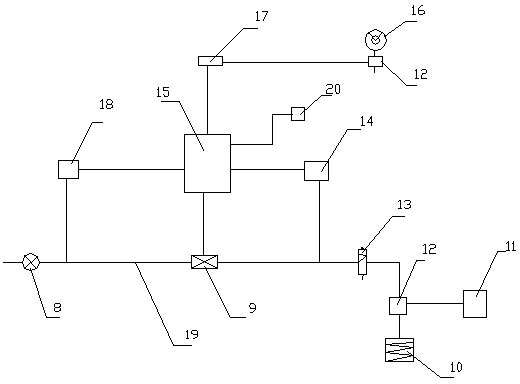

Embodiment 1

[0042] In this implementation, a hydraulic control valve 8, a normally closed air control device 18, a solenoid valve 9, a normally open air control device 14, a button valve 13 and a tee 12 are sequentially arranged on the air circuit 19 of the brake cylinder of the drilling rig. The air inlet of the three-way 12 is communicated with the button valve 13, and the other two exhaust ports are connected with the brake cylinder 11 of the anti-collision crane, and one is communicated with the brake cylinder 10 of the drilling rig; the button valve 13 is a three-way valve, The two openings are connected to the air circuit 19 of the brake cylinder 10 of the drilling rig, and the other opening is used for exhaust. Just press the button valve 13, and the compressed gas can be discharged from the button valve; the solenoid valve 9 is connected to the control system 15 , the normally open air control device 14, the normally closed air control device 18 and the pressure sensor 17 are all c...

Embodiment 2

[0045] In this embodiment, the difference from Embodiment 1 is that there are two solenoid valves 9, which are connected in parallel to the air circuit 19 of the brake cylinder of the drilling rig. The purpose is that when one of the solenoid valves 9 is damaged, the other solenoid valve is normal. Work without affecting the normal operation of the system, and it is also convenient for workers to replace the solenoid valve.

Embodiment 3

[0047] In this embodiment, the difference from Embodiment 1 is that there are three solenoid valves 9, which are connected in parallel to the air circuit 19 of the brake cylinder of the drilling rig.

[0048] Electromagnetic valve 9 can be multiple, is not limited to one to three, as long as it is connected in parallel on the air circuit 19 of the drilling rig brake cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com