Method for modifying titanium-silicon molecular sieve

A titanium-silicon molecular sieve and modification technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of low catalyst activity, low effective utilization rate, poor stability, etc., and achieve simple and easy operation, Good catalytic oxidation activity, easy modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

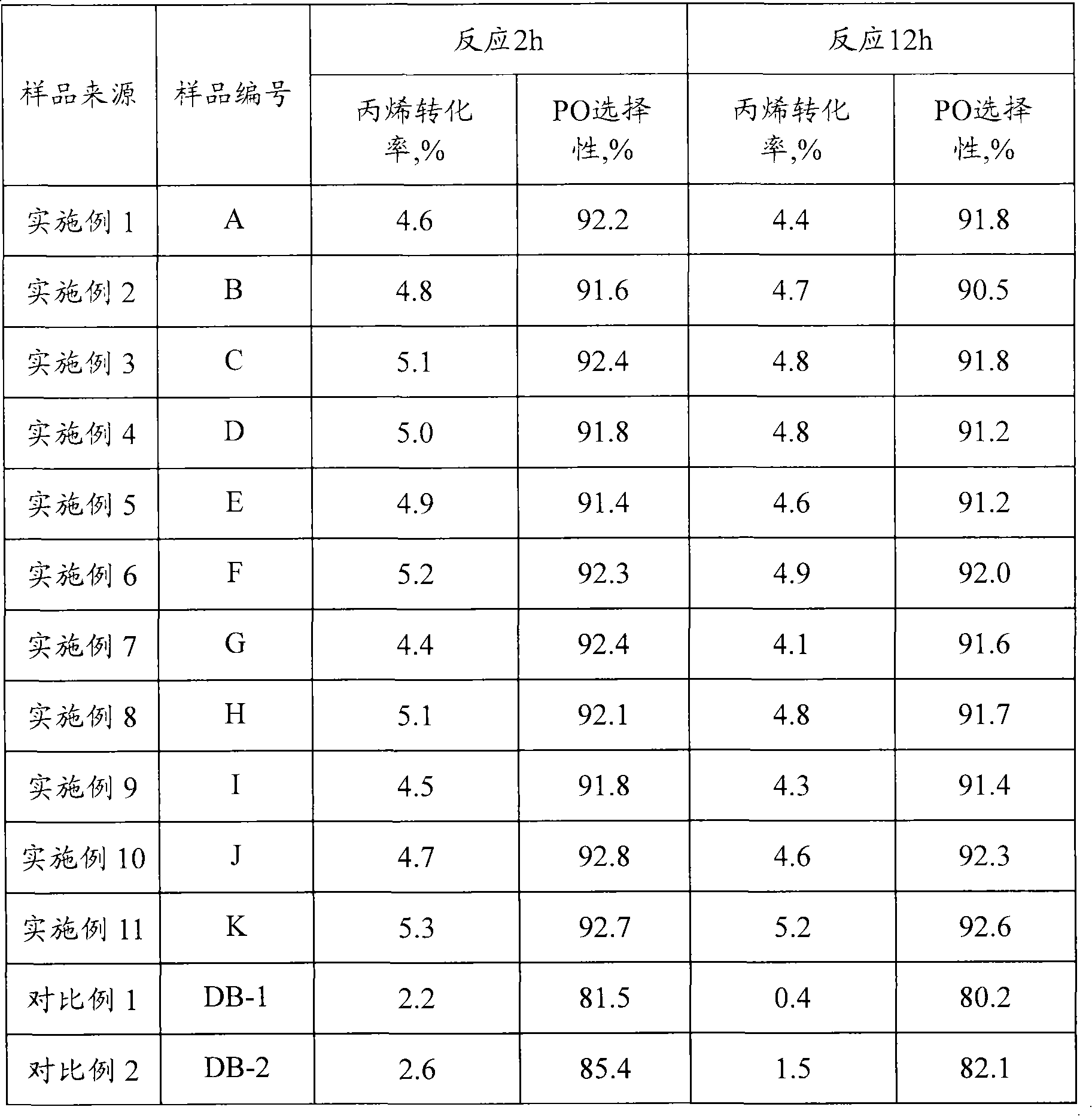

Examples

Embodiment 1

[0033] Get 10 grams of titanium-silicon molecular sieve TS-1, a concentration of 0.01g / mL (in terms of palladium atoms) ammonium nitrate palladium complex solution and hexadecyltrimethylammonium bromide to join the tetrapropylammonium hydroxide Stir in an aqueous solution (mass percentage concentration 10%) to obtain a mixed solution 1, wherein titanium silicon molecular sieve (gram): hexadecyltrimethylammonium bromide (mole): tetrapropyl ammonium hydroxide (mole): ammonium nitrate Palladium complex (g, calculated as palladium): water (mol) = 100: 0.2: 0.005: 0.5: 1000. At room temperature, ethyl orthosilicate, butylenediamine and water were stirred for 50 minutes according to the ratio of ethyl orthosilicate (mol): butylenediamine (mol): water (mol) = 1: 4.5: 200, and mixed For liquid 2, mix liquid 1 and liquid 2 according to the ratio of molecular sieve (g): Si (mol) = 200: 1, put them into a stainless steel reactor, seal them, and conduct hydrothermal treatment at a tempera...

Embodiment 2

[0035] Take 10 grams of titanium-silicon molecular sieve TS-1, a palladium chloride solution with a concentration of 0.01 g / mL (calculated as palladium atoms) and polyacrylate, and add it to an aqueous solution of hexamethylenediamine (15% by mass) and stir evenly to obtain a mixture. Liquid 1, wherein titanium-silicon molecular sieve (gram): polyacrylate (mol): sodium hydroxide (mol): palladium chloride (gram, calculated as palladium): water (mol) = 100: 0.9: 1.0: 0.15: 1600 . At 45°C, methyl orthosilicate, tetrapropylammonium hydroxide and water were mixed according to the ratio of methylorthosilicate (mol): tetrapropylammonium hydroxide (mol): water (mol) = 1: 1.8: 300 Proportionally stirred for 30 minutes to obtain mixed solution 2, then mixed solution 1 and mixed solution 2 according to the ratio of molecular sieve (gram): Si (mol) = 500: 1 and then put into a stainless steel reactor to seal, at a temperature of 180 ° C Hydrothermal treatment under autogenous pressure fo...

Embodiment 3

[0037] Get 10 grams of titanium-silicon molecular sieve TS-1, a concentration of 0.01g / mL (in terms of palladium atoms) palladium nitrate solution and Tween 80 to join the aqueous solution of tetrapropylammonium hydroxide and n-butylamine (mass percentage concentration 10%) Mixed solution 1 was obtained by stirring in the medium, wherein titanium-silicon molecular sieve (gram): protective agent (mole): organic amine (mole): palladium source (gram, calculated as palladium): water (mole) = 100: 0.03: 0.1: 0.05 : 550; At room temperature, silica sol, butylenediamine and water are mixed according to silica sol (mole, as SiO 2 (meter): butyldiamine (mol): water (mol) = 1: 1.2: 450 ratio and stirred for 80 minutes to obtain mixed solution 2; : 1 ratio and put into a stainless steel reactor and seal it, hydrothermally treat 120h at a temperature of 120°C and autogenous pressure, filter, wash, then dry at 150°C for 3h, and roast in a nitrogen atmosphere at 350°C for 5h to obtain Modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com