Method and device thereof for stably burning various fuel gases with high-low calorific values

A technology with stable combustion and low calorific value, applied in combustion methods, gas fuel burners, burners, etc., to enhance air disturbance, reduce direct emissions, and utilize efficiently and reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

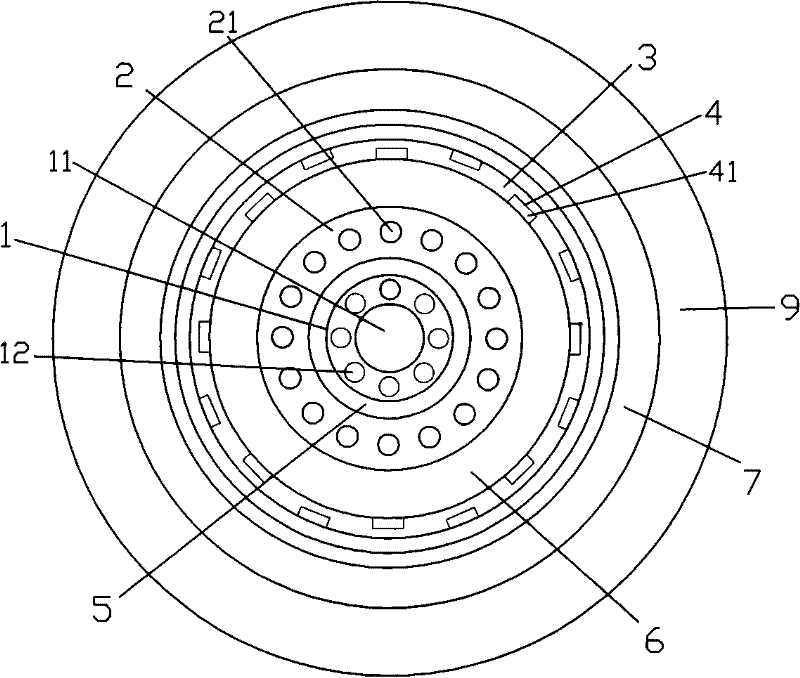

[0029] see figure 1 , figure 2 , the stable combustion method of various types of high and low calorific value gases in the present invention is divided into four independent gas channels according to the high, medium and low calorific value gases, arranged in a concentric manner, and the nozzles of each gas channel at the exit of the combustion device are arranged in a multi-layer spaced manner. Air ducts are set between them to form multi-channel, independent, multi-hole intersecting jets to realize high-stable combustion of various types of high, medium and low calorific value gases.

[0030] Specifically, the stable combustion device for various types of high-calorific-value gas of the present invention includes a central pipe 1, which is the first gas channel for passing high-calorific-value gas. Boundary nozzle 12, the peripheral nozzle 12 is a diffuser structure; the circumferential gas channel 2, which is arranged outside the central tube 1, is the second gas channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com